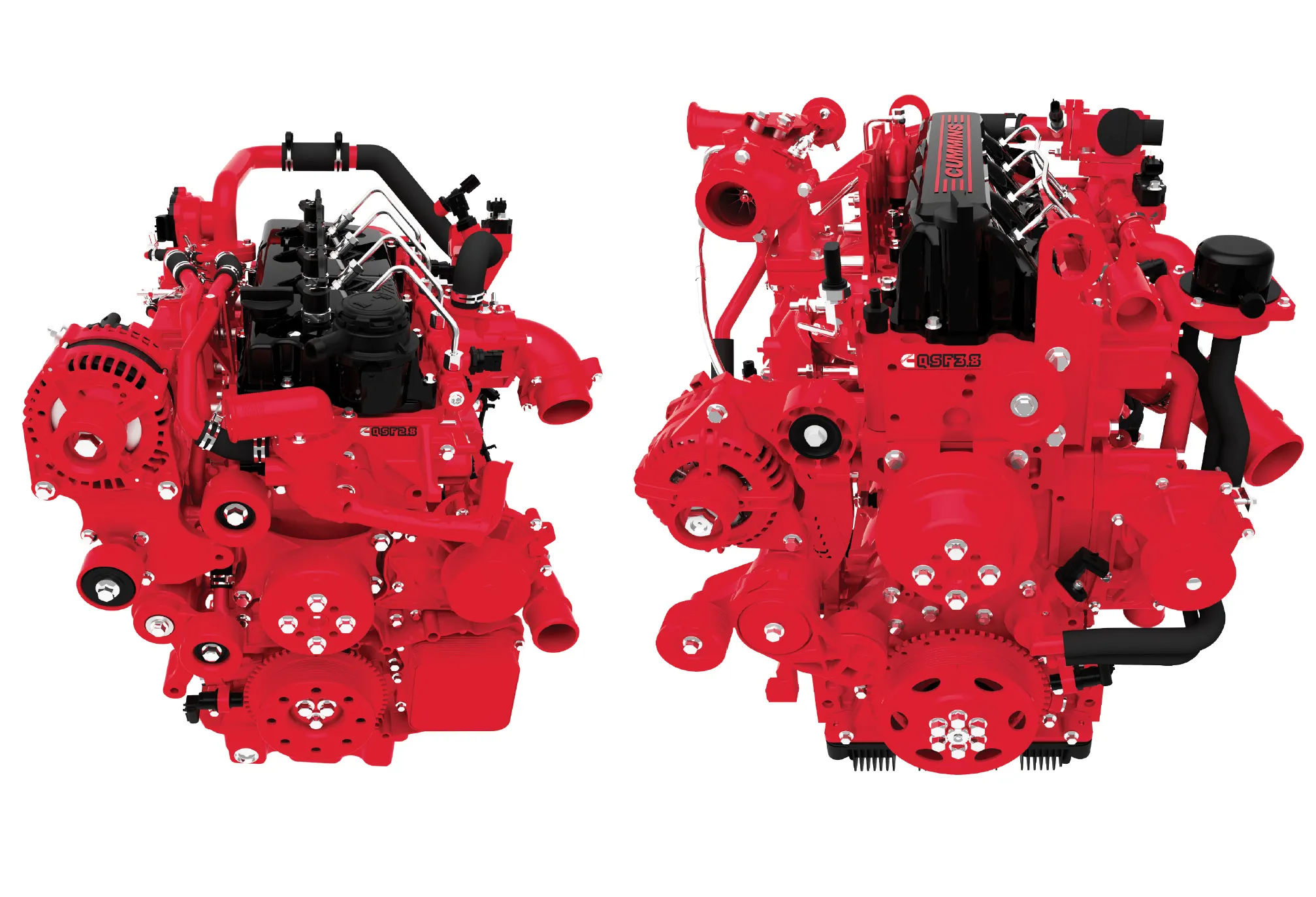

Cummins will extend its QSF engine line-up at Intermat with new configurations focused on simplified installation packages intended for rental equipment applications.

The engines, across the 37-55kW power range, meet EU and EPA low-emissions regulations, and the new QSF2.8 ratings will be introduced without Charge Air Cooling (CAC) to offer “a cost-effective power solution for space-constrained installations.” The QSF3.8 will be available at a lower 55kW rating with the Cummins ‘fit and forget’ Diesel Ox

January 29, 2015

Read time: 2 mins

The engines, across the 37-55kW power range, meet EU and EPA low-emissions regulations, and the new QSF2.8 ratings will be introduced without Charge Air Cooling (CAC) to offer “a cost-effective power solution for space-constrained installations.” The QSF3.8 will be available at a lower 55kW rating with the Cummins ‘fit and forget’ Diesel Oxidation Catalyst (DOC) offering the same service-free after-treatment provided by the smaller QSF2.8 engine.

“By adding these new configurations to the QSF2.8 and QSF3.8 engine range, we are anticipating a strong preference from rental companies to specify compact equipment that can offer the simplest solution and lowest cost of operation as they transition their fleets to meet lower emissions,” says Brian Wilson, Cummins general manager, Global Compact Business.

The simplified non-CAC version of the 2.8litre QSF uses an upgraded fuel injection-and-combustion formula able to retain the necessary torque and power delivery without the need for higher-density airflow. Removing the CAC system reduces cooling load on the equipment, freeing up space and simplifying the engine installation.

The QSF2.8 without CAC is available at 37-48kW ratings for both 2,200rpm and 2,500rpm applications. The non-CAC ratings join the existing QSF2.8 line-up with CAC from 37-55kW at 2,500 rpm configured for applications with more demanding duty cycles.

The QSF3.8 will move down to a 55kW rating, bringing the benefit of the smaller, ‘fit and forget’ Cummins DOC-only to a broader range of rental equipment applications. This after-treatment downsizing will allow equipment positioned in the 56-67kW category to eliminate the need for “a more complex Selective Catalytic Reduction (SCR) or Diesel Particulate Filter (DPF) system.”