Consistent with its approach in other vehicle markets, Dana’s strategy enables original equipment manufacturers (OEMs) to accelerate their hybrid and electric vehicle development programmes. It starts with a modular approach that combines Spicer electrified hybrid and electric drivetrain solutions into current vehicle architectures with internal-combustion engines.

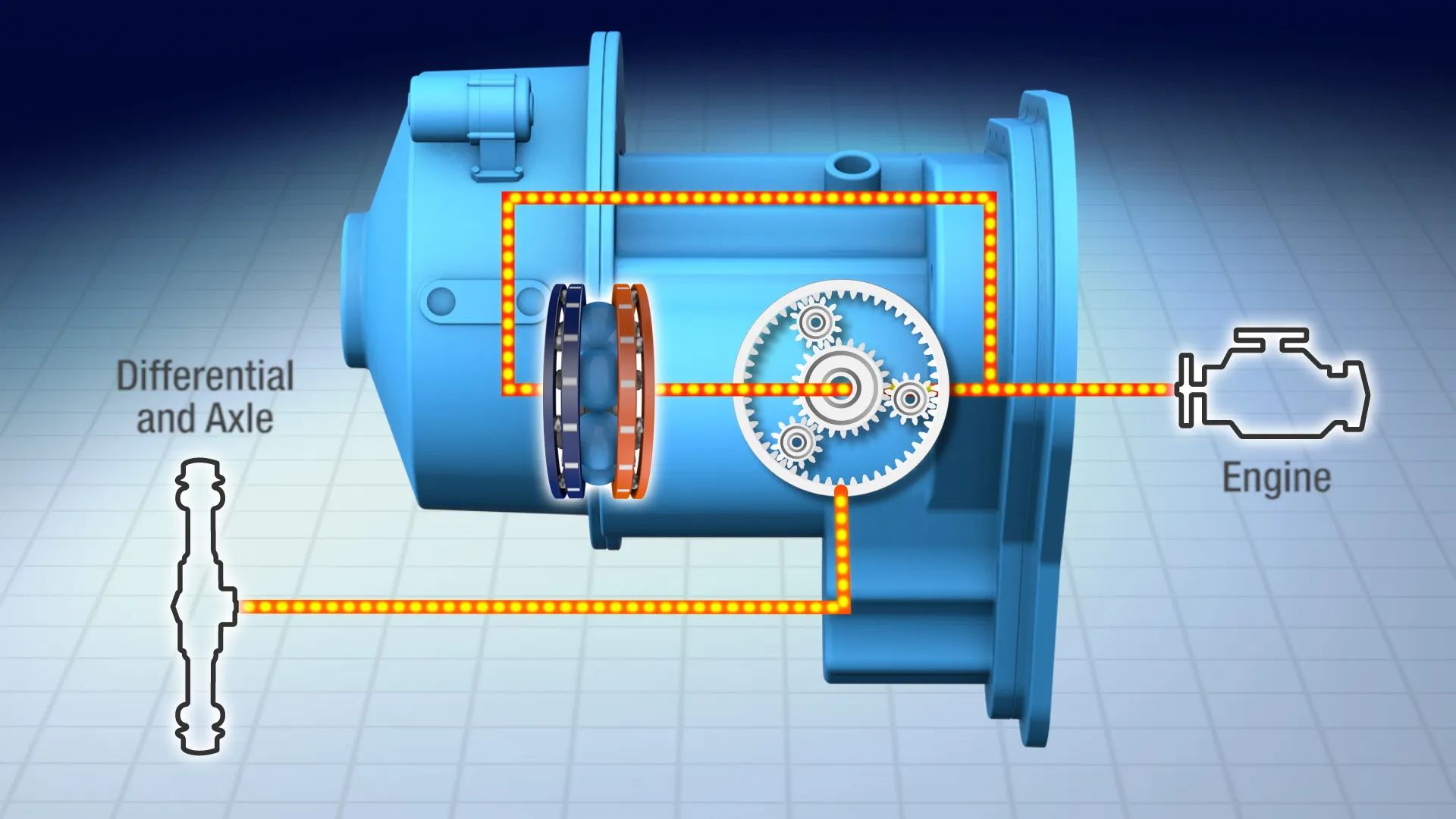

Dana offers a series of modular hybrid- and electric-drive systems that can fit into existing vehicle designs and provide OEMs with effective, low-risk, quick-to-market solutions. These products can be connected to traditional Spicer wheel drives, track drives, axles, and transmissions to deliver hybrid or electric functionality.

In addition, Dana is also actively developing hybrid and electric drive solutions for numerous wheeled and tracked vehicles in the construction, mining and material-handling industries.