Doka is inviting Conexpo 2014 visitors to take a look into the future of formwork technology – with the Austrian firm’s DokaTruss table and Super Climber SCP on show. A modular forming machine optimised for highrise cores, Doka says the new and improved version of the proven Super Climber SCP has been “rigorously developed”. In combination with DokaTruss table, a system aimed for setting and stripping large slab formwork, high speed construction cycles can, says Doka, be achieved efficiently.

In the Comp

January 17, 2014

Read time: 2 mins

A modular forming machine optimised for highrise cores, Doka says the new and improved version of the proven Super Climber SCP has been “rigorously developed”. In combination with DokaTruss table, a system aimed for setting and stripping large slab formwork, high speed construction cycles can, says Doka, be achieved efficiently.

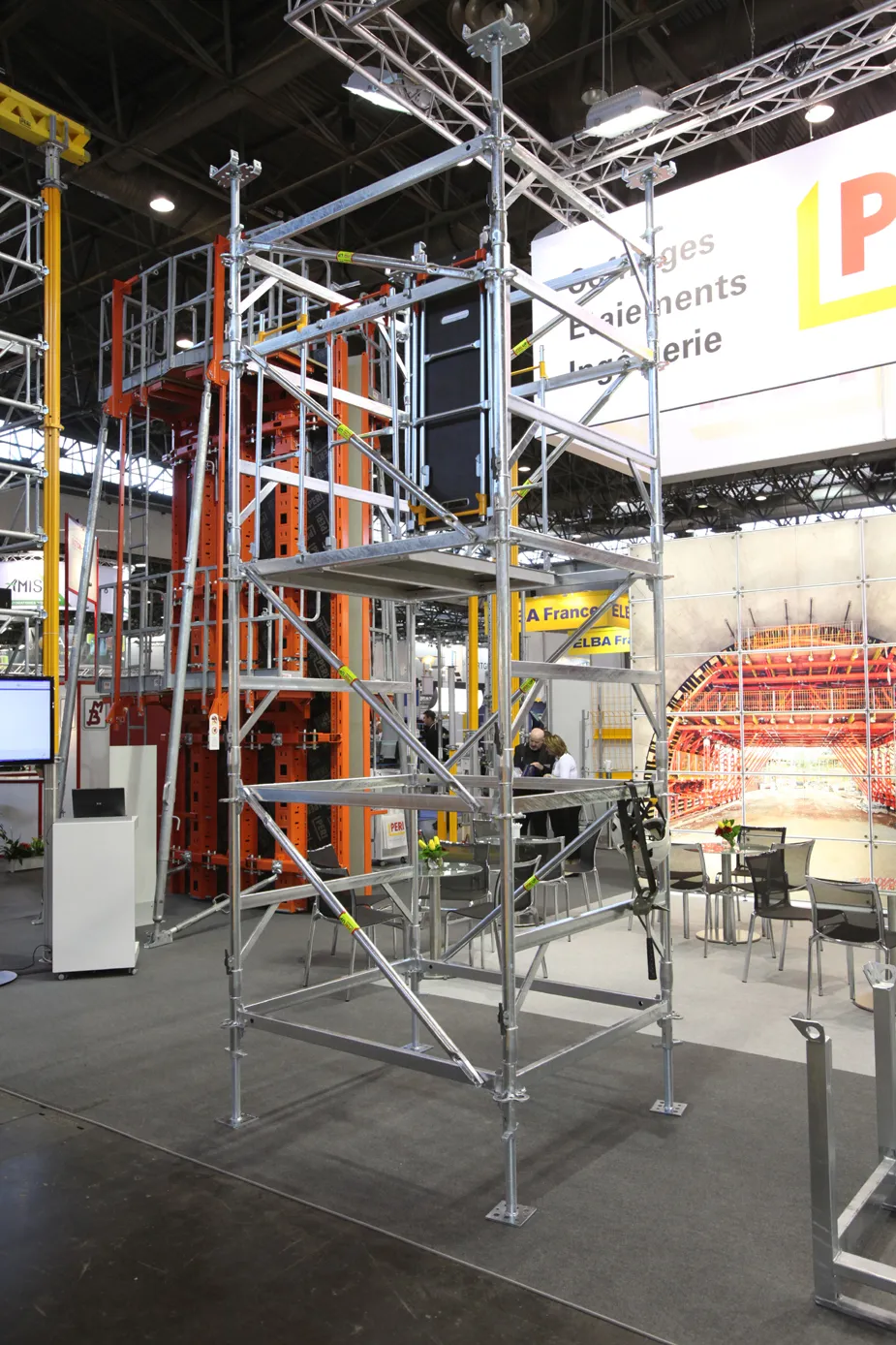

In the Component Corner of the Doka booth, visitors can get an insight into the company’s high quality standards and discover what the firm claims will soon be in heavy use on job sites around the world.

With projects like Tower 4 of the World Trade Center in New York, Colorado River Bridge in Texas or the Second Midtown Tunnel down the Elizabeth River in Virginia, Doka says it has demonstrated its expertise across the United States. In addition to its strong presence in the North American market, the company says its experience on construction projects worldwide has aided new product development and provides the basis for innovations – in both systems and services. “What Doka has to offer goes far beyond mere products. We work closely with our customers to devise individualised solutions for every construction project,” says Doka Group chairman Josef Kurzmann.

%$Linker: