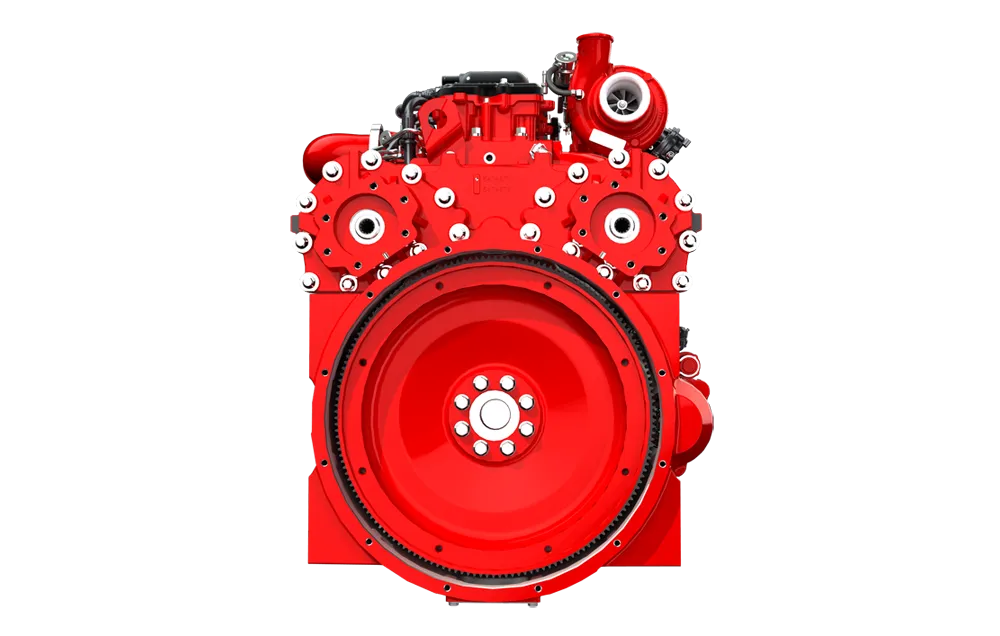

Cummins has revealed a new generation of ultra-low emission diesel engines that have been engineered to meet forthcoming EU Stage V emissions regulations. The engines include F3.8, B4.5, B6.7 and L9 variants with capacities from 3.8-9litre and spanning 75-321kW. Importantly, all have ditched EGR, creating a mechanically simpler package that delivers more power, more torque and lower fluid consumption, said Cummins - while maintaining the same capacity as the engines they replace.

“Removing EGR allowed us

April 12, 2016

Read time: 2 mins

The engines include F3.8, B4.5, B6.7 and L9 variants with capacities from 3.8-9litre and spanning 75-321kW. Importantly, all have ditched EGR, creating a mechanically simpler package that delivers more power, more torque and lower fluid consumption, said Cummins - while maintaining the same capacity as the engines they replace.

“Removing EGR allowed us to realise the full potential of the engine for Stage V, without increasing displacement size,” said Jim Fier, Cummins vice president of engineering. “Our 12litre engine already pointed the way forward for a successful EGR-free design at Stage V, so we were able to cascade this simpler approach down through the power range.”

Engine operating costs will be further reduced said Fier, through 1,000-hour service intervals – twice that of the current service interval. Larger sumps, with greater oil-holding capacity, play a part in this improvement. Smarter electronics will bring stop-start technology, while a single turbocharger with high-efficiency wastegate adds to the simplistic approach.

Exhaust after-treatment for Stage V will be achieved using a single module, said Fier. This combines a DPF, SCR and urea dosing technology in one module, providing a reduction in package size by up to 50%, with a weight saving of up to 30%, Cummins claimed.