A dimensionally accurate replica of the famous Napier Railton race car which created a sensation during the 1930s with a series of record-breaking achievements will be shown by Cummins.

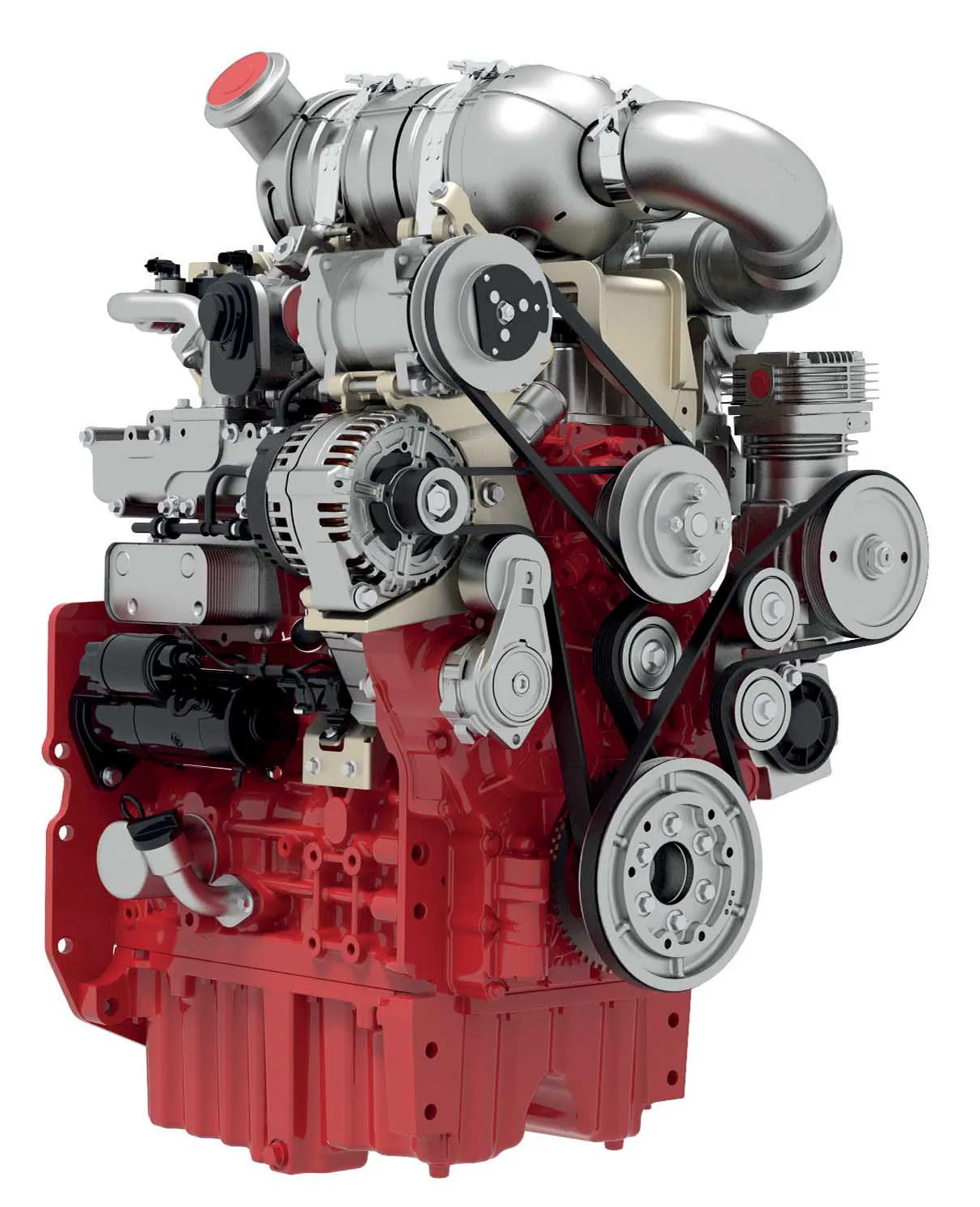

The Cummins Napier Railton, to be seen alongside the line-up of latest engine technology, is powered by a Cummins 6.7litre diesel, the same base engine widely used in many types of construction equipment, including excavators and wheeled loaders.

While the latest QSB6.7 engine meeting Tier 4 Final/Stage IV emissions r

January 6, 2017

Read time: 2 mins

A dimensionally accurate replica of the famous Napier Railton race car which created a sensation during the 1930s with a series of record-breaking achievements will be shown by 196 Cummins.

The Cummins Napier Railton, to be seen alongside the line-up of latest engine technology, is powered by a Cummins 6.7litre diesel, the same base engine widely used in many types of construction equipment, including excavators and wheeled loaders.

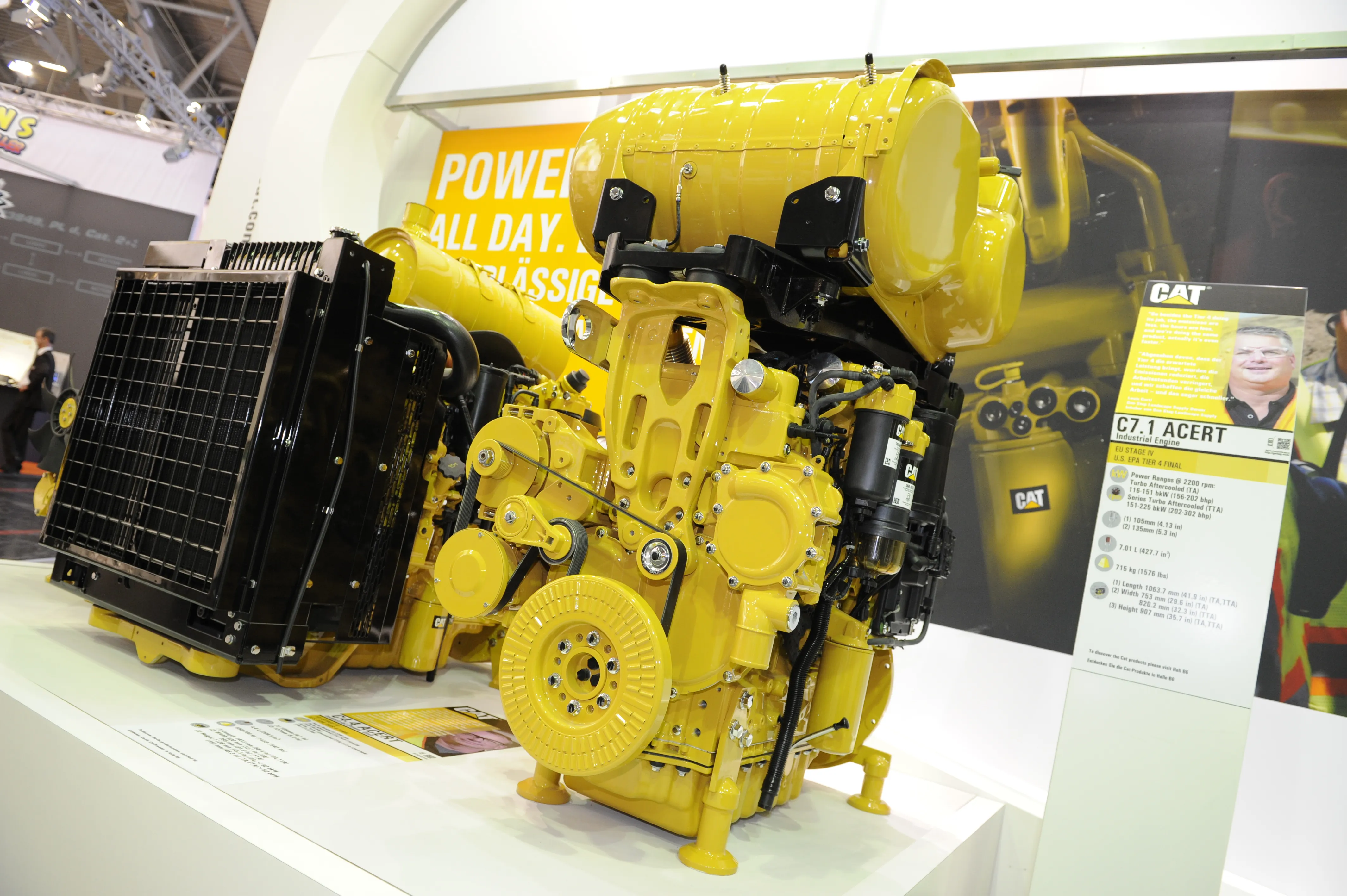

While the latest QSB6.7 engine meeting Tier 4 Final/Stage IV emissions regulations offers a top rating of 224kW, the Cummins engineers have achieved close to 373kW output for the diesel installed in the Railton replica.

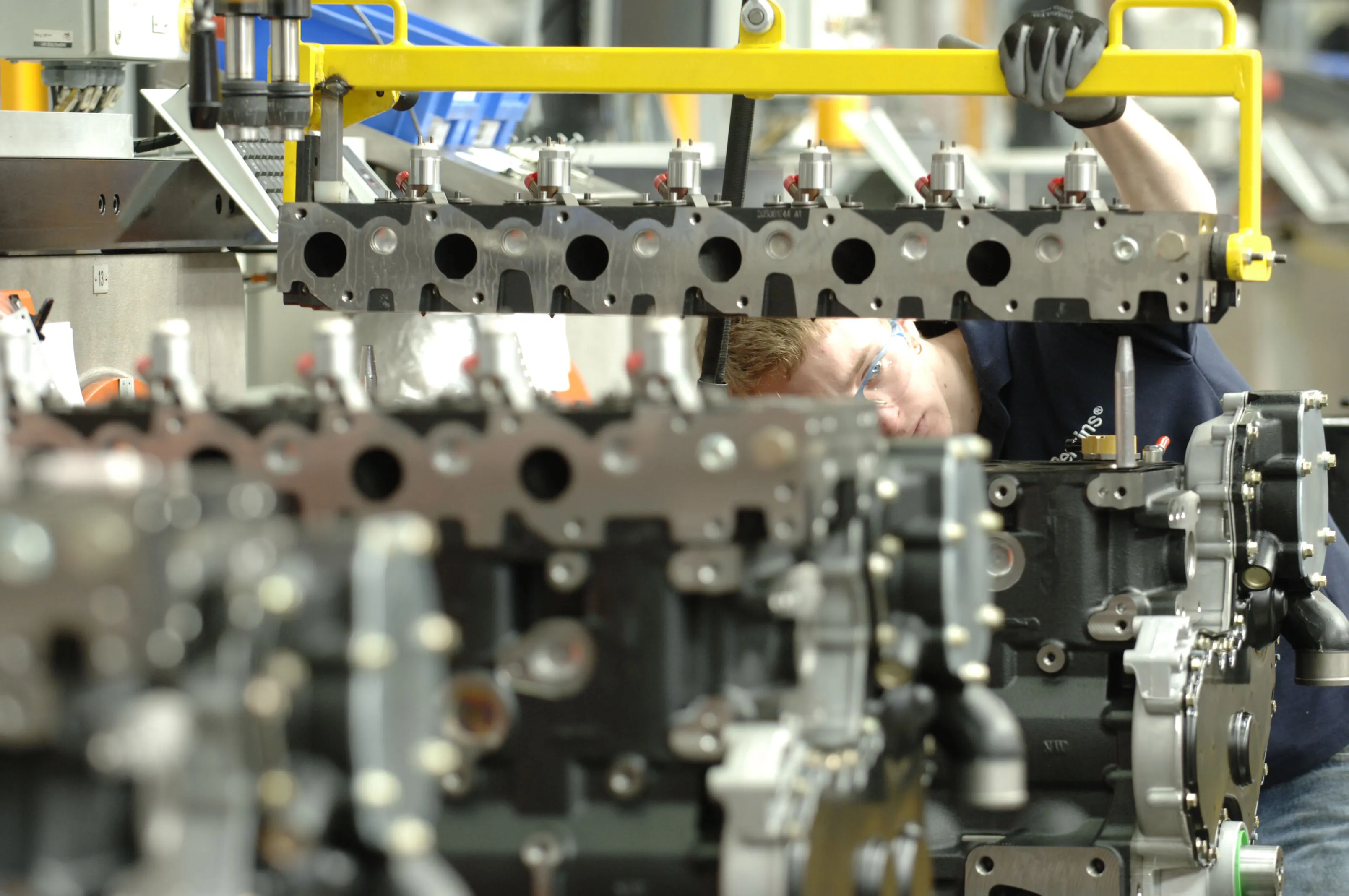

The replica was created by British engineer Terry Clarke, working closely with engineers located at the Cummins Darlington engine plant in the UK.

The original Railton car, now based in the Brooklands Museum, County Surrey, southern England, is powered by a Napier Lion XI gasoline 12-cylinder aero engine, with 24litres and a rated power of 395kW.

It was first raced in August 1933 by John Cobb and broke the Brooklands outer circuit lap record of 143.4mph in 1935. The racer went on to set the 24-hour record of 150.6mph at the Bonneville Salt Flats, USA, in 1936.

The Cummins Napier Railton, to be seen alongside the line-up of latest engine technology, is powered by a Cummins 6.7litre diesel, the same base engine widely used in many types of construction equipment, including excavators and wheeled loaders.

While the latest QSB6.7 engine meeting Tier 4 Final/Stage IV emissions regulations offers a top rating of 224kW, the Cummins engineers have achieved close to 373kW output for the diesel installed in the Railton replica.

The replica was created by British engineer Terry Clarke, working closely with engineers located at the Cummins Darlington engine plant in the UK.

The original Railton car, now based in the Brooklands Museum, County Surrey, southern England, is powered by a Napier Lion XI gasoline 12-cylinder aero engine, with 24litres and a rated power of 395kW.

It was first raced in August 1933 by John Cobb and broke the Brooklands outer circuit lap record of 143.4mph in 1935. The racer went on to set the 24-hour record of 150.6mph at the Bonneville Salt Flats, USA, in 1936.