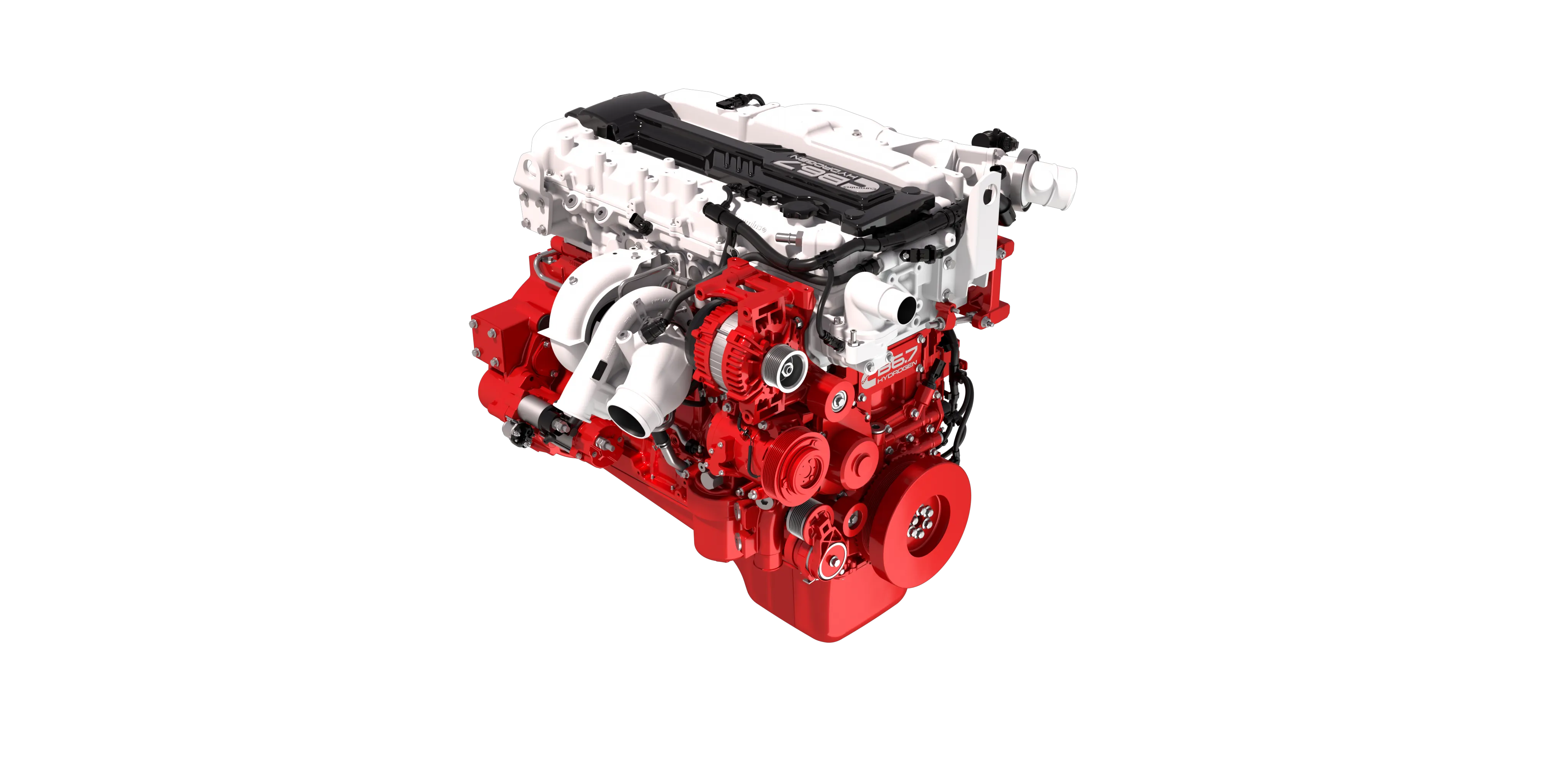

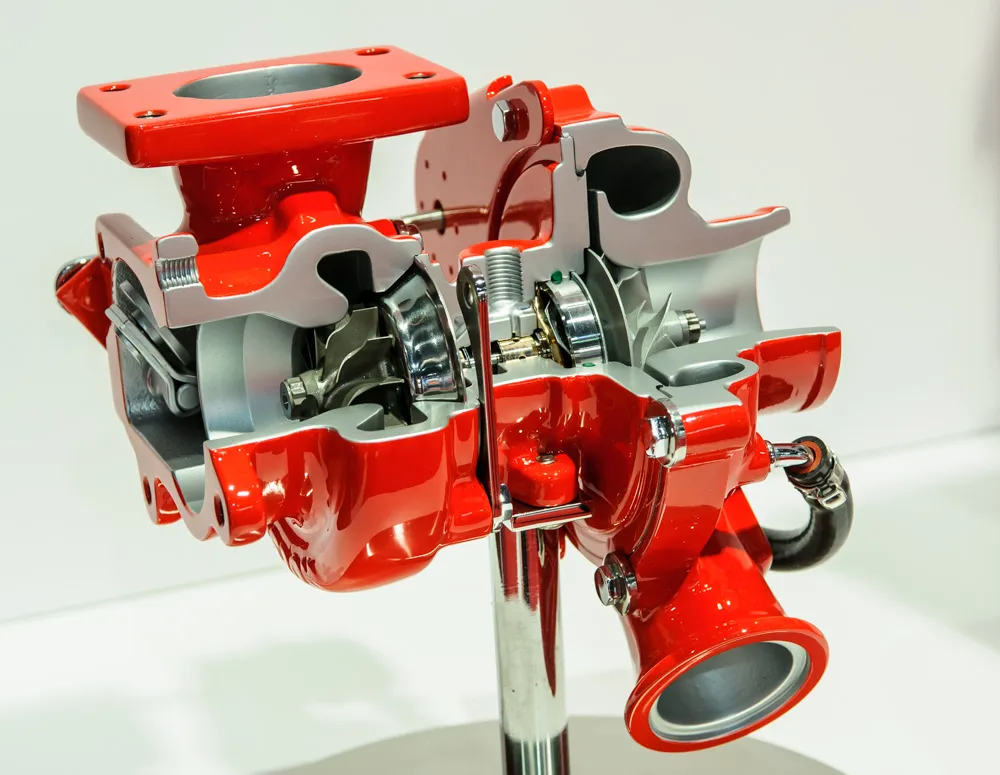

After launching its biggest turbocharger, the 900-series, Cummins used CONEXPO-CON/AGG to introduce its smallest.

Badged the 100-series, this back-to-basics design features a boost-controlled pneumatic wastegate, and is said to be suited to engines operating all variation of after-treatment system.

March 8, 2017

Read time: 1 min

After launching its biggest turbocharger, the 900-series,

Badged the 100-series, this back-to-basics design features a boost-controlled pneumatic wastegate, and is said to be suited to engines operating all variation of after-treatment system.

This HE150WG from the line-up has been engineered to suit power units from 2-4litres capacity.