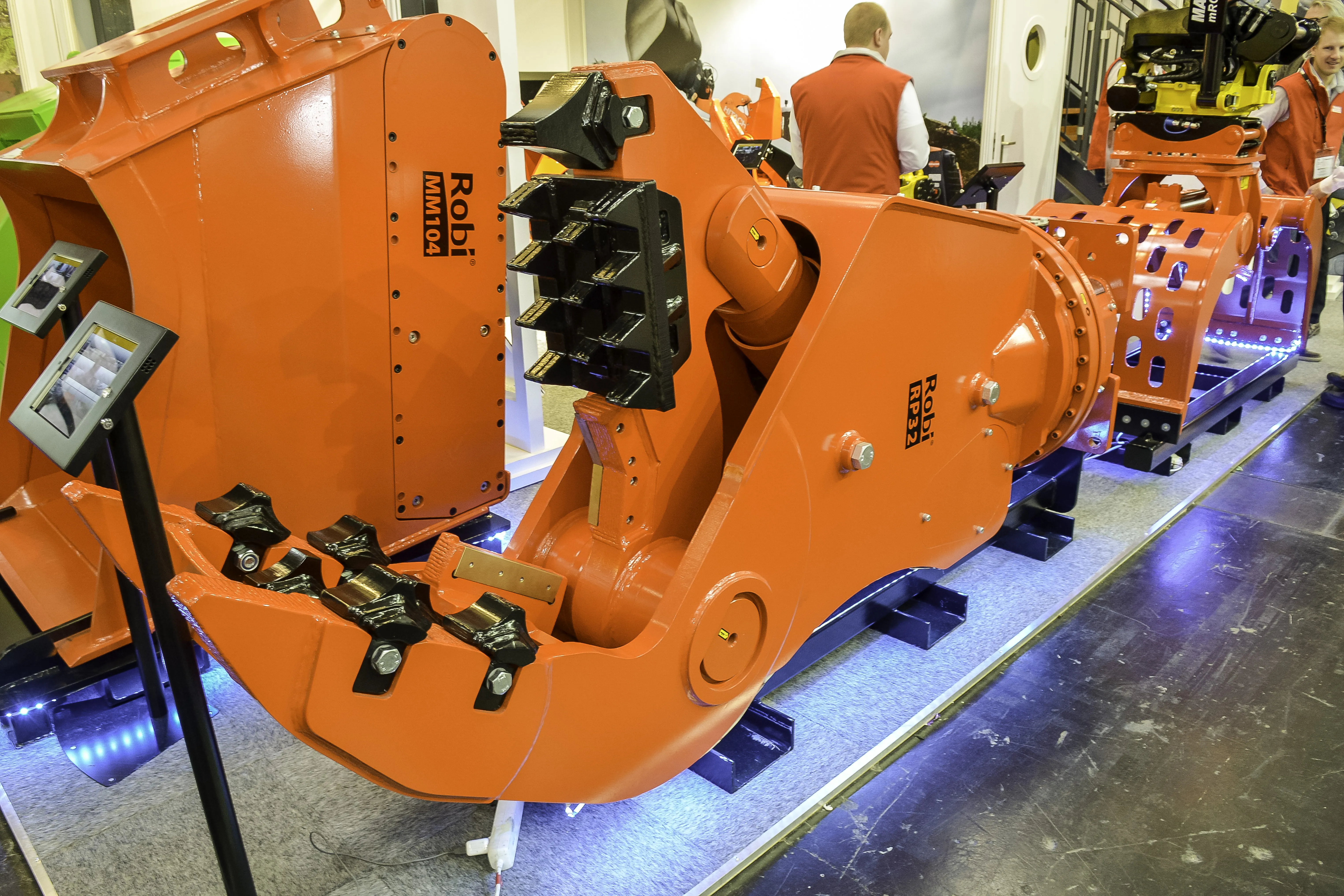

Finnish attachments manufacturer Ramtec has developed the Robi RP32 rotating pulveriser. Designed for excavators in the 22-35tonne class, the RP32 features interchangeable work tools enabling the pulverising mechanism to be swapped for bolt-on crushing components. An integral shear plate enables the attachment to cut smaller materials – typically up to 100mm size, said the company.

April 15, 2016

Read time: 1 min

Finnish attachments manufacturer 2172 Ramtec has developed the Robi RP32 rotating pulveriser. Designed for excavators in the 22-35tonne class, the RP32 features interchangeable work tools enabling the pulverising mechanism to be swapped for bolt-on crushing components. An integral shear plate enables the attachment to cut smaller materials – typically up to 100mm size, said the company.