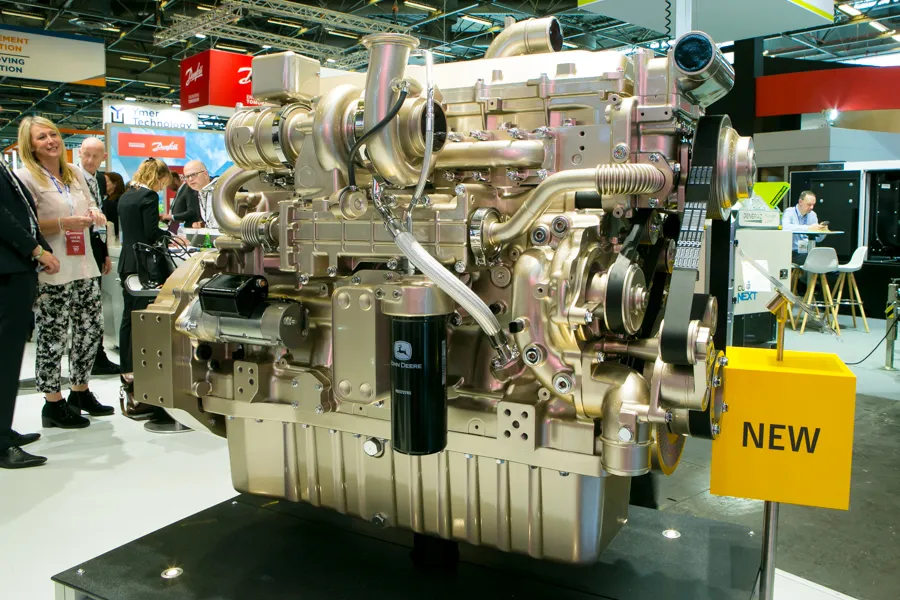

John Deere power Systems claims that its new 13.6litre diesel combines low emission levels with a high power density. According to Deere account manager Vincent Lauriol, the firm will meet the requirements of Stage V, based on proven technology already used in the Stage IV compliant units.

“There will also be a non-certified platform also for lower regulated markets,” said Lauriol, adding that the manufacturer has yet to decide whether these will be Tier 2 or Tier 3 compliant. Whatever happens, Deere will tailor these units to the needs of the local market in question.

The new 13.6litre engine is a refinement of earlier models. Power density is being increased by 14% while torque is being boosted by 11%. The high pressure fuel injection system has been further refined, boosting combustion efficiency and helping to reduce fuel consumption by around 7%.

According to Lauriol, the new engine scores in other respects: “We have designed the engine to be easy to access for maintenance purposes and it is compact. The overall package is small for a 13.6litre engine.”

He said that the engine envelope is around 18% more compact than that of the previous Deere engine in this class, while its weight has been reduced by 10% to 1.488tonnes. The emissions control package includes DOC, DPF and SCR technologies operating in-line, with integrated DEF injection.

Maintenance needs are low for this engine class and there is no need for valve lash adjustment as the unit now has hydraulic adjusters. And this has an added benefit says Lauriol: “It cuts engine noise.”