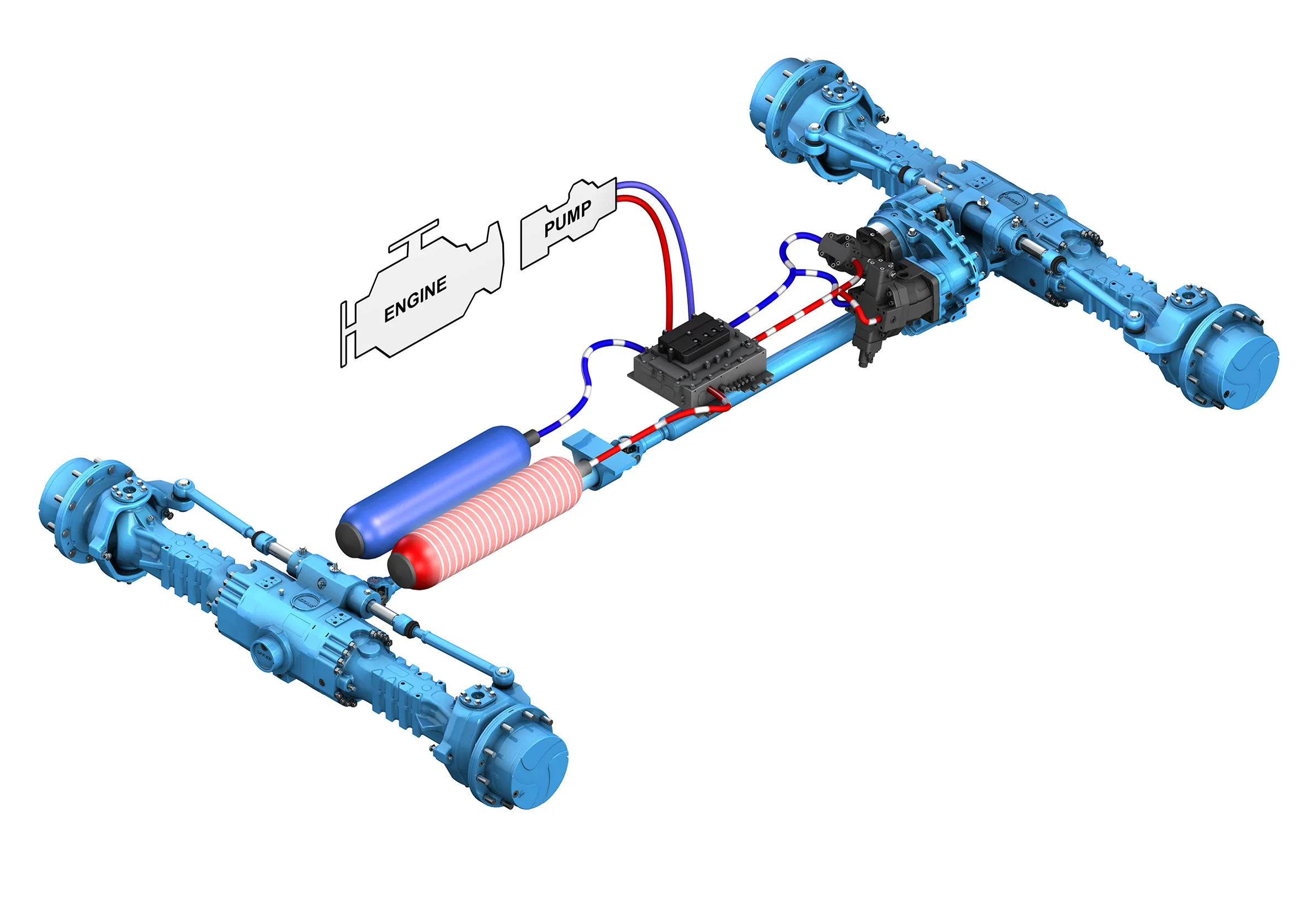

Dana Holding Corporation is now offering its Spicer PowerBoost hydraulic-hybrid system for field testing by off-highway original-equipment manufacturers (OEMs).

The Spicer PowerBoost concept will feature as part of a complete drivetrain system for a compact telescopic boom handler with 2.7-3.6tonne lifting capacity.

January 28, 2015

Read time: 2 mins

The Spicer PowerBoost concept will feature as part of a complete drivetrain system for a compact telescopic boom handler with 2.7-3.6tonne lifting capacity.

The Spicer PowerBoost system works by capturing hydrostatic energy in an accumulator from the powertrain during low-power operation of the engine and when recuperated from braking.

Dana says that deployed through series or parallel hybrid configurations that fit into existing vehicle designs with minimal adaptation, the Spicer PowerBoost system supplements all types of transmission architectures.

It captures kinetic energy otherwise wasted throughout the drivetrain and working hydraulics and then uses this recuperated energy to help power the vehicle, and the company claims this can reduce fuel consumption by 20-40% compared with conventional drivetrain concepts, depending on vocational application and duty cycle.

“Despite the recent downturn in diesel prices, off-highway equipment buyers are still actively pursuing technologies that can reduce overall vehicle operating expenses,” says Aziz Aghili, president of Dana Off-Highway Driveline Technologies.

Dana has supported the development of the Spicer PowerBoost system over the past five years at the company’s advanced technology centres in Belgium, Italy, and the United States.