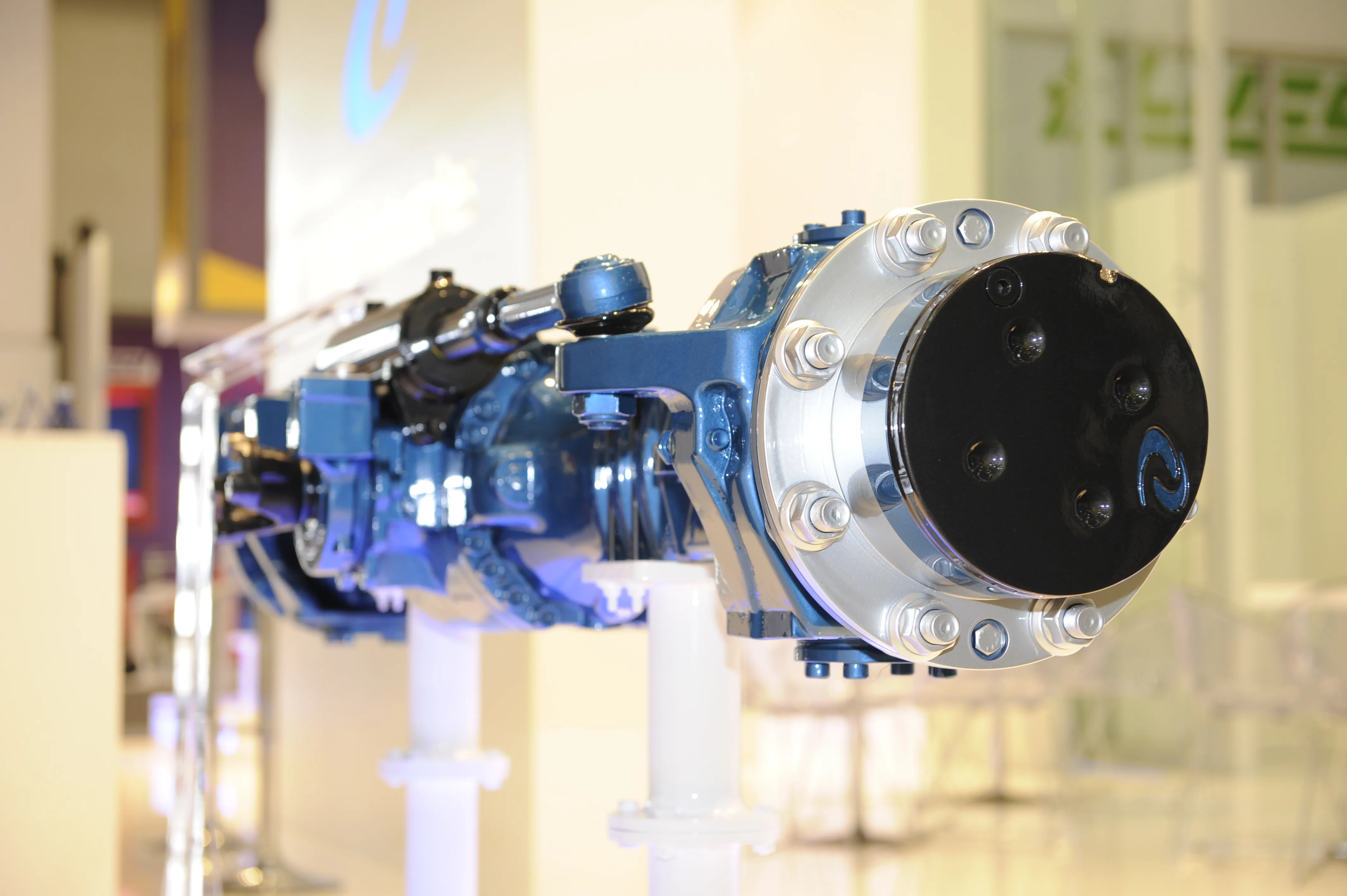

Driveline specialist Dana is developing a full connectivity suite for its transmissions, axles and other driveline components. The Dana Spicer Smart Suite collects, manages, analyses, communicates and acts on data from the complete drivetrain, including load and condition monitoring, torque management, speed sensing and steering sensing. This provides critical alerts and allows the operator to react to operational changes, boosting productivity and safety.

“As the construction market becomes more competiti

March 7, 2016

Read time: 2 mins

Driveline specialist 2254 Dana is developing a full connectivity suite for its transmissions, axles and other driveline components. The Dana Spicer Smart Suite collects, manages, analyses, communicates and acts on data from the complete drivetrain, including load and condition monitoring, torque management, speed sensing and steering sensing. This provides critical alerts and allows the operator to react to operational changes, boosting productivity and safety.

“As the construction market becomes more competitive, equipment manufacturers and owners are pressed to drive greater efficiencies,” said Aziz Aghili, president of Dana Off-Highway Driveline Technologies.

“Dana is actively developing a wide selection of leading edge technologies, led by Spicer Smart Suite technology, that can transform passive drivetrain components into intelligent powerful forces for boosting performance.”

The first application of the technology is an intelligent load monitoring system (ILMS) for telehandlers. While traditional load monitoring collects measurements from a single remote-mounted or retrofit load cell on the rear axle, Spicer ILMS uses data from across the machine to prevent tip-overs more effectively, both when stationary and when the machine is mobile.

All videos

“As the construction market becomes more competitive, equipment manufacturers and owners are pressed to drive greater efficiencies,” said Aziz Aghili, president of Dana Off-Highway Driveline Technologies.

“Dana is actively developing a wide selection of leading edge technologies, led by Spicer Smart Suite technology, that can transform passive drivetrain components into intelligent powerful forces for boosting performance.”

The first application of the technology is an intelligent load monitoring system (ILMS) for telehandlers. While traditional load monitoring collects measurements from a single remote-mounted or retrofit load cell on the rear axle, Spicer ILMS uses data from across the machine to prevent tip-overs more effectively, both when stationary and when the machine is mobile.

All videos