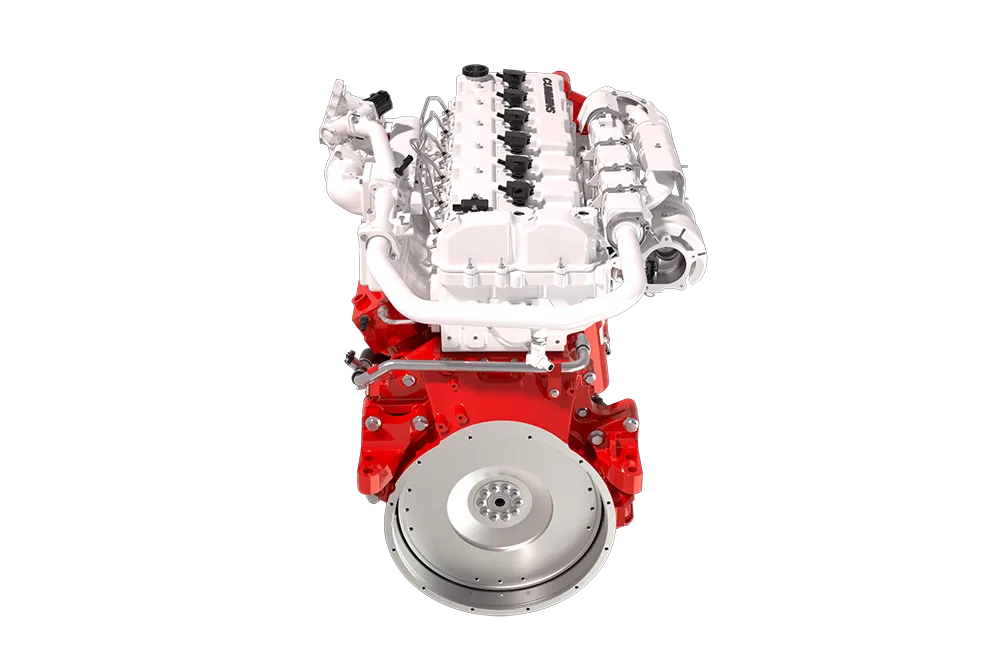

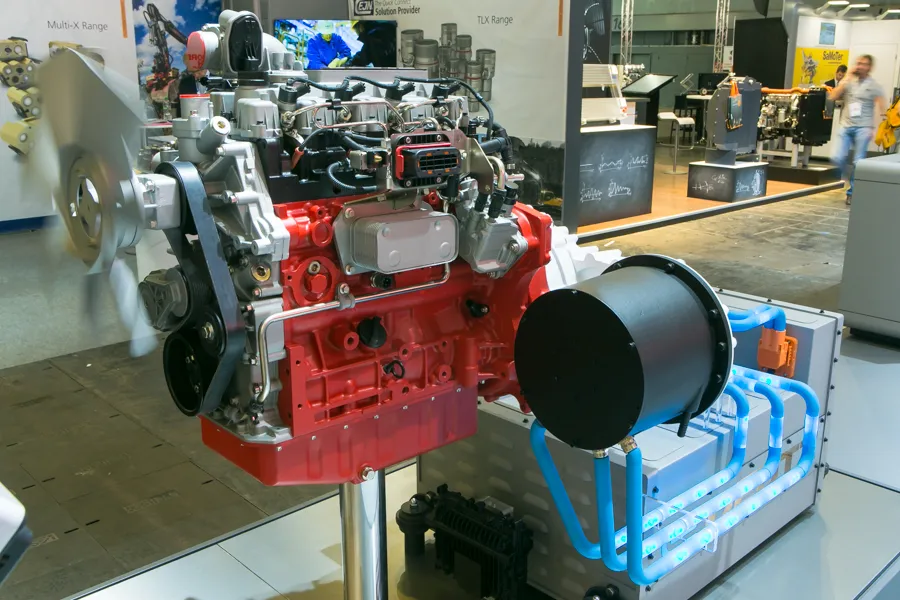

Called E-Deutz, the modular power unit combines a diesel engine, electric motor and battery pack, which forms the basis of a full range of electric drives and hybrid systems as the engine maker moves forward with its electrification strategy.

E-Deutz is currently available with a 110kW output, which combines 55kW from a 2.9 litre TCD2.9 stage V-compliant diesel engine with a 55kW electric motor with power electronics and a 44kWh battery pack.

“Such a hybrid powertrain can offer an electric boost function, it can provide 100% electrical power and it can use the diesel engine when necessary to recharge the battery pack,” explained Dr Frank Hiller, CEO of Deutz. “This technology has enabled us to develop an automatic start/stop function for the diesel engine, and it can offer an electric power take-off.”

The company said the system is scaleable, so the E-Deutz concept will eventually be applied to all engines in the portfolio from 19-620kW. “This will give our customers a lower total cost of ownership, reduced operating costs, lower fuel consumption and improved operating dynamics,” he said. “Tighter emissions regulations will force the adoption of vehicle electrification in on-road vehicles, and this will drive the development for off-road vehicles too.”

Hiller added that Deutz has already built a prototype telehandler operating with the E-Deutz power unit and the firm is also working on a fully-electric powertrain solution.

“We expect to be producing commercially available electric drive solutions within two years,” he concluded.