Driven by the most powerful engine in the 100tonne class, the DX1000LC-7 also has the highest hydraulic flow for this size of machine, according to the company.

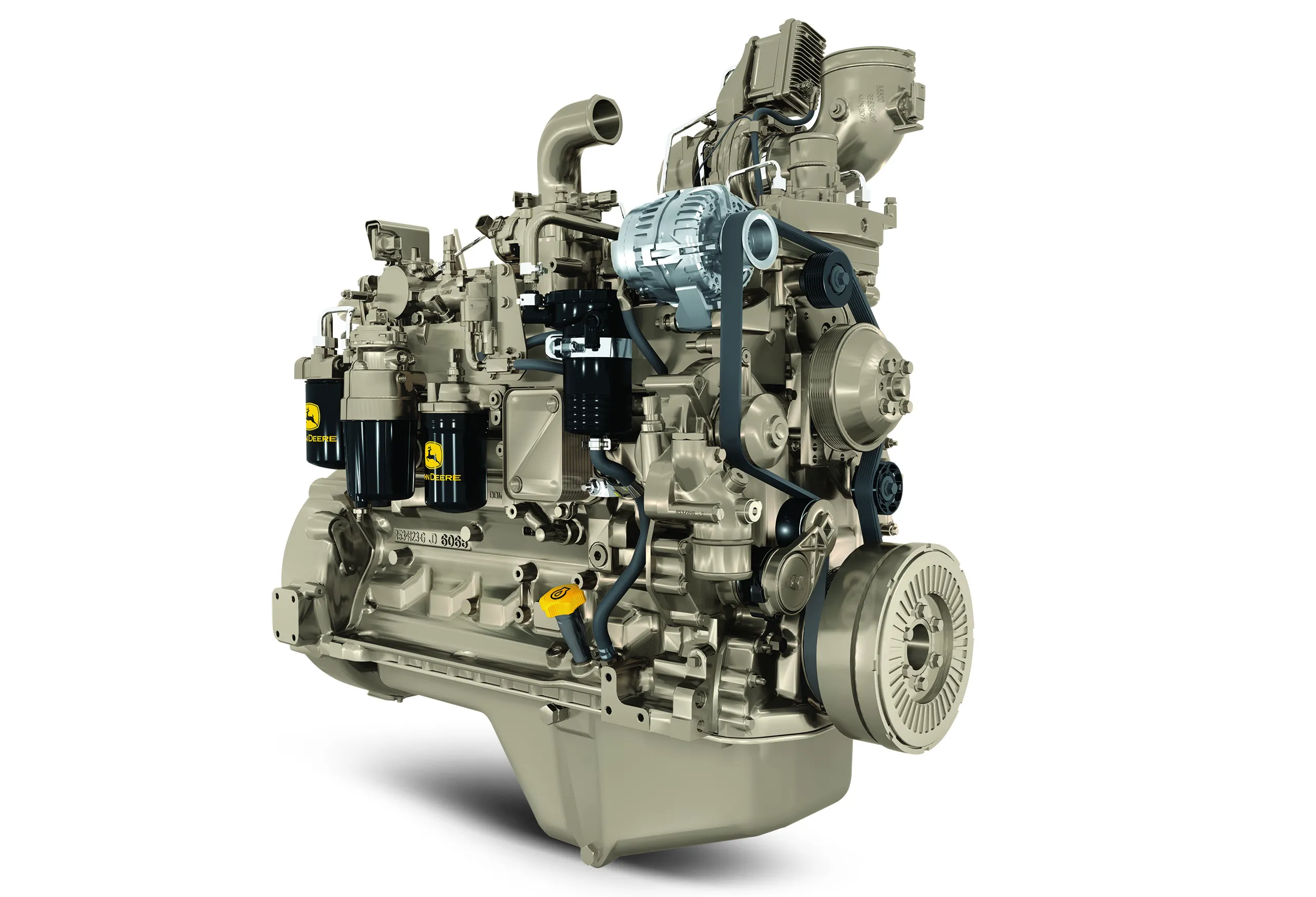

The DX1000LC-7 excavator is powered by the new stage V version of the well-proven Perkins 2806J diesel engine, providing a high power output of 469kW, more than any other machine in this class. The engine meets Stage V emissions regulations by using exhaust gas recirculation, selective catalyst reduction, diesel oxidation catalyst and diesel particulate filter (DPF) aftertreatment technologies.

The DPF automatically regenerates every 25 hours and the excavator continues to work unaffected during this regeneration phase. The operator can check the status of the DPF via the display on the gauge panel in the cab.

The high output of the engine is combined with a Virtual Bleed Off (VBO) hydraulic system (D-ECOPOWER+) and controlled by electric manipulator (FEH) providing a best-in-class hydraulic flow of (3 x 523) - 1569 litres/min and a high system pressure of 360 bar, together contribute to the best performance in the 100tonne market, says Dooosan.

Doosan’s D-ECOPOWER+ FEH technology uses an electronic pressure-controlled pump within a closed centre hydraulic system to optimise productivity and fuel consumption, depending on the mode selected. A closed centred main control valve minimises pressure loss, while the electric pressure-controlled pump manages and optimises engine power more effectively.

Faster working speeds are ensured by the two-spool Boom Down Regeneration system which also reduces fuel consumption. The two-spool system for the bucket cylinder also increases hydraulic flow and the working speed of the bucket, again reducing fuel consumption. The DX1000LC-7 also has a boom/arm cylinder lock valve (anti-hose burst valve) as standard for increased safety, preventing accidents caused by hydraulic hose rupture onsite.