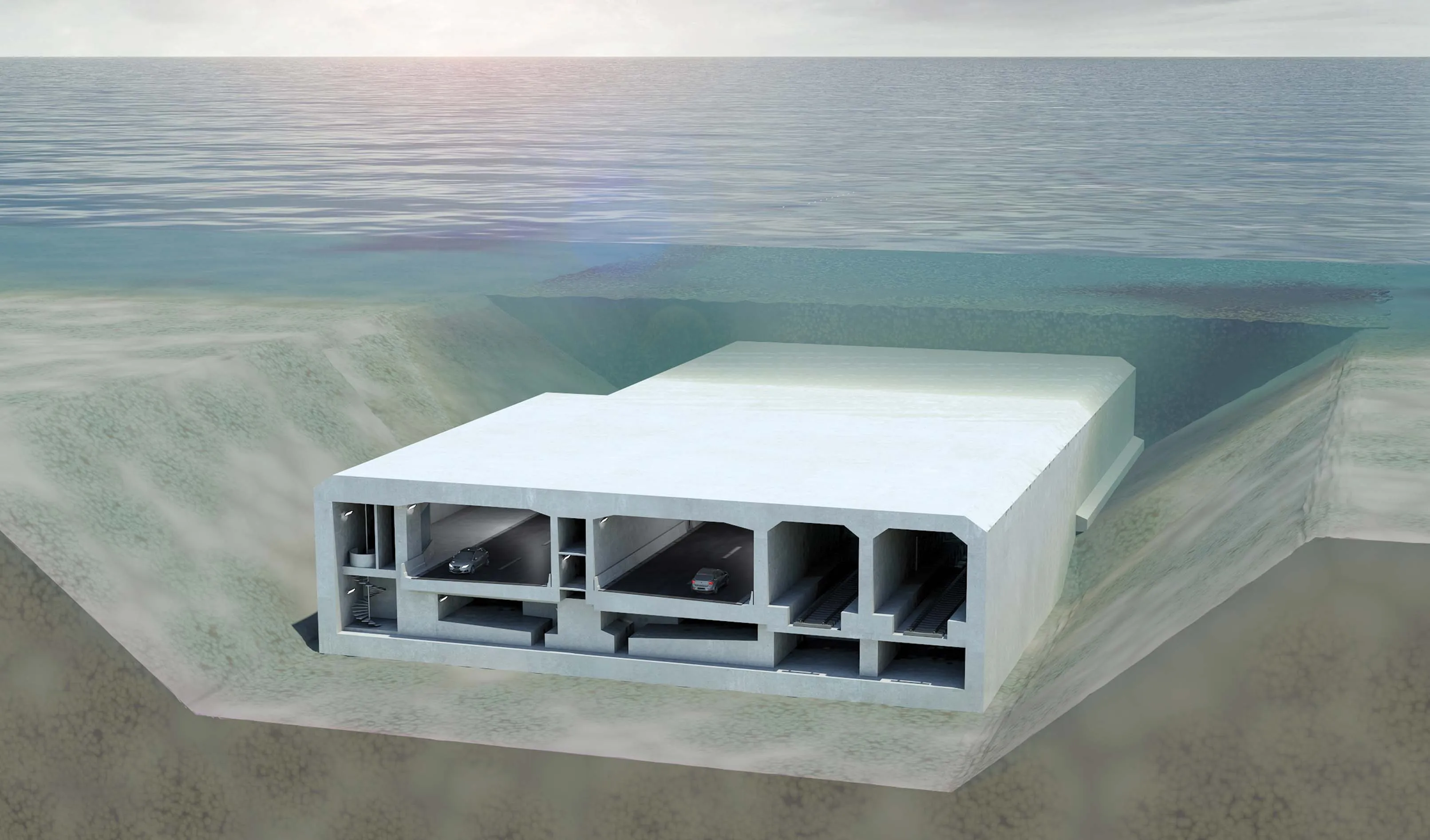

The e+s XL Carriage range allows a maximum working depth of 9m for jobs needing large-scale trenches such as concrete structures, rainwater retention basins, water collectors and deep pipe-laying projects.

The maximum width of the end-supported shoring system is now 18m.

ThyssenKrupp says that the system works well on sites where deeper work is required and there are no space restrictions, not least because of the crane assistance needed for the system members.

The carriage absorbs both compressive forces from the sides of the shoring as well as loads from the end face. Up to now, the forces have been transferred to separate components - the carriage and shoring struts.

The advantage is that only the carriage is needed and no other components are necessary, allowing faster and more efficient installation.

The second new product in the range is a large U-type carriage car. This is used for large shoring widths of 10m in trenches that can be 6m deep or more … or where there are high loading requirements.