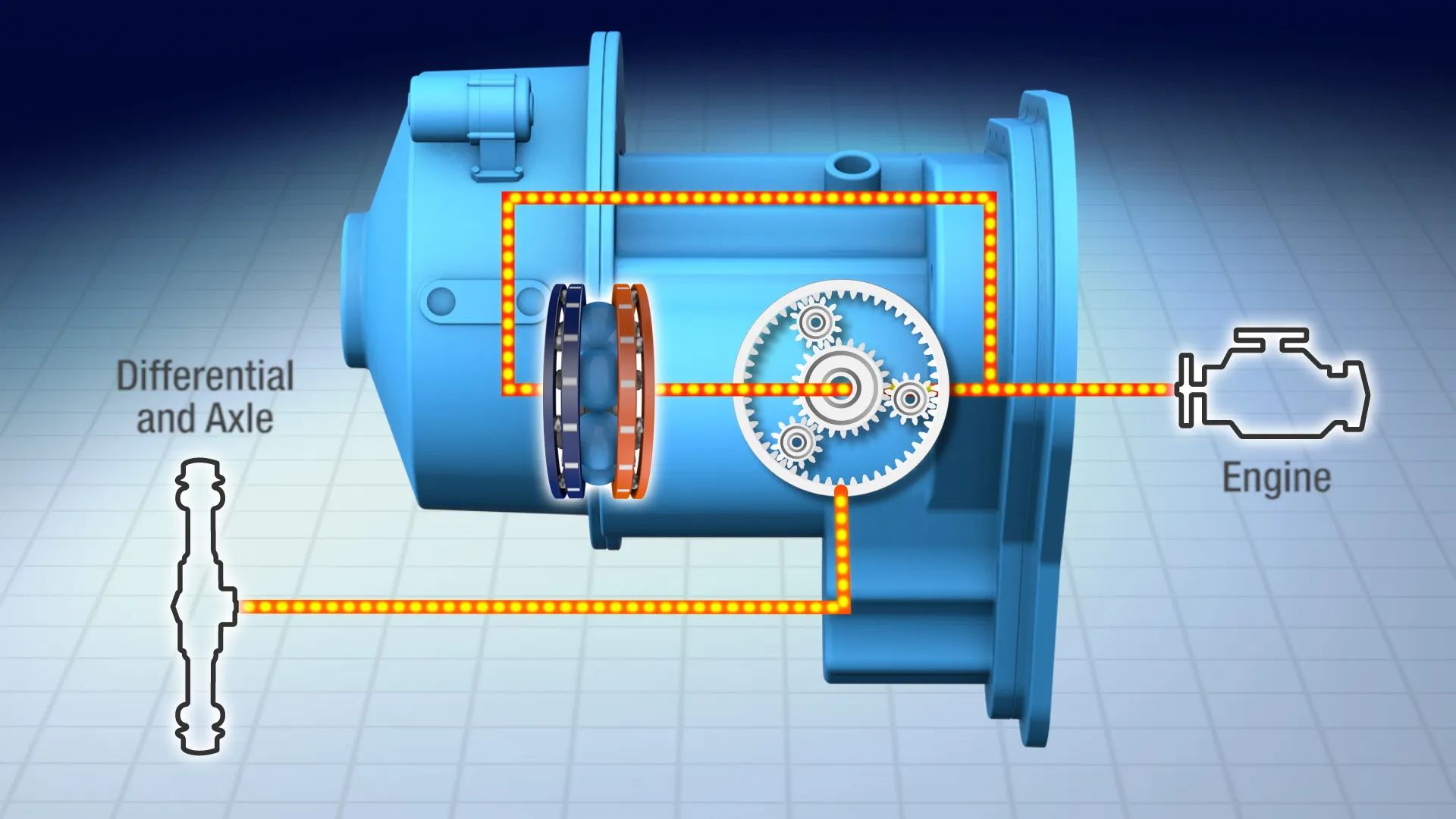

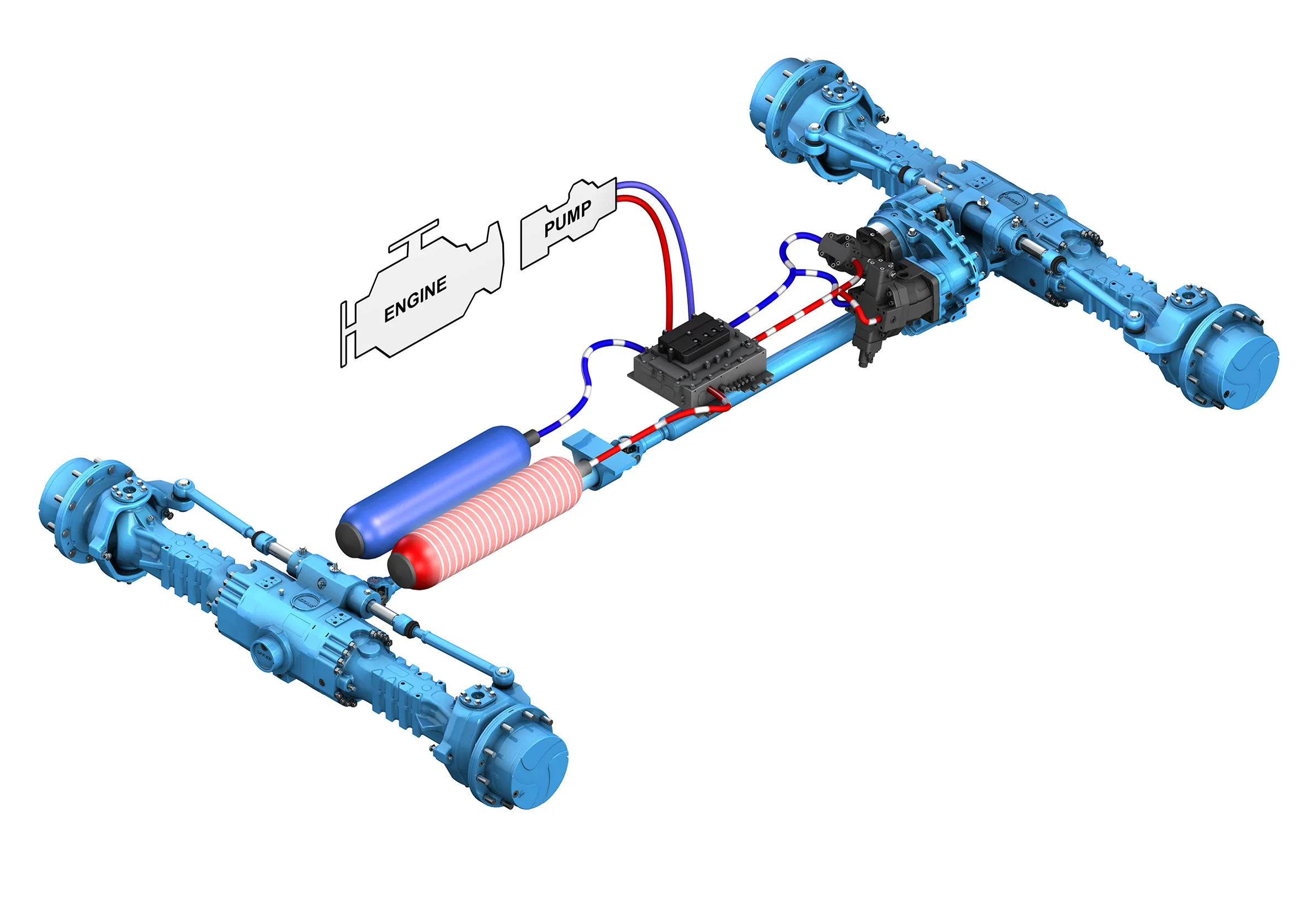

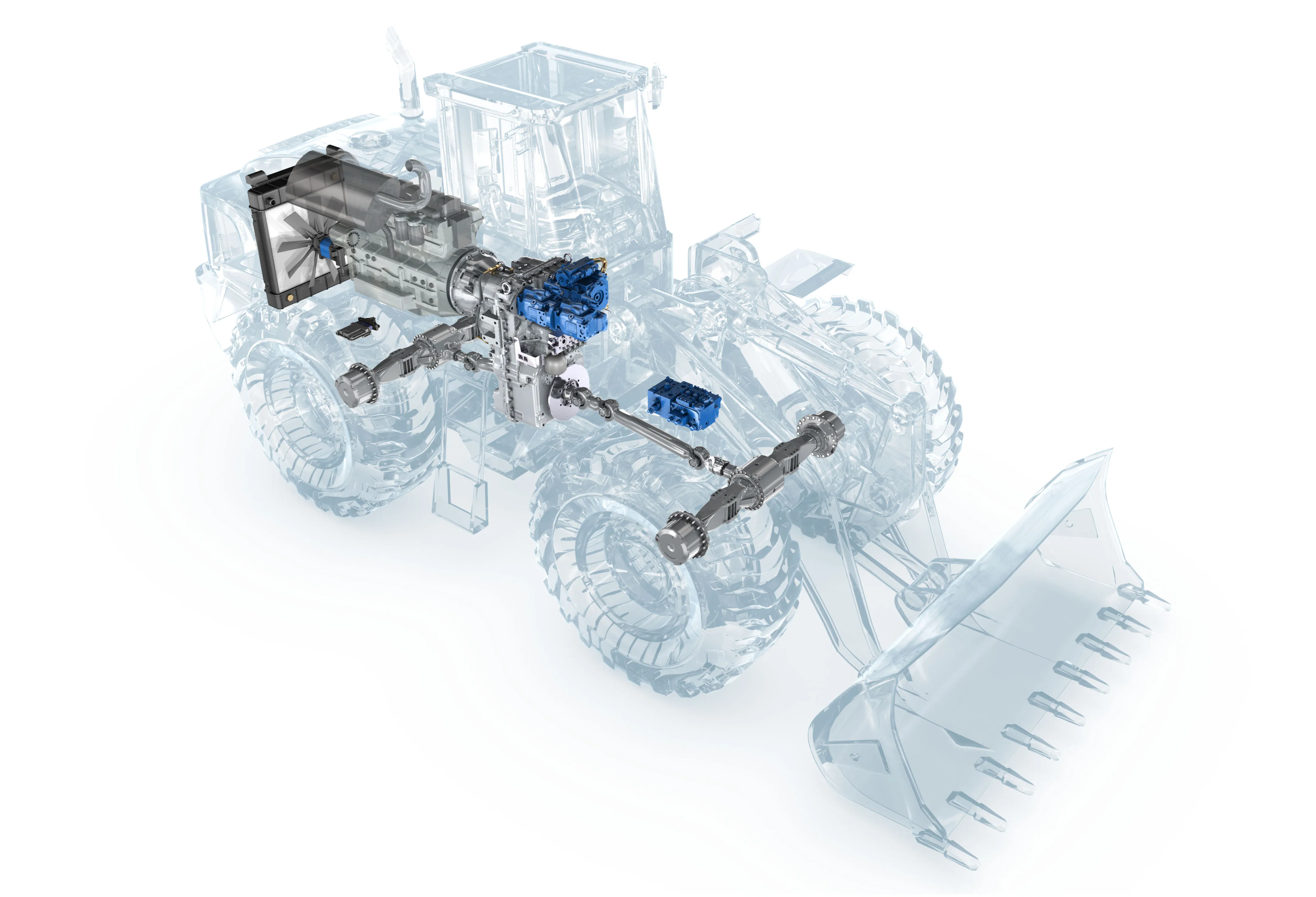

Dana Rexroth’s R2 hydromechanical variable transmission, the HVT R2, is close to being introduced to the market.

The company, a joint venture between Dana Holding Corporation and Bosch Rexroth, says engineers have completed final validation testing of the system, with production expected to start in the third-quarter of 2015.

January 30, 2015

Read time: 1 min

The company, a joint venture between Dana Holding Corporation and

Field tests on working vehicles are said to have shown fuel savings of up to 25% over traditional transmission designs.

“The HVT R2 has shown the value of power split technology at every stage of development, both in fuel economy and in application performance,” says Diego Cornolti, head of sales and product management for Dana Rexroth Transmission Systems.

“We have confirmed these gains through extensive testing on multiple off-highway applications, and we are collaborating with several original equipment manufacturers to deliver HVT technology on market vehicles later this year.”