Doka’s Concremote makes it possible to measure concrete strength on the site and in real time. It uses the weighted maturity method, as developed by de Vree, to provide reliable, standards-compliant information on the strength development of the concrete. This facilitates targeted management of the forming and CIP concreting operations.

The advantage of the method is the measurement take place directly in the concrete element. With well-placed sensors - thermos-couples - the temperature can easily be mea

March 3, 2016

Read time: 2 mins

The advantage of the method is the measurement take place directly in the concrete element. With well-placed sensors - thermos-couples - the temperature can easily be measured at any place on the construction. In addition, the continuous registration of the temperature at every point in time provides information on increase in weighted maturity and therefore directly on the development of the strength.

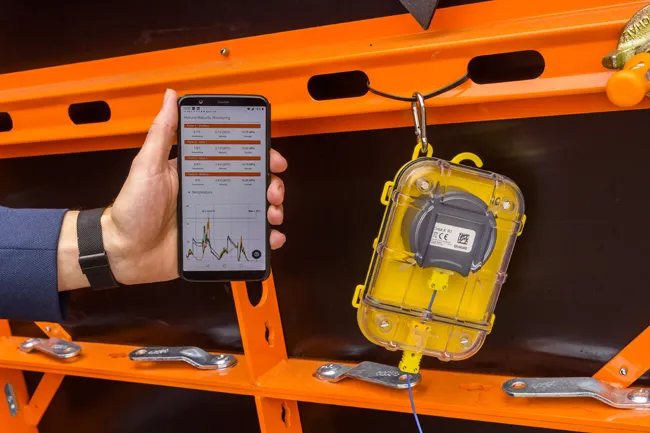

Concremote has two different types of sensor. The cableless slab sensor is used on Concrete in Place (CIP) concrete floor slabs, in cut-and-cover tunnel construction and at bridge-building sites. Cable sensors are particularly suitable for use on wall and column formwork and in crane-climbed and automatic climbing projects, at bridge- and tunnel-building sites and on mass concrete structures.

Cable sensors can be fitted with accessories that allow up to three different measuring points. The Concremote wall sensing element lets users integrate a measuring point into the formwork, permanently and re-useably. This makes it possible to reposition the sensors together with the formwork, without any extra work.

The Concremote sensors regularly measure the temperature development of the fresh concrete and transmit the data to the Concremote computing centre. Strength development of the concrete is calculated by reference to the values from the previously effected calibration measurement and the information is sent back to the site in real-time.

Once the fresh concrete has been struck off, the slab sensor can simply be placed in the concrete. The sensors' long battery life and rugged design mean that only minimal maintenance is needed.

The mobile web application lets users access the data on the strength development of their concrete at any time, from anywhere – on, for example, notebooks, tablets and smartphones.

Apart from Concremote, Doka is presenting its product enhancement Concremote plug.In. The systems integrated directly into the floor system to determines the correct stripping time.