At a diameter of less than 10µm, it can be inhaled. But if it is even smaller, below 2.5µm, this fine particulate can seriously damage lungs.

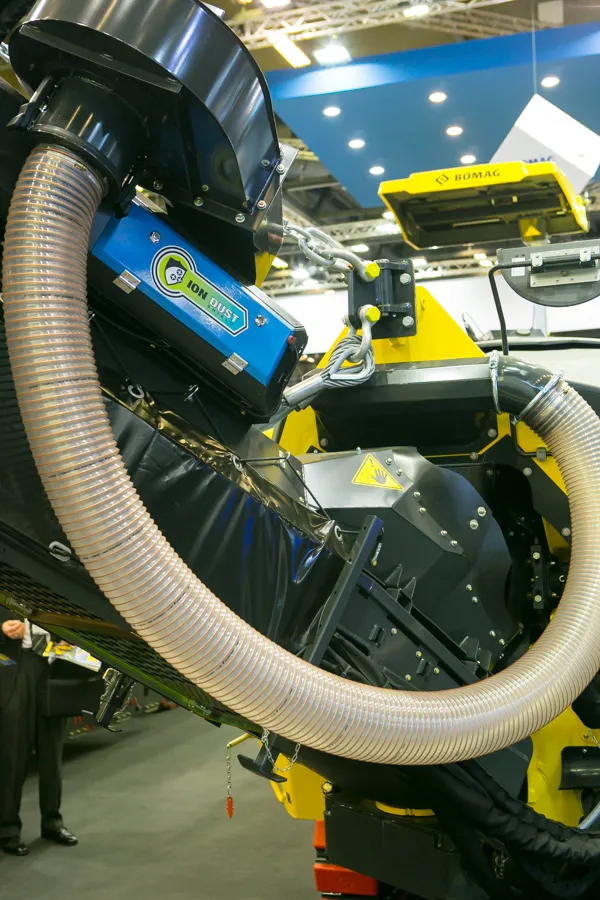

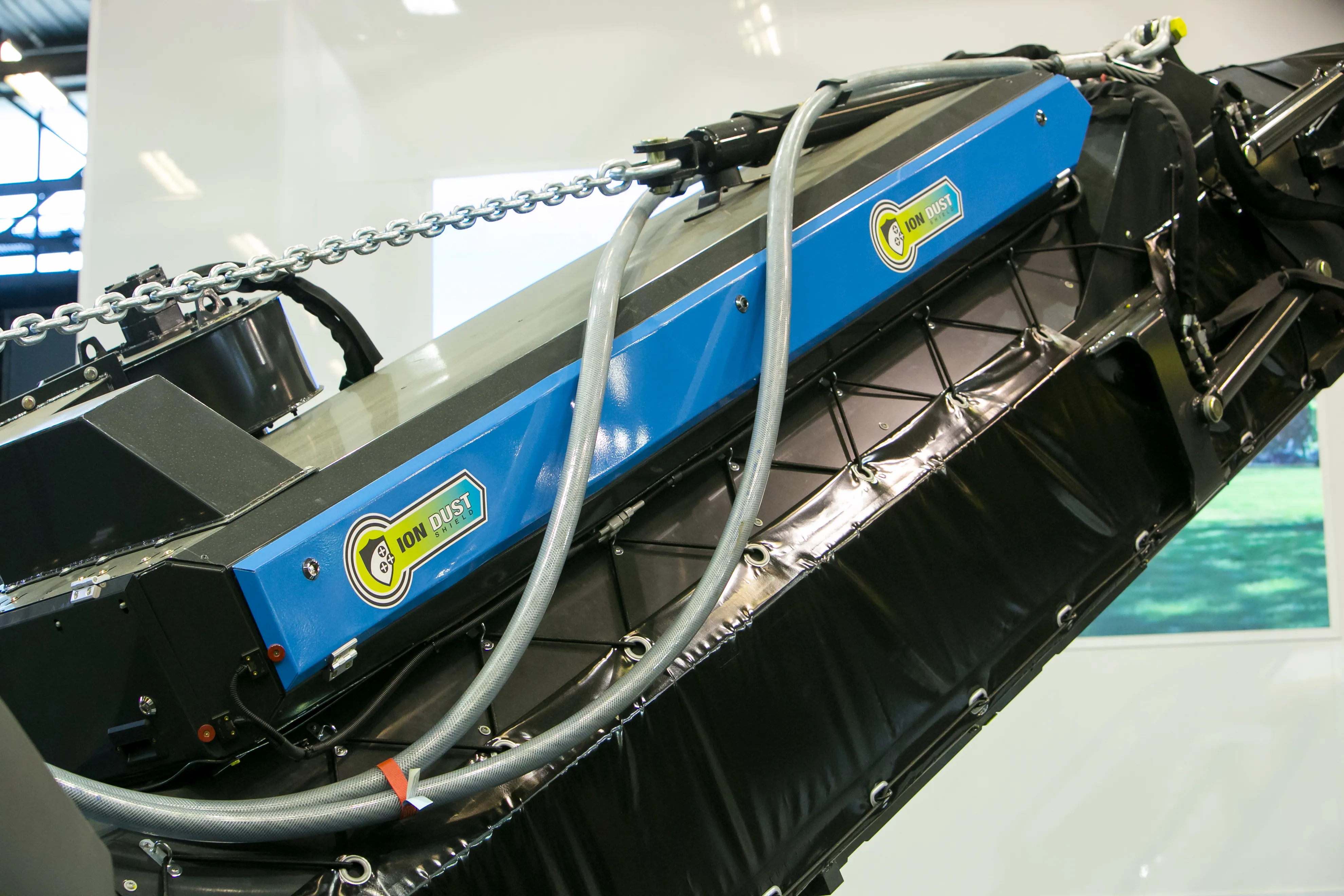

To render it harmless, Bomag’s Dust Shield - which sits neatly along and atop the planer’s conveyor unit - converts the fine particulate into larger-diameter matter, called flakes. This flocculated matter is less dangerous and easily deposited back on the conveyor for harmless disposal with the rest of the milled material.

The particulate matter is transported through an electric field where it becomes ionised and, now that it is positively charged, is attracted to a negative housing where it collects into larger matter.

Bomag says the efficiency of the Ion Dust Shield has been confirmed by the Institute for Hazardous Materials Research at Ruhr University in Bochum, Germany. More than 80% of fine particulates are bound electrostatically and rendered harmless.