Cummins Emissions Solutions, the engine manufacturer’s specialist after-treatment division, has developed a single-unit DPF-SCR module concept that is 60% smaller and 40% lighter than its current two-box solution. The EcoFit single module has been designed to work with Cummins’ Stage V engines when they arrive in 2019. “We could achieve Stage V with our current DPF-SCR system, however Stage V is an opportunity to take this technology further,” said Richard Payne, Cummins’ off-highway regulatory affairs dire

January 6, 2017

Read time: 2 mins

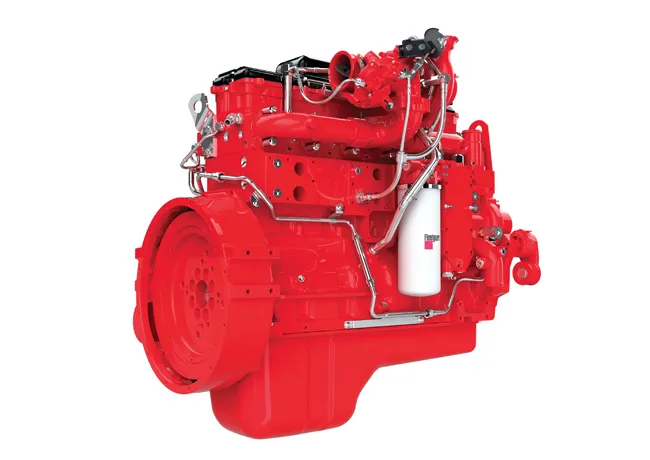

The EcoFit single module has been designed to work with Cummins’ Stage V engines when they arrive in 2019. “We could achieve Stage V with our current DPF-SCR system, however Stage V is an opportunity to take this technology further,” said Richard Payne, Cummins’ off-highway regulatory affairs director. The current proposal for Stage V emissions can still be amended before implementation in 2019 and 2020, but Cummins believes that every engine manufacturer will have to use a Diesel Particulate Filter (DPF) as part of its emissions solution to meet the required levels of Particulate Matter (PM). “Cummins has over a decade of experience in DPF and after-treatment technology with more than 590,000 DPF-SCR modules in use already,” said Jane Beaman, off-highway commercial leader at Cummins Emissions Solutions. “It is a concept at present but we’re exploring it for our entire range.” Advancements in catalyst technologies and efficiency improvements, plus Cummins’ investment in DPFs with higher ash capacities, allow for longer cleaning intervals in the filter. The SCR catalysts, coupled with the EcoFit UL2 liquid-only urea dosing system, offers enhanced NOx reduction with minimised fuel and AdBlue use. By making the DPF-SCR module smaller and lighter, Cummins will make it easier for equipment manufacturers to package the engine in their machinery. “Over the last few years we have seen continued demand for smaller, lighter high quality components to drive diesel engine efficiency improvements,” said sales and marketing director Suzanne Wells. “The latest technological enhancements enable us to meet these demands as well as offer greater versatility, which allows the development of tailored customer solutions.”