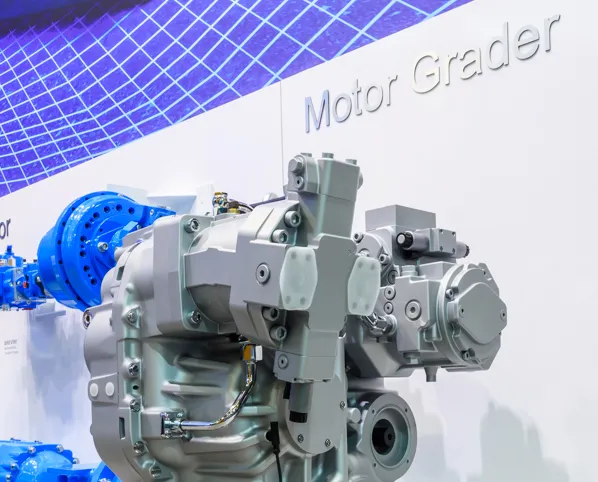

Dana Rexroth transmission systems says it is working with engine manufacturers in the off-highway industry to support European stage V engine emissions regulations.

Its hydromechanical variable transmission (HVT) platform is already prepared for stage V emissions standards, and the firm is collaborating with leading engine manufacturers to develop transmission control software that will allow it to deliver a fully compliant solution.

April 23, 2018

Read time: 1 min

Its hydromechanical variable transmission (HVT) platform is already prepared for stage V emissions standards, and the firm is collaborating with leading engine manufacturers to develop transmission control software that will allow it to deliver a fully compliant solution.

HVT is the result of a joint venture between

Application analysis has demonstrated the possibility of further fuel savings without compromising performance through engine downsizing.