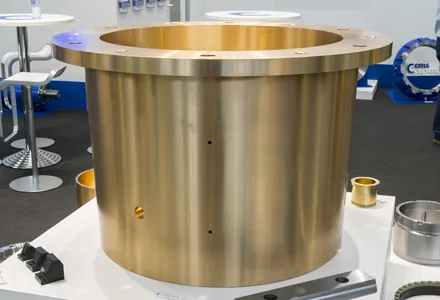

It’s big, bold and bronze, the new 1tonne spider replacement bushing made by CMS Cepcor, one of Europe’s largest aftermarket manufacturer and supplier of crusher spares and services.

CMS, which caters to the global quarrying, mining, demolition and recycling industries, made the bushing for use in gyratory crushers, for client FLSmidth, a Danish supplier of systems, machinery, processes, spare parts and services to the worldwide mineral industry.

“The bushing is an example of what CMS’s recently opene

April 19, 2016

Read time: 2 mins

It’s big, bold and bronze, the new 1tonne spider replacement bushing made by 6017 CMS Cepcor, one of Europe’s largest aftermarket manufacturer and supplier of crusher spares and services.

CMS, which caters to the global quarrying, mining, demolition and recycling industries, made the bushing for use in gyratory crushers, for client7001 FLSmidth, a Danish supplier of systems, machinery, processes, spare parts and services to the worldwide mineral industry.

“The bushing is an example of what CMS’s recently opened factory in the town of Coalville, in the UK county of Leicestershire, can do,” a spokesperson for the company said. Last year, CMS Cepcor increased its CNC and manual turning capacity with the purchase of two new machining centres for making precision machined crusher parts and crusher repairs.

Bronze spider bushings are made in size ranges from 200kg to more than 1tonne.

CMS’s new centre is manufactured by Doosan and complements other Doosan CNC machine tools, including a Doosan Puma 700XLM, Puma 400XLB and Puma 400LB turning centres as well as Mynx 7500 vertical machining centre.

CM’s UK manufacturing facilities include CNC, milling, turning, boring, slotting, grinding, drilling, welding, co-ordinate measuring and material testing.

Among CMS-supported brands are161 Atlas Copco, Fuller 2760 Traylor, Goodwin Barsby, 2200 Kobelco, 2300 Komatsu, Krupp and 1222 Terex-Finlay.

CMS Cepcor replacement crusher parts have full traceability within our Lloyd's Register QA ISO9001:2008 certified quality system.

All videos

CMS, which caters to the global quarrying, mining, demolition and recycling industries, made the bushing for use in gyratory crushers, for client

“The bushing is an example of what CMS’s recently opened factory in the town of Coalville, in the UK county of Leicestershire, can do,” a spokesperson for the company said. Last year, CMS Cepcor increased its CNC and manual turning capacity with the purchase of two new machining centres for making precision machined crusher parts and crusher repairs.

Bronze spider bushings are made in size ranges from 200kg to more than 1tonne.

CMS’s new centre is manufactured by Doosan and complements other Doosan CNC machine tools, including a Doosan Puma 700XLM, Puma 400XLB and Puma 400LB turning centres as well as Mynx 7500 vertical machining centre.

CM’s UK manufacturing facilities include CNC, milling, turning, boring, slotting, grinding, drilling, welding, co-ordinate measuring and material testing.

Among CMS-supported brands are

CMS Cepcor replacement crusher parts have full traceability within our Lloyd's Register QA ISO9001:2008 certified quality system.

All videos