8592 CMI Concrete Machinery has introduced an upgraded SF-3 two-track slipform paver at the CONEXPO-CON/AGG show in Las Vegas. With a hydraulically-extending frame on both sides of the machine, paving widths range from 3.66m to 7.92m. The machine can also be supplied with bolt-in mainframe extensions, taking paving widths to a maximum 11m.

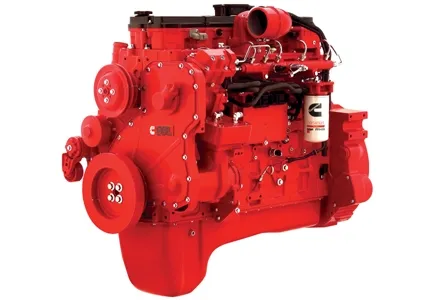

The SF-3 is powered by a Tier 4 Final Cummins QSG12 diesel engine delivering 336kW. This drives through a dual range hydrostatic drive system to track frame-mounted motors and gearboxes. With a shipping weight of 39 tonnes, at 11m width, the SF-3 has a maximum paving depth of 457mm.