Danfoss Power Solutions is introducing version 7.0 of PLUS+1 GUIDE, an industry-proven graphical programming environment. This is said to offer new features and options that increase developer productivity and support functional safety standard IEC 61508-3, version 7.0 of PLUS+1 GUIDE (Graphical User Integrated Development Environment). The firm says that this offers its customers lower development costs, easier machine certification and reduced time to market. New features and options include the capabilit

January 17, 2014

Read time: 2 mins

Version 7.0 of GUIDE enables developers to import and export entire screens and screen library subsets in the GUIDE screen editor, allowing much faster development of screens. Support of the scalable vector graphic (SVG) graphic data format permits automatic rescaling of available screens and easy reuse of available screens and graphics.

Porting screens to different display models, screen resolutions and screen sizes can be performed much faster with Plus+1 GUIDE 7.0. Content is stretched to fit the screen, and only minimal manual work is required as button positions and layout may vary.

The optional GUIDE-to-Simulink feature enables any GUIDE page to be exported with one click to a Simulink S-function for use in model-based development. This capability eliminates the need to rewrite and maintain code while ensuring that code is identical from one tool chain to the other.

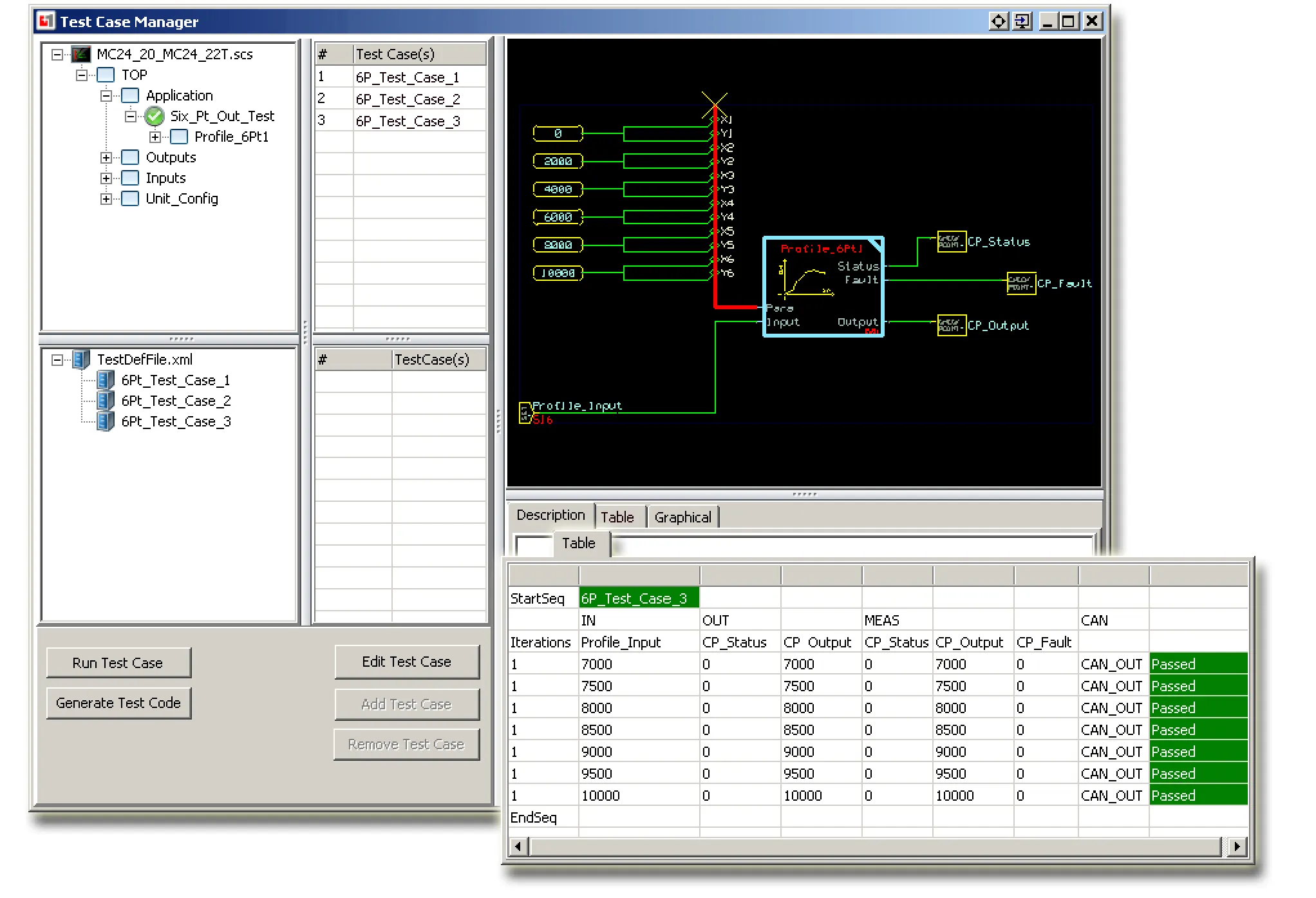

The optional quality assurance tool contains the GUIDE test tool, a comparison of graphical code feature and version control tools. Available as one package, these features save time and cost during development and the creation of documentation required for certification.

Also available is an optional beta quality assurance tool including debugger and dependency tools. Capable of stepping from one component to the next and displaying data values, the debug tool is a user-friendly feature that saves time during testing and error tracing. The GUIDE dependency view provides a graphical indication of project code that is impacted by code changes, enabling retesting to be limited to affected functions.

Version 7.0 of Plus+1 GUIDE will be released for Windows 8 in addition to Windows XP and Windows 7.

%$Linker: