Dynapac and Leica Geosystems are launching automated steering and screed edge control for asphalt pavers.

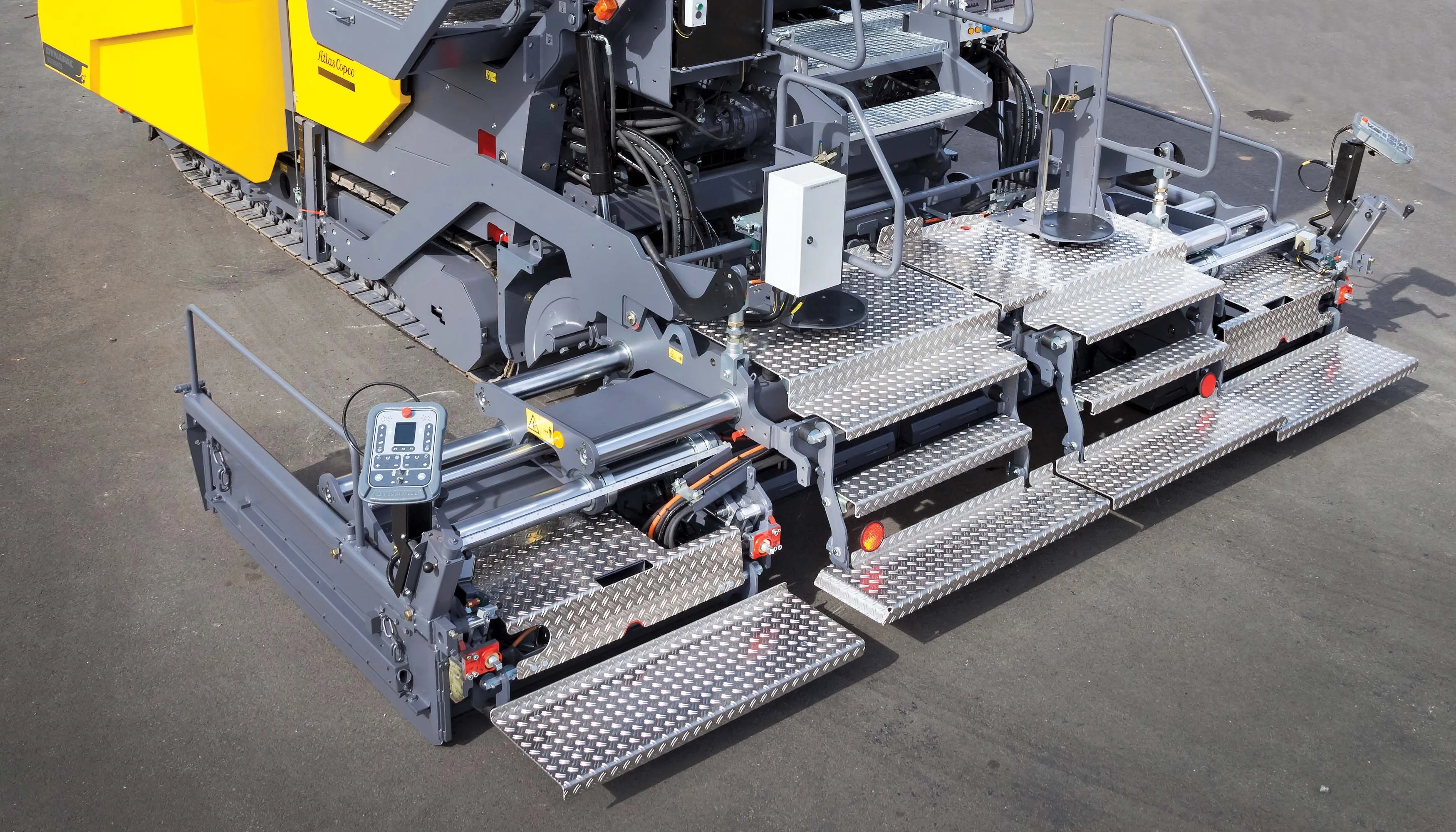

Together, the two firms are introducing a new integrated interface for auto-steering and screed edge control system for the SD25 and XD25 Highway Paver series.

The auto-steering and screed edge control features are being enabled on Dynapac asphalt pavers with the Leica iCON pave solution.

This partnership aims to enhance the precision and efficiency of asphalt paving operations by combining pavers from Dynapac with the machine control technology from Leica Geosystems.

In addition, the integration of new auto-steering and edge control features will enable pavers to follow stringline design models with millimetre accuracy, eliminating the need for traditional string-and-pins methods and reducing costs, while improving productivity.

With the Leica iCON pave machine control system, operators benefit from automated guidance and precise screed width adjustments based on a digital stringing design.

The system enhances site sustainability by optimising material usage, minimising waste, and ensuring more accurate material estimation.