GKN Land Systems has launched a range of service-free driveshafts at Conexpo. Developed exclusively for off-highway applications, the Synergy range of inverted slip design driveshafts combines the benefits of GKN’s Rockford and Bruneck ranges. Doing so has allowed the firm to reduce overall driveshaft weight without compromising on strength and durability.

March 6, 2014

Read time: 1 min

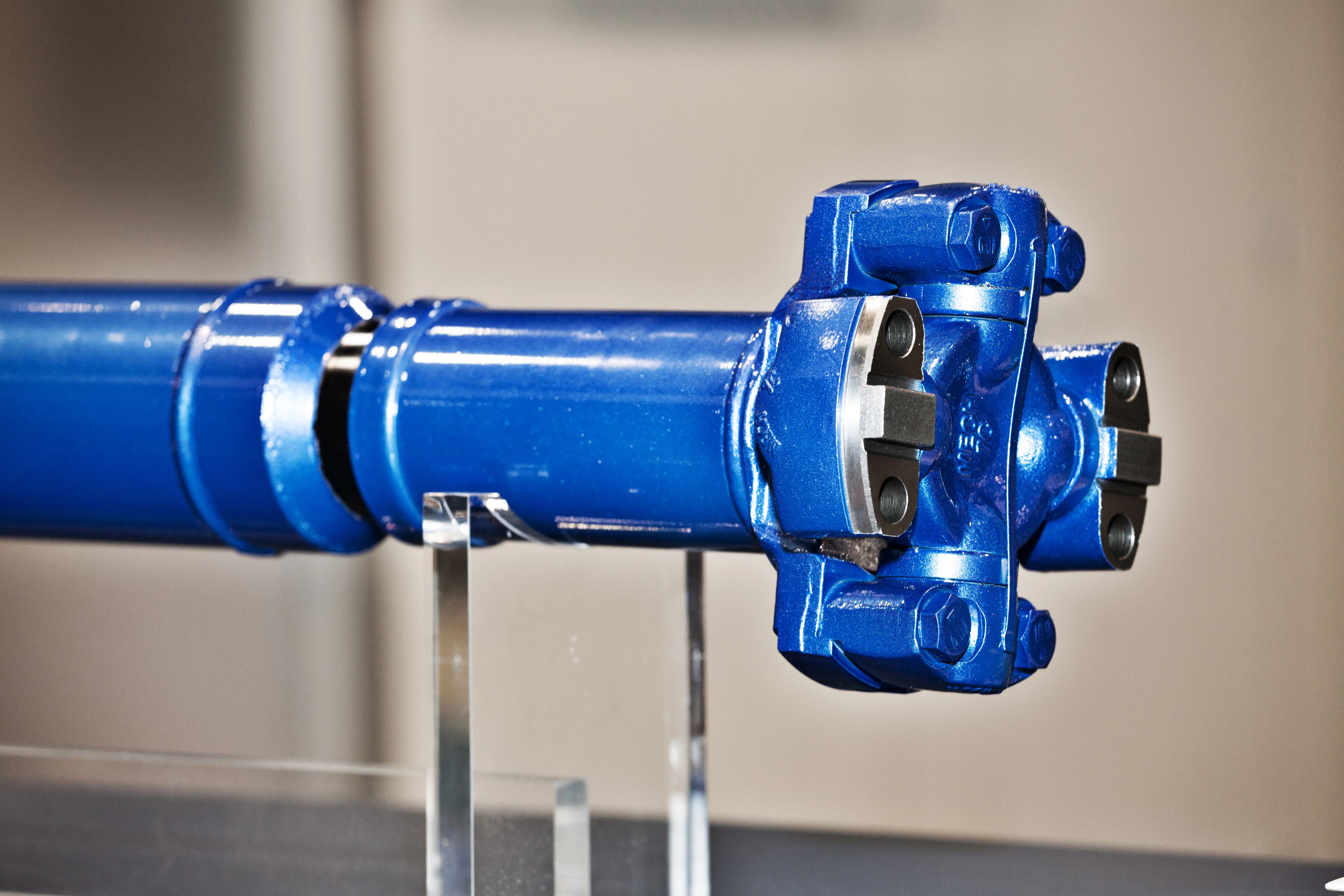

GKN Land Systems has launched a range of service-free driveshafts at Conexpo. Developed exclusively for off-highway applications, the Synergy range of inverted slip design driveshafts combines the benefits of GKN’s Rockford and Bruneck ranges.

Doing so has allowed the firm to reduce overall driveshaft weight without compromising on strength and durability.

The new range enjoys simpler installation by using a four-bolt flange on both ends of the driveshaft. Advanced sealing technology combined with optimised greasing for the life of the shaft has led the firm to a service-free solution for off-highway applications.

%$Linker:2 External <?xml version="1.0" encoding="utf-16"?><dictionary /> 0 0 0 oLinkExternal www.gknlandsystems.com Visit GKN Website false http://www.gknlandsystems.com/ false false %>

Doing so has allowed the firm to reduce overall driveshaft weight without compromising on strength and durability.

The new range enjoys simpler installation by using a four-bolt flange on both ends of the driveshaft. Advanced sealing technology combined with optimised greasing for the life of the shaft has led the firm to a service-free solution for off-highway applications.

%$Linker: