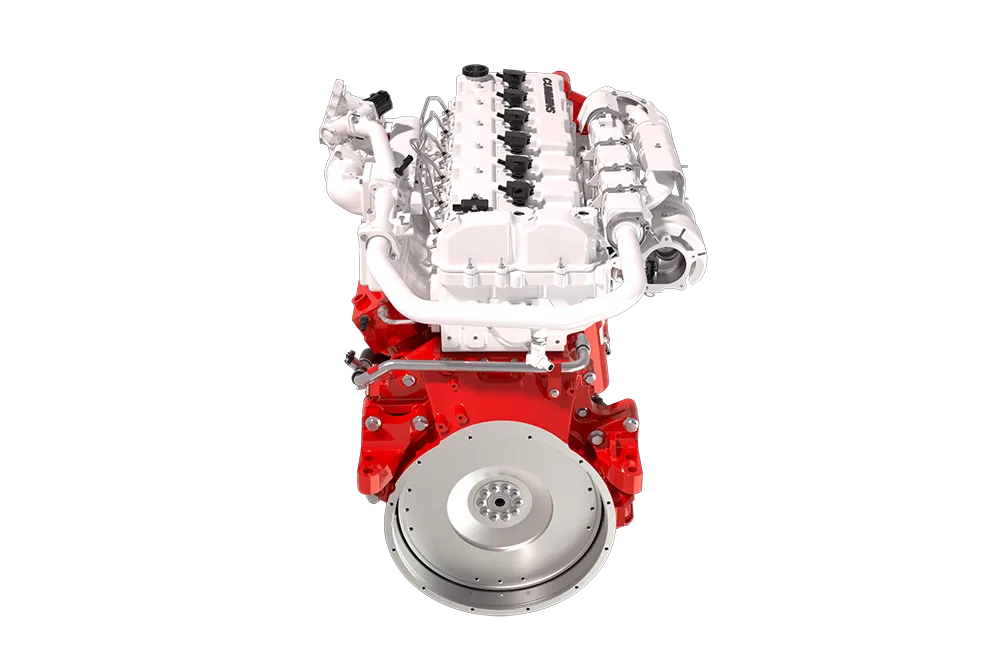

As part of its Destination Zero strategy, Cummins has created the fuel-agnostic engine series, designed to accelerate decarbonisation using combustion technology.

Taking combustion to new heights

Fuel-agnostic engines are single platforms with a shared base engine design, capable of accommodating a wide range of low-to-zero fuels. These fuels include diesel, natural gas, low-carbon biodiesel/HVO and hydrogen - which becomes zero-carbon fuel when produced using renewable energy sources.

By using low-to-zero carbon fuels in internal combustion engines, OEMs and their customers can benefit from reduced complexity, with the agnostic technology aligned with existing vehicle designs. The utilisation of compatible components also promotes economies of scale, as well as ensures comparable reliability and durability to diesel-powered solutions. As a result, OEMs and end users can embark on a faster and more cost-effective journey towards decarbonisation.

The Cummins fuel-agnostic 15-litre engine platform is rated 400–675hp and can be adapted for use with hydrogen, natural gas and advanced diesel. The hydrogen variant has ratings up to 530 hp (395 kW), and natural gas up to 510 hp (380 kW). Alternatively, advanced diesel engines can use sustainable HVO fuel, also known as renewable diesel or biodiesel, with ratings up to 675 hp (503 kW).

This high power density sets the standards for heavy-duty performance in key off-road applications, including excavators, wheeled loaders, drilling rigs, road planning, milling machines, haul trucks and air compressors. The agnostic approach will allow end users to pick the right powertrain for their application with the lowest CO2 impact.

The fuel-agnostic architecture of the Cummins 15-litre platform with a common base engine uses tailored cylinder heads and fuel systems to produce significant carbon reductions. Using B100 biodiesel enables up to a 70 per cent reduction in carbon, and using HVO renewable fuel achieves up to a 90 per cent reduction compared to diesel alternatives ‘from-well-to-wheel’.

Additionally, rather than just facilitating a move away from diesel, the development of the engine platform has enabled Cummins to squeeze even more performance from diesel fuel – with less CO2 emissions. In its diesel-fuelled form, the latest series of Cummins Performance Series engines will offer a broad power range of 450-to-675 hp (335-503 kW) with an impressive 3000 Nm peak torque.

Destination Zero

Today, operators can switch fleets to use ultra-clean, ultra-efficient diesel engines and take full advantage of technologies such as telematics and diesel substitutes to reduce emissions. Hydrogen-fuelled agnostic engines will offer operators and equipment manufacturers a heavy-duty zero-carbon solution based on easy-to-integrate technology. In the longer term, new technologies such as fuel cells and battery electric are anticipated to develop and become widely used zero-emission technologies.

Cummins continues to work towards a zero-emissions future with its Destination Zero 2050 strategy, with the business committed to developing combustion as part of a diverse portfolio of power solutions.

Content produced in association with Cummins