According to

As with its siblings, the machine now benefits from the firm’s latest ergonomic Maxcab, which provides a good all-round view. The layout and design of the controls and the joysticks have been revised with the consoles mounted directly on the seat.

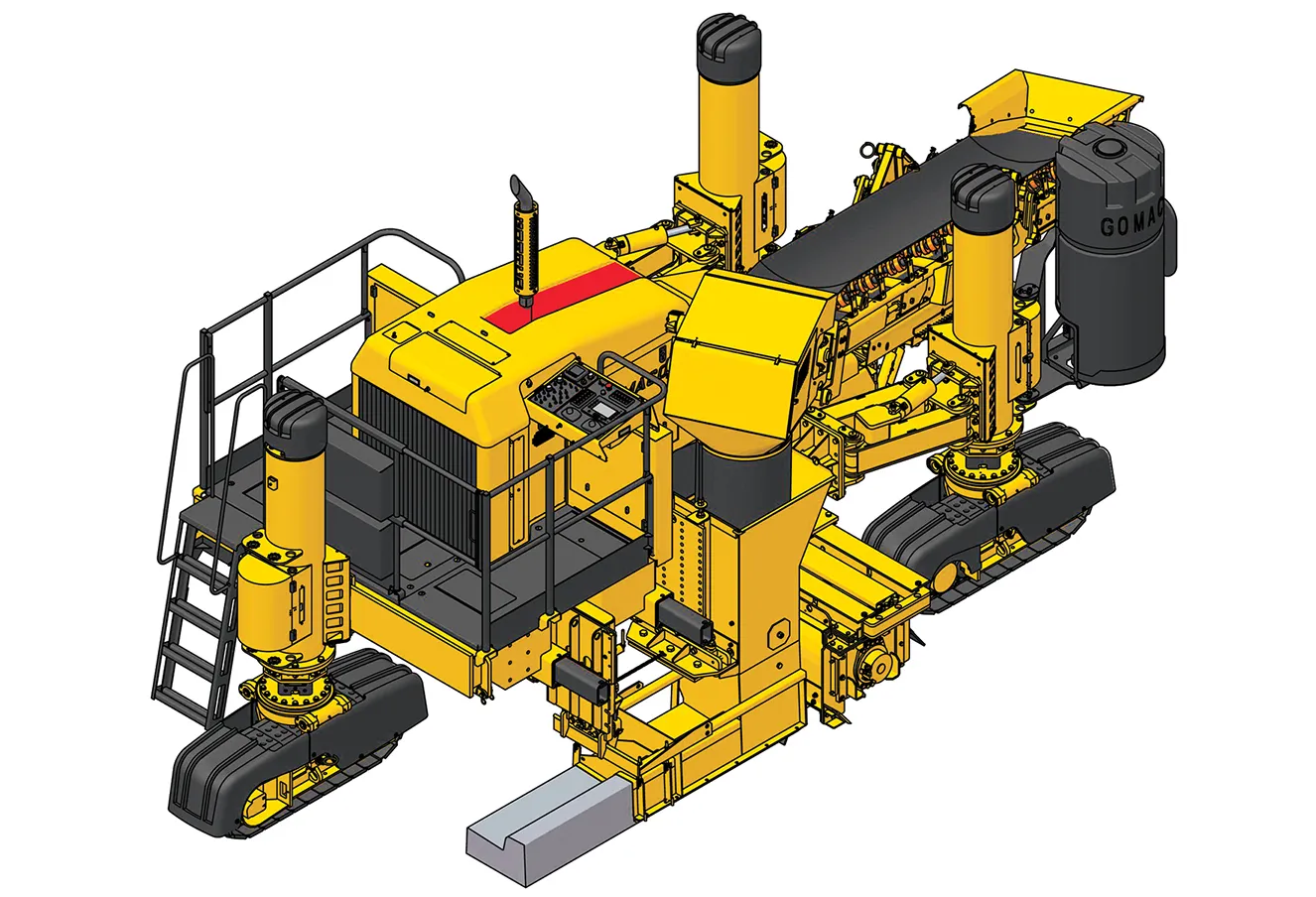

The new exterior design features a weight-reduced plastic cladding and is also said to set new standards for maintenance and ease of service. The undercarriage has been raised by 75mm in order to optimise servicing, while central lubrication points for pivot points and the slewing ring reduce servicing needs.

The railing on the uppercarriage can now be folded inward for easier transportation from job to job. Another new feature is the flange-mounted double collapsible jib. The fly boom is bolted on to the main boom and can be folded in two stages, enabling hook heights of up to 50m to be achieved quickly, reducing set-up time on site. The proven boom system is retained for versatility on site. The 673 R-HD meets the latest Stage V emission standards and is powered by a 186kW diesel with good fuel economy.

Another key feature is the use of the latest SENCON control and diagnosis system. The set-up program is selected using a soft key and the machine is said to have optimised control technology for precise operation.