Eaton has launched a radial piston motor suited for offshore, marine, metal recovery, mining, pulp and paper, and off-highway stationary applications.

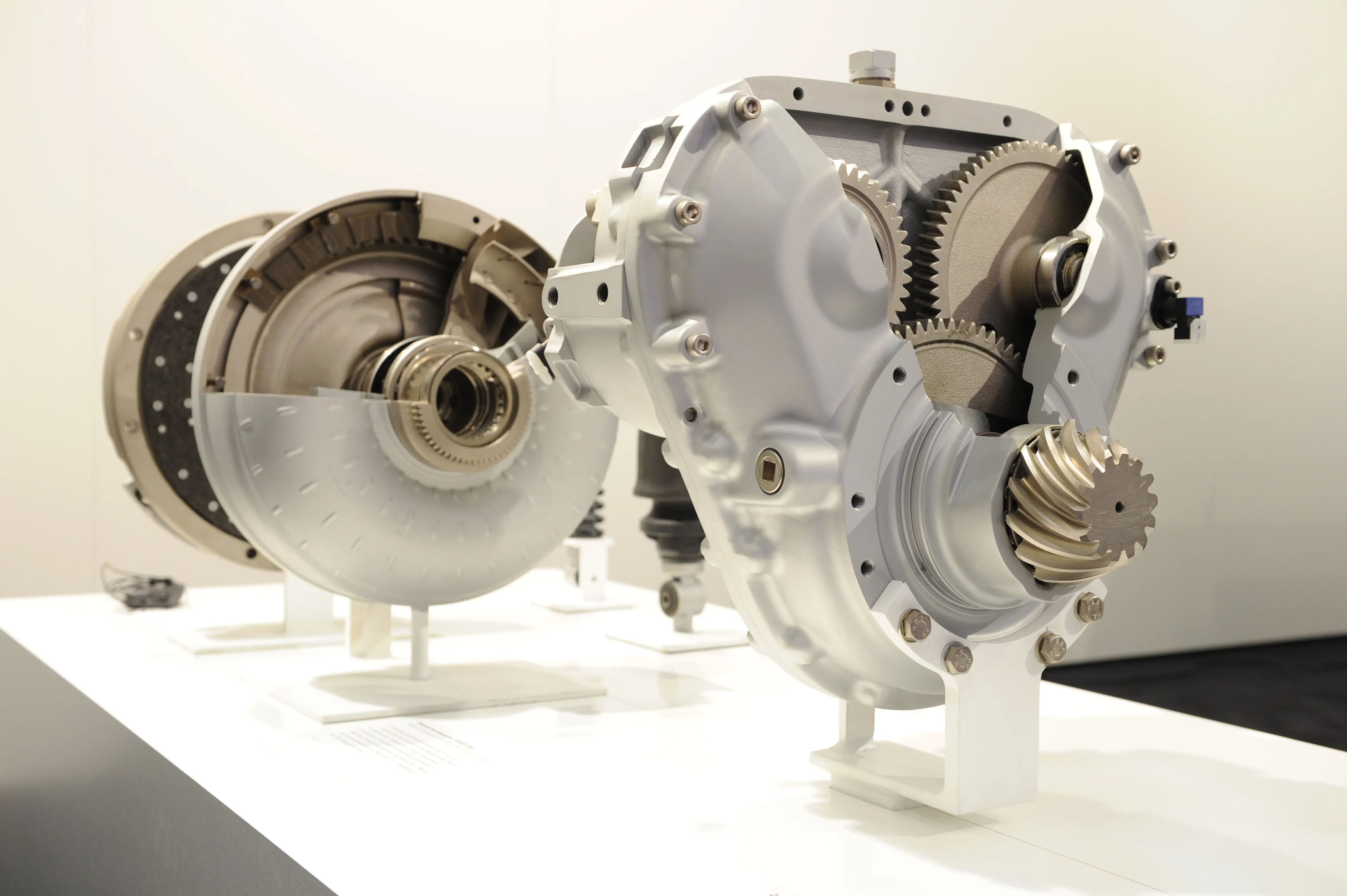

The Hydre-MAC is a low-speed, high-torque, direct-drive, radial piston motor with a cam lobe design. The motor uses less energy to deliver more power when needed.

The Hydre-MAC motor, created using a MacTaggart Scott heavy-duty motor design, combines MacTaggart Scott’s motor expertise with Eaton’s industry knowledge – particularly in oil and gas, mining

March 6, 2014

Read time: 2 mins

The Hydre-MAC is a low-speed, high-torque, direct-drive, radial piston motor with a cam lobe design. The motor uses less energy to deliver more power when needed.

The Hydre-MAC motor, created using a MacTaggart Scott heavy-duty motor design, combines MacTaggart Scott’s motor expertise with Eaton’s industry knowledge – particularly in oil and gas, mining and manufacturing applications.

“The Hydre-MAC motor provides efficient, reliable and serviceable power at a low cost of ownership,” said Lyle Meyer, product manager at Eaton. “Additionally, Eaton’s global network of distributors with product and technology expertise and system design capability have the resources to quickly meet market demand to ensure critical operations are running optimally at all times.”

The motor increases component life with two inlet and outlet ports reducing pressure drops at high power, by generating less heat overall and through a symmetrical 18 piston/roller assembly design, which eliminates piston side-loading and reduces wear and tear.

To help customers maximise uptime, the Hydre-MAC motor is a direct drop-in replacement for the industry’s most installed motor, reducing switching costs by eliminating the need to replace the machine shaft and torque arm.

Longer component life extends motor life, which not only increases uptime, but reduces the total lifetime cost of ownership. Hydre-MAC’s repairable wear surfaces, including shaft seals, wear rings, piston seals and bearing pads, can be replaced on-site.

%$Linker: