Comer Industries has expanded its product range offer in the mobile equipment market with new, high end, rotating housing, planetary drives. The new PGRF-7003, 9003 and 11003 models are said to be more compact and rugged, as well as being interchangeable. The firm says that the units meet a need for more demanding technical requirements from major OEMs and the market. With this new introduction, Comer Industries’ rotating housing product portfolio ranges now from PGRF-802 with rated peak torque of 10,000Nm

January 6, 2017

Read time: 2 mins

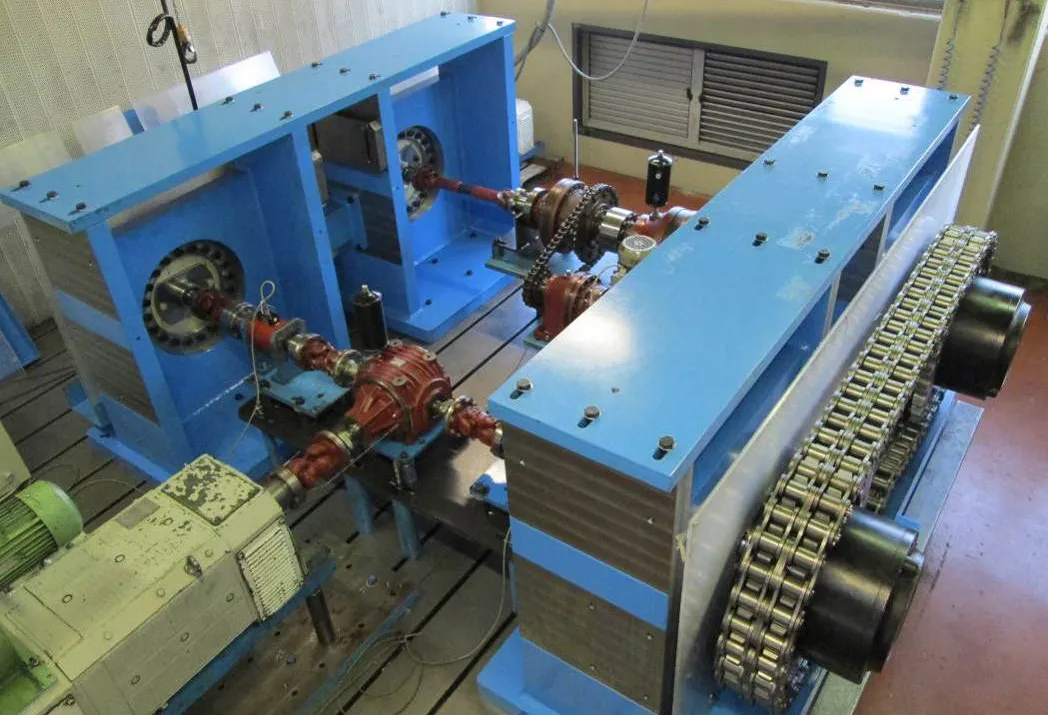

These planetary final drives suit heavy duty applications and have been tested extensively in the laboratory and in the field by selected customers. The testing is said to have proven the robustness and reliability of these heavy duty drive units according to the firm.

As tangible results of all these activities, Comer Industries has started serial production on a few applications. The ground sun and planet gears, meshing with the nitrited ring gears and being supported by forged alloy steel planet carriers, are said to give the PGRF-11003 the reliability required for rugged off-highway applications where high shock loads are common. In addition, the usage of high load tapered roller bearings, instead of spherical ball bearings, guarantee less specific pressure on the rollers and longer life, even in presence of heavy weight machines or high pulling force.

This planetary design and layout - which can fit a sprocket, a rim of a wheel, a winch, or a drum - can be used across a wide range of heavy-duty machines. This design offers a wide range of ratios, is designed to fit all the most common axial piston motors, has a parking and emergency brake with multiple friction discs, a different interface lay out and a disconnection option for towing.