As more and more cities declare low-emission zones, Scania is ready to help contractors and operators meet these environmental concerns with a new G 410 B8x4*4 tractor unit that runs on compressed natural gas. The truck uses Scania’s latest OC series engine which delivers 305kW and 2,000Nm of power … in line with diesel engines of a similar size. However, and more importantly, emissions are only around 15% of a similar diesel engine, making the vehicle ideal for companies running in urban locations.

April 26, 2018

Read time: 2 mins

As more and more cities declare low-emission zones, 759 Scania is ready to help contractors and operators meet these environmental concerns with a new G 410 B8x4*4 tractor unit that runs on compressed natural gas.

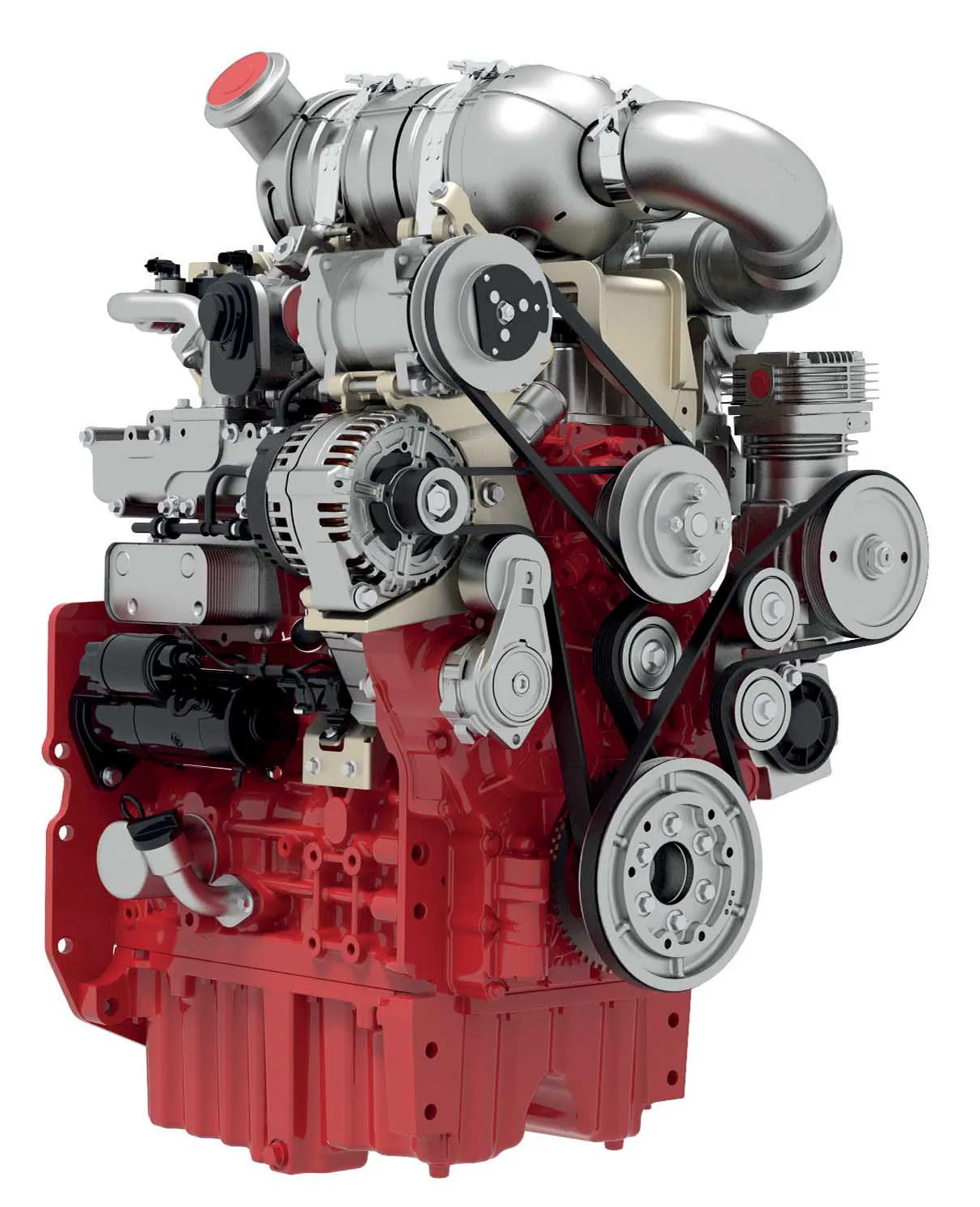

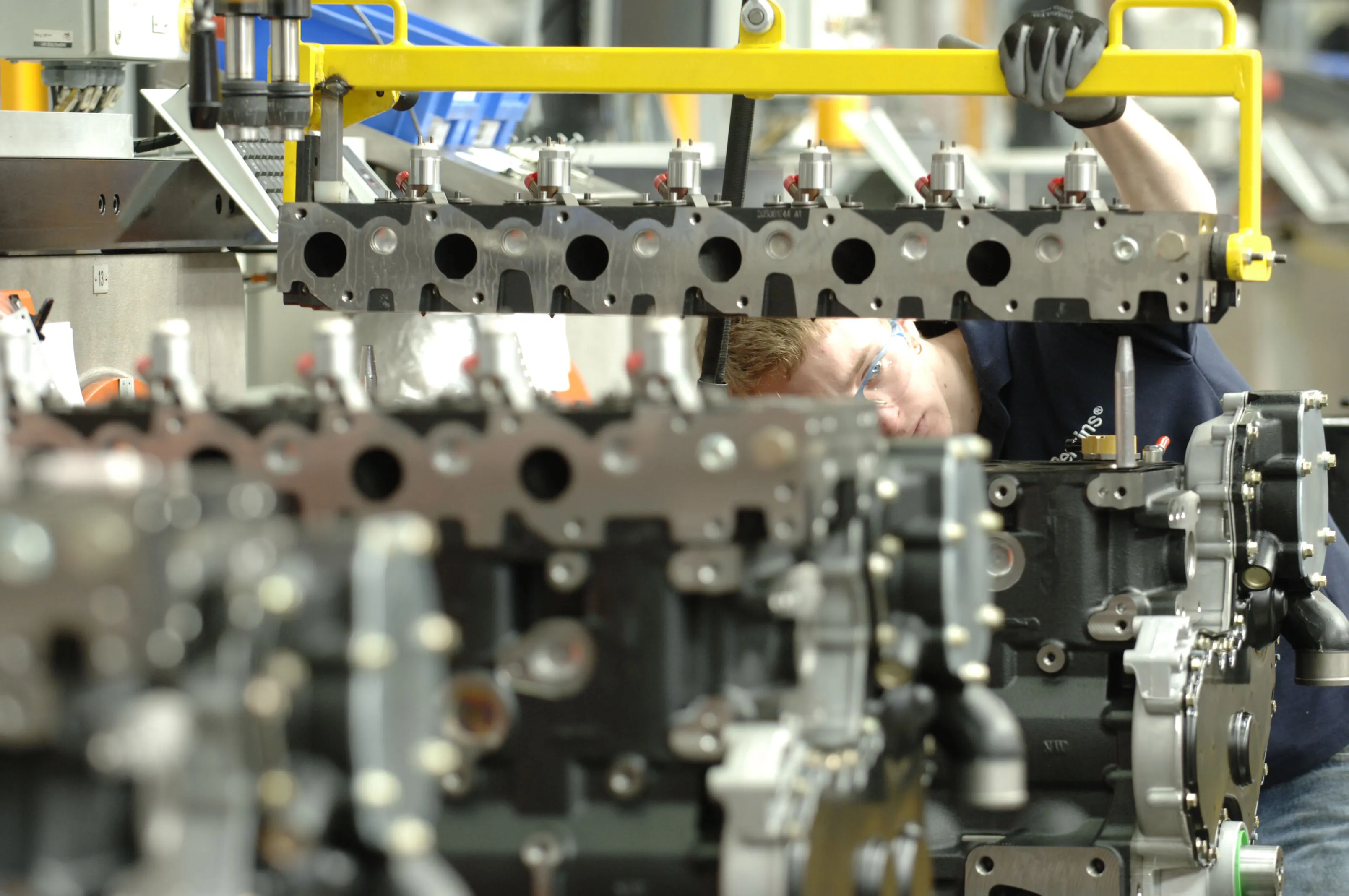

The truck uses Scania’s latest OC series engine which delivers 305kW and 2,000Nm of power … in line with diesel engines of a similar size.

However, and more importantly, emissions are only around 15% of a similar diesel engine, making the vehicle ideal for companies running in urban locations.

With eight tanks of CNG (compressed natural gas) on board, the G 410 B8x4*4 has a range of up to 500km. Both LNG (liquefied natural gas) and CNG tanks can be ordered directly from Scania.

LNG always provides greater range, as a significantly larger amount of fuel can be obtained.

The CNG solution is more than sufficient for many customers, such as those whose assignments involve regional operations with a return to the home base and the refuelling point every day.

But the kilometres that can be achieved from a full tank depends also on the type of operations involved, the weight of the load and how hilly the route is.

A particular safety aspect is that Scania’s engineers have turned the tank valves backwards, away from the direction of travel. This is a simple but well-thought-out detail that reduces the risk of the valves becoming damaged when hit by an external impact.

The truck uses Scania’s latest OC series engine which delivers 305kW and 2,000Nm of power … in line with diesel engines of a similar size.

However, and more importantly, emissions are only around 15% of a similar diesel engine, making the vehicle ideal for companies running in urban locations.

With eight tanks of CNG (compressed natural gas) on board, the G 410 B8x4*4 has a range of up to 500km. Both LNG (liquefied natural gas) and CNG tanks can be ordered directly from Scania.

LNG always provides greater range, as a significantly larger amount of fuel can be obtained.

The CNG solution is more than sufficient for many customers, such as those whose assignments involve regional operations with a return to the home base and the refuelling point every day.

But the kilometres that can be achieved from a full tank depends also on the type of operations involved, the weight of the load and how hilly the route is.

A particular safety aspect is that Scania’s engineers have turned the tank valves backwards, away from the direction of travel. This is a simple but well-thought-out detail that reduces the risk of the valves becoming damaged when hit by an external impact.