Deutz is introducing an engine that will run on hydrogen as well as electric power retrofit options for off-highway machines. These form part of the firm’s programme aimed at reducing carbon emissions.

This programme represents a substantial investment in research & development for Deutz. Bert van Hasselt, head of Sales and Service for Deutz’s BU Green division said, “We are investing €100 million until the end of next year.”

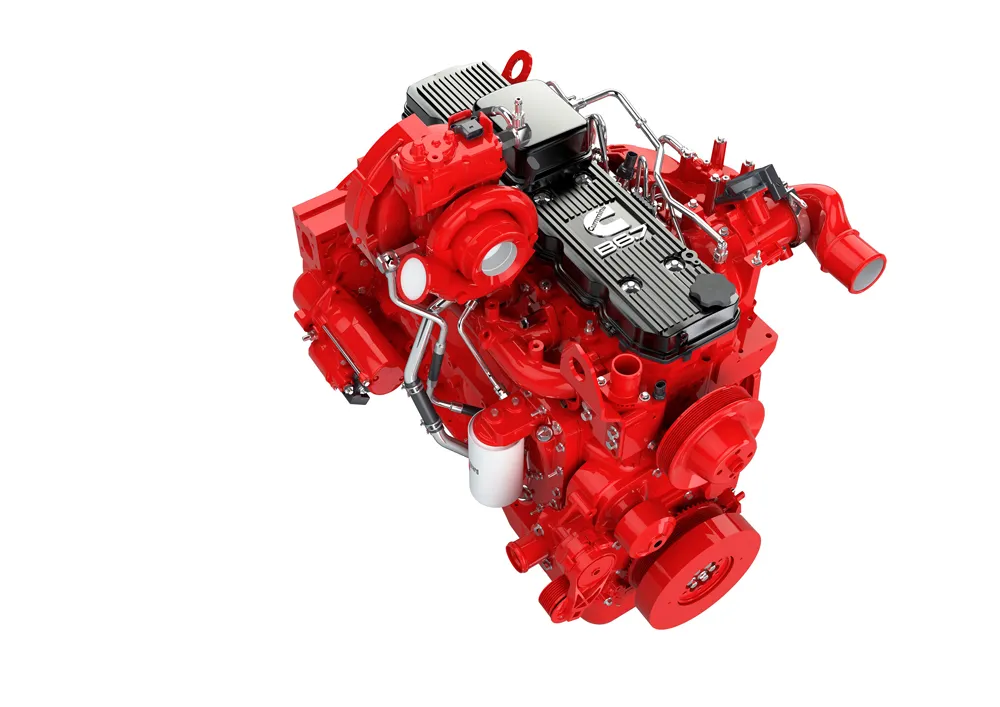

The new hydrogen engine in testing is the TCG7.8H2 unit, a 7.8litre engine that will deliver 228kW. The first production units will be manufactured in the third quarter of 2024 and will be aimed at genset or rail applications initially, with an order of 100 units being supplied to China. However, once the units have been proven in these applications further duties will be available, including installations into construction machines. According to van Hasselt, the continuing high price of hydrogen as a fuel means that the unit sales will remain low until a better hydrogen supply infrastructure (and more reasonable fuel prices) becomes available.

In the meantime, Deutz believes its electrification retrofit package will be of interest for customers with existing fleets of equipment that is still comparatively new. These can be tailored to a wide range of equipment applications. According to van Hasselt, “We can retrofit equipment with diesel engines with an electric system. It’s part of the transition into the new world.”

To further expand the electrification range, Deutz is offering its onsite PowerTree package, which can provide electric power onsite with ratings from 30kW/h up to 2MW/h.

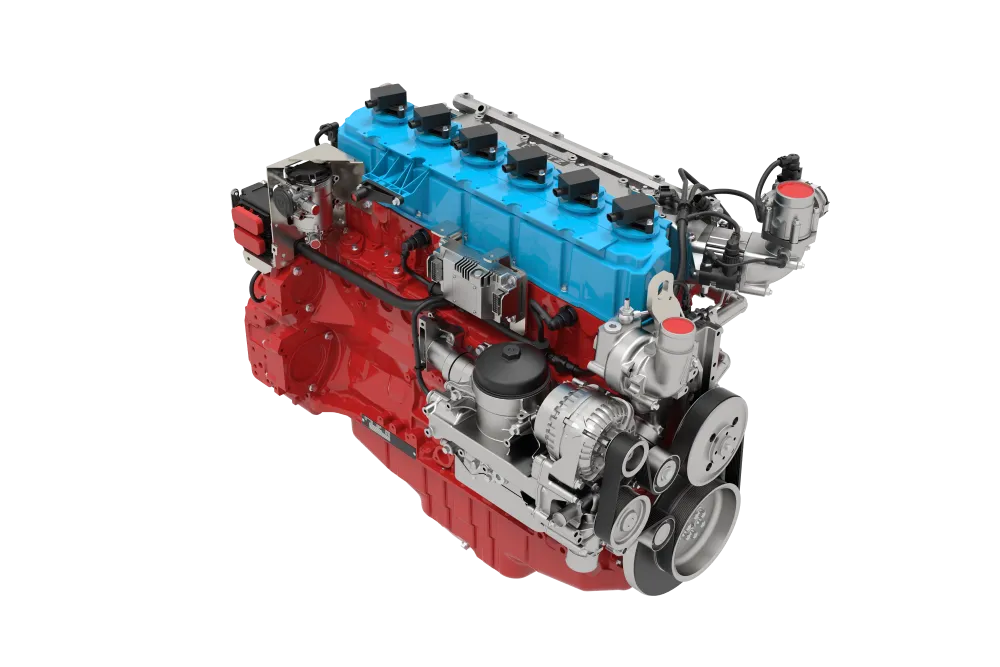

In addition however, Deutz still believes there is demand for conventional diesels and is introducing the TCD2.9 unit, a 2.9litre engine which meets Stage 5/Tier 4 Final emissions requirements has been developed jointly with John Deere. Coming later will be the TCD3.9 unit, also developed jointly with John Deere and due to enter field test in mid-2024, offering ratings from 75-130kW.