Ideal for quarry-based applications, the new Doosan 40-50 tonne DX420LC-5, DX490LC-5 and DX530LC-5 are the company’s largest Stage IV/Tier 4 Final compliant crawler excavators.

The operating weights of the DX420LC-5 and DX490LC-5 have increased by 700kg and 500kg respectively compared to the previous LC-3 models. Lifting capacities have increased by an average of 5% on all three models, except for the DX530LC-5, where the lifting capacity over the side has also increased by 12%.

February 4, 2015

Read time: 3 mins

Ideal for quarry-based applications, the new 695 Doosan 40-50 tonne DX420LC-5, DX490LC-5 and DX530LC-5 are the company’s largest Stage IV/Tier 4 Final compliant crawler excavators.

The operating weights of the DX420LC-5 and DX490LC-5 have increased by 700kg and 500kg respectively compared to the previous LC-3 models. Lifting capacities have increased by an average of 5% on all three models, except for the DX530LC-5, where the lifting capacity over the side has also increased by 12%.

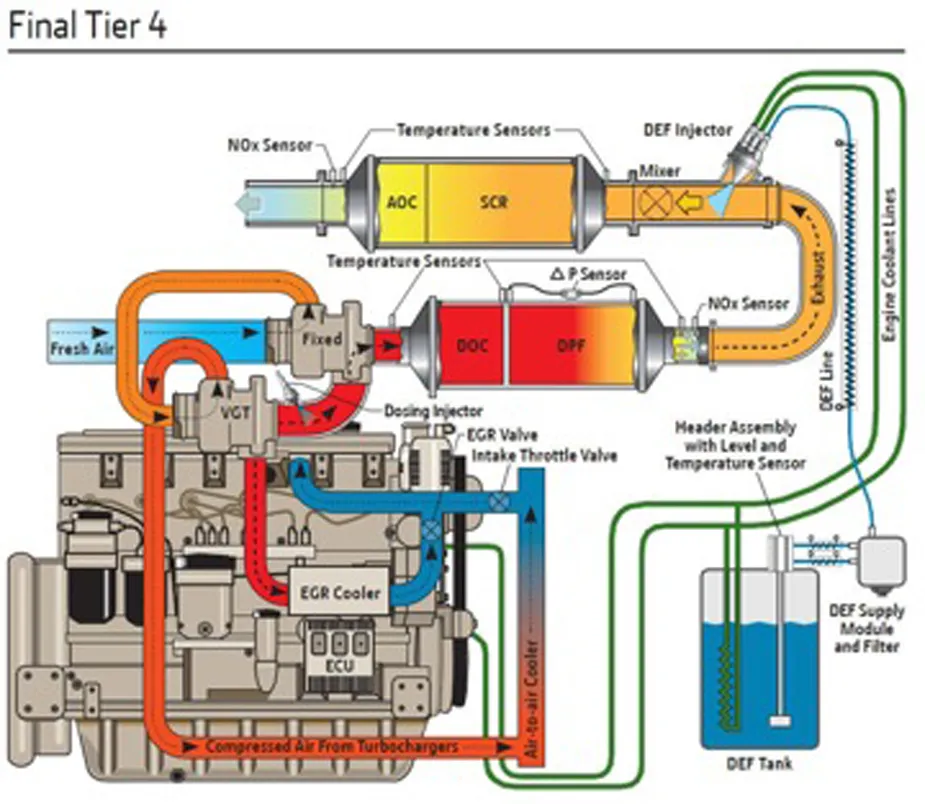

The new 42tonne DX420LC-5 is powered by the759 Scania DC13 diesel engine, providing 257kW of power at 1800rpm. The DX490LC-5 and DX530LC-5 are both powered by the Scania DC13 diesel engine, providing 283kW of power at 1800rpm. The engines meet Stage IV emission regulations without the need of a diesel particulate filter (DPF), through the use of cooled exhaust gas recirculation (EGR) and selective catalyst reduction (SCR) after-treatment technologies.

The new Scania engines in the DX420LC-5 to DX530LC-5 operate at a much lower engine speed of 1800rpm, down from 2000rpm in the Stage IIIB models, leading to significant reductions in fuel consumption, which factory tests are said to show to be an average of 5% across the three models. In addition, the move to the Scania DC13 diesel engine in the DX420LC-5 excavator has provided an increase in torque of 11%.

In addition to the fuel efficient Scania engines, new innovative and exclusive features have been introduced that together lead to reductions in fuel consumption amounting to a claimed average of 6% to 13% compared to the Stage IIIB machines.

A new ‘Trip Meter Setting’ screen allows operators to check fuel consumption daily (or over a desired period) directly from the control panel; the new Auto Shut-Off provides an automatic shut down for the engine after a pre-set time when the machine has been idling for a specified time (3 to 60 minutes configurable by the operator); and to save even more fuel, there is a special Doosan-developed system, Smart Power Control (SPC), to optimise the balance between the pumps’ output and the diesel engine.

The new cab in the DX420LC-5 to DX530LC-5 is said to have been further refined for outstanding operator comfort and ease of operation. This includes a new system that enables attachments to be operated from either the joystick or a two-way pedal. Users also have the novel Doosan excavator jog shuttle switch.

The operating weights of the DX420LC-5 and DX490LC-5 have increased by 700kg and 500kg respectively compared to the previous LC-3 models. Lifting capacities have increased by an average of 5% on all three models, except for the DX530LC-5, where the lifting capacity over the side has also increased by 12%.

The new 42tonne DX420LC-5 is powered by the

The new Scania engines in the DX420LC-5 to DX530LC-5 operate at a much lower engine speed of 1800rpm, down from 2000rpm in the Stage IIIB models, leading to significant reductions in fuel consumption, which factory tests are said to show to be an average of 5% across the three models. In addition, the move to the Scania DC13 diesel engine in the DX420LC-5 excavator has provided an increase in torque of 11%.

In addition to the fuel efficient Scania engines, new innovative and exclusive features have been introduced that together lead to reductions in fuel consumption amounting to a claimed average of 6% to 13% compared to the Stage IIIB machines.

A new ‘Trip Meter Setting’ screen allows operators to check fuel consumption daily (or over a desired period) directly from the control panel; the new Auto Shut-Off provides an automatic shut down for the engine after a pre-set time when the machine has been idling for a specified time (3 to 60 minutes configurable by the operator); and to save even more fuel, there is a special Doosan-developed system, Smart Power Control (SPC), to optimise the balance between the pumps’ output and the diesel engine.

The new cab in the DX420LC-5 to DX530LC-5 is said to have been further refined for outstanding operator comfort and ease of operation. This includes a new system that enables attachments to be operated from either the joystick or a two-way pedal. Users also have the novel Doosan excavator jog shuttle switch.