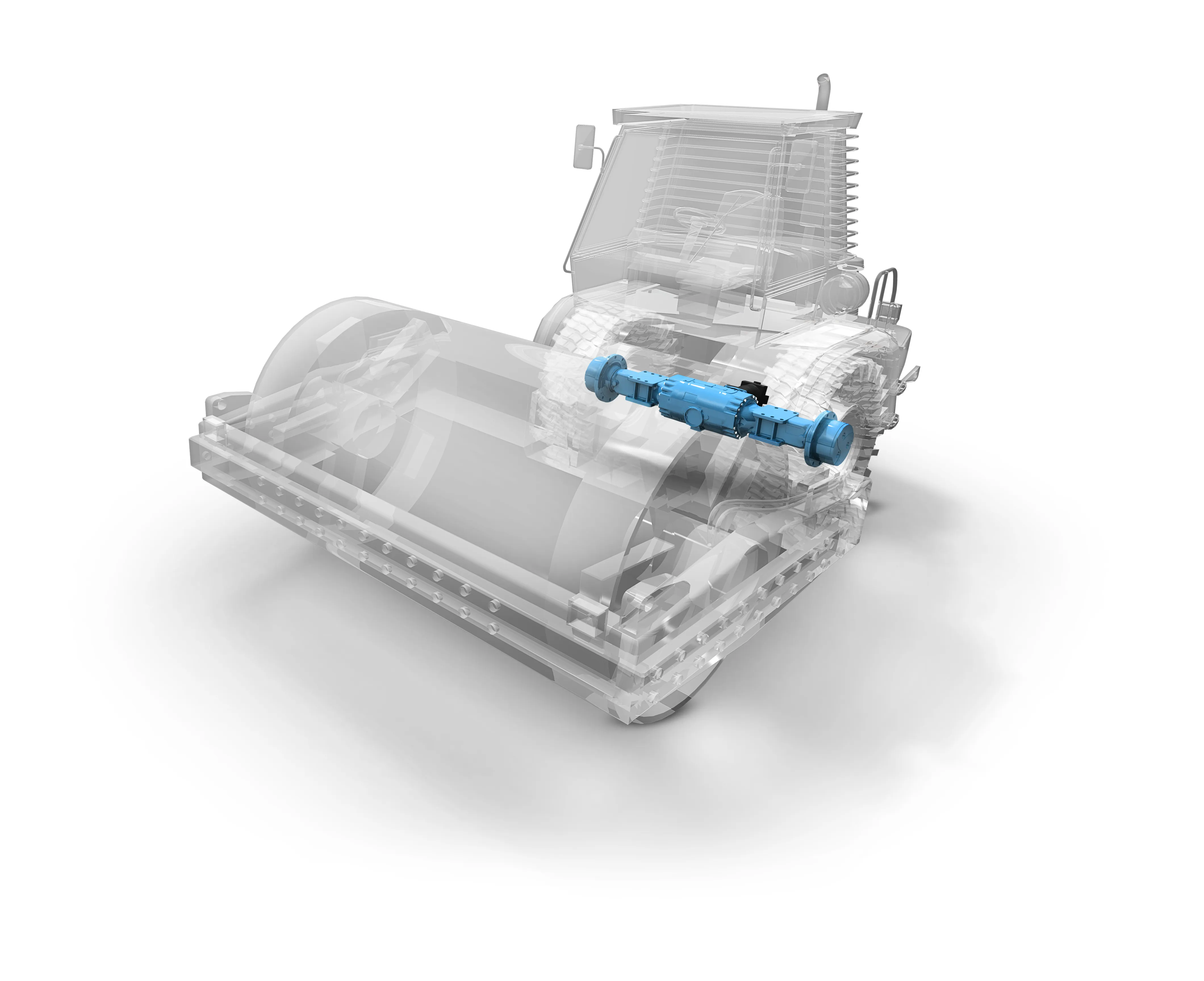

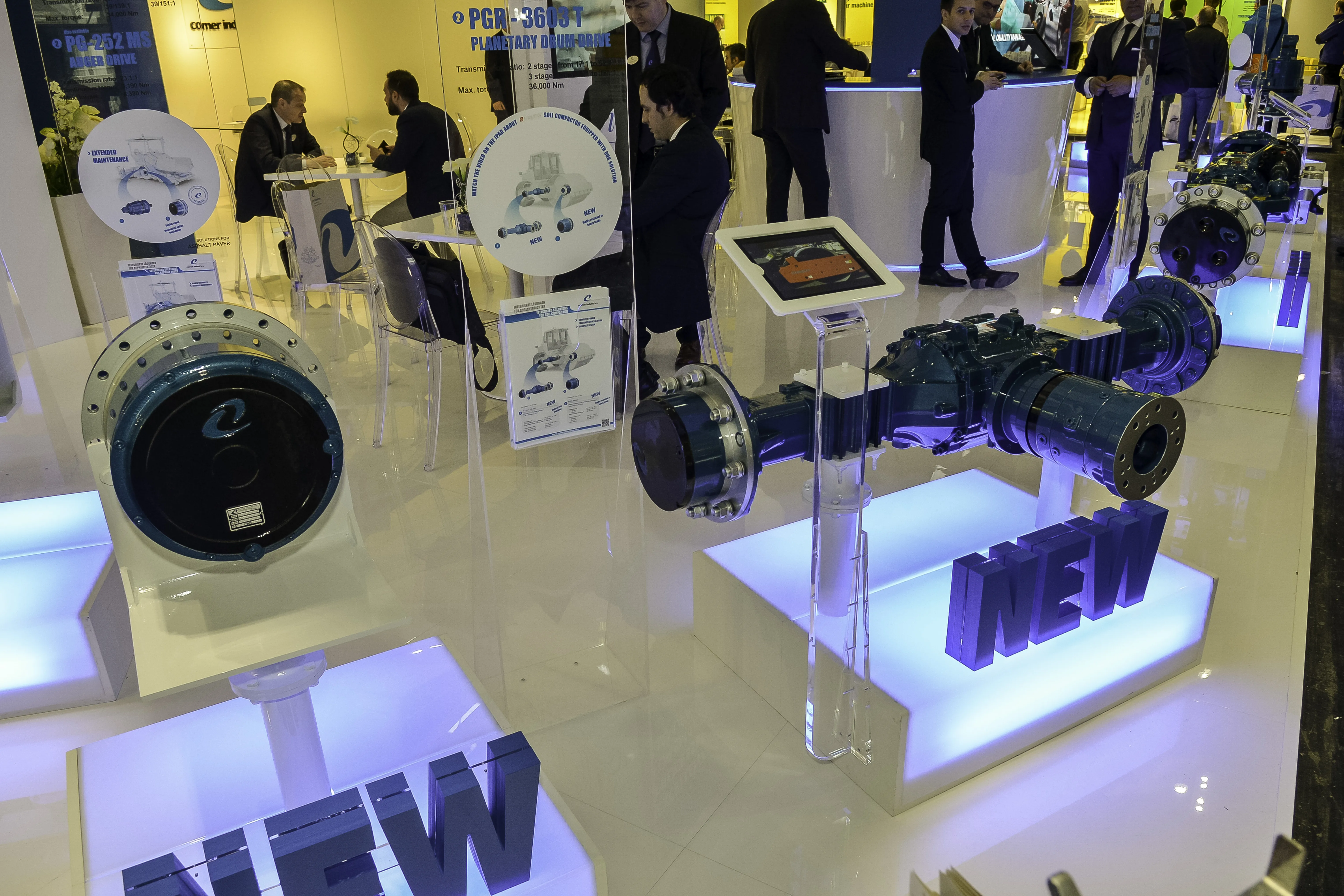

Comer has introduced a complete power transmission solution with a compact design to suit the soil compactor sector. The system comprises the F-128 axle plus the PG-161 planetary drive for the rear axle drive line and the PGR-3603 T planetary drum drive for the front drum.

The rear axle drive line has a high transmission reduction ratio to nearly 140:1 and a compact design which allows for the pump and hydraulic motor to be smaller than usual. The axle is equipped with a pre-loaded limited slip different

April 15, 2016

Read time: 1 min

The rear axle drive line has a high transmission reduction ratio to nearly 140:1 and a compact design which allows for the pump and hydraulic motor to be smaller than usual. The axle is equipped with a pre-loaded limited slip differential and can be built with an internal spring applied/hydraulic release (SAHR) parking brake. With a maximum dynamic load of 6.6 tonnes, coupled with a maximum output torque of 2400 daNm, the F-128 axle is suitable for single drum rollers with an operating weight of up to 9 tonnes.