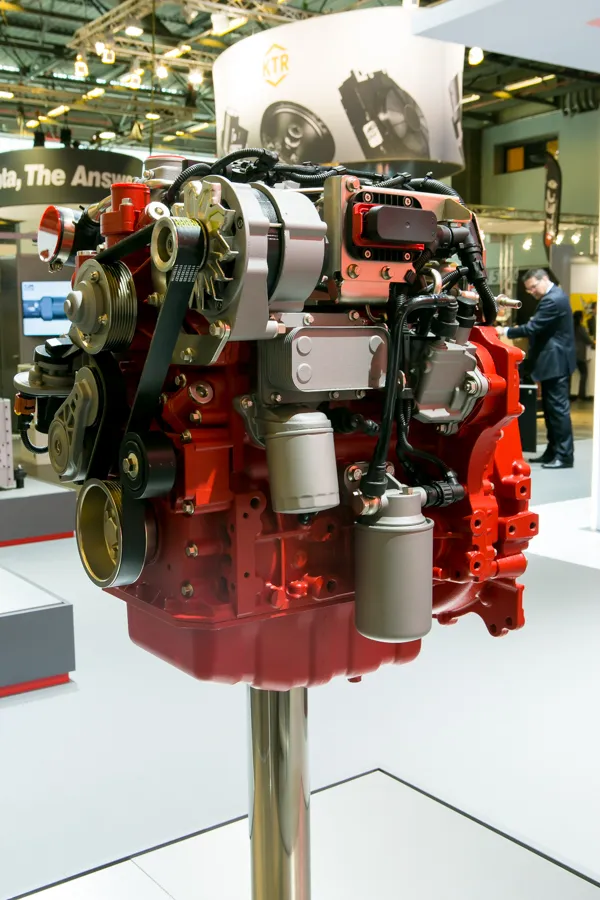

Deutz is to extend its lower powered engine line-up with an all-new three-cylinder unit based on the four-cylinder TCD2.9. Called the TCD2.2, this smaller engine will be rated from 22-56kW and will be available as a diesel-fuelled or LPG fuelled power unit, the latter badged G2.2. In addition, the larger TCD2.9 will also be available as an LPG engine and badged as the G2.9.

April 24, 2018

Read time: 1 min