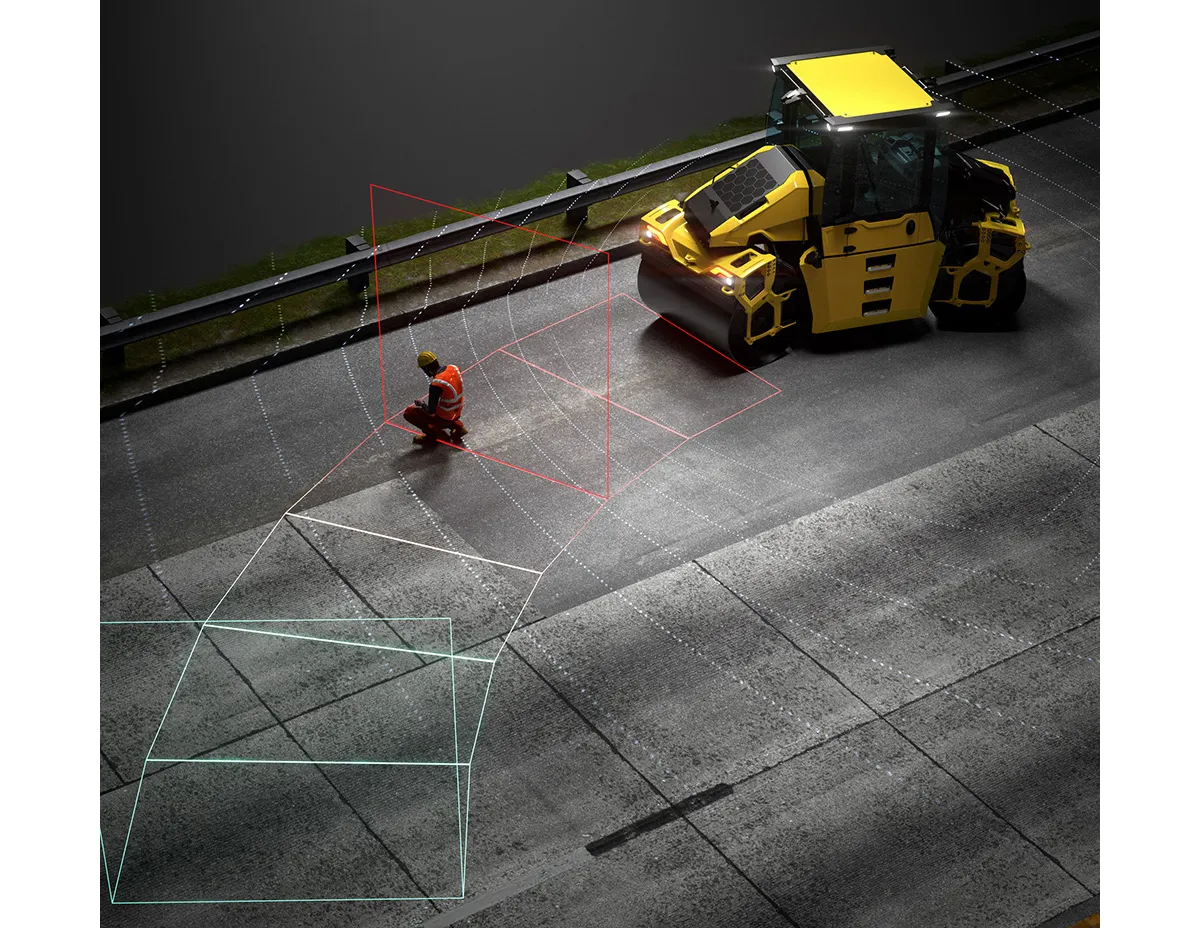

Case Construction Equipment has unveiled a new concept machine, developed by the Construction Equipment segment’s Innovation Department in collaboration with CNH Industrial Design.

The manufacturer says the forward-thinking concept represents a significant leap in automation, offering a glimpse into the next generation of construction equipment.

Fabrizio Cepollina, newly-appointed head of CNH CE EMEA, said: “By integrating zero-emission technologies, AI-driven automation, and enhanced connectivity, we are not just building machines – we are shaping the future of the construction industry, thanks to the passion and proven expertise of our team that drives our strategy.”

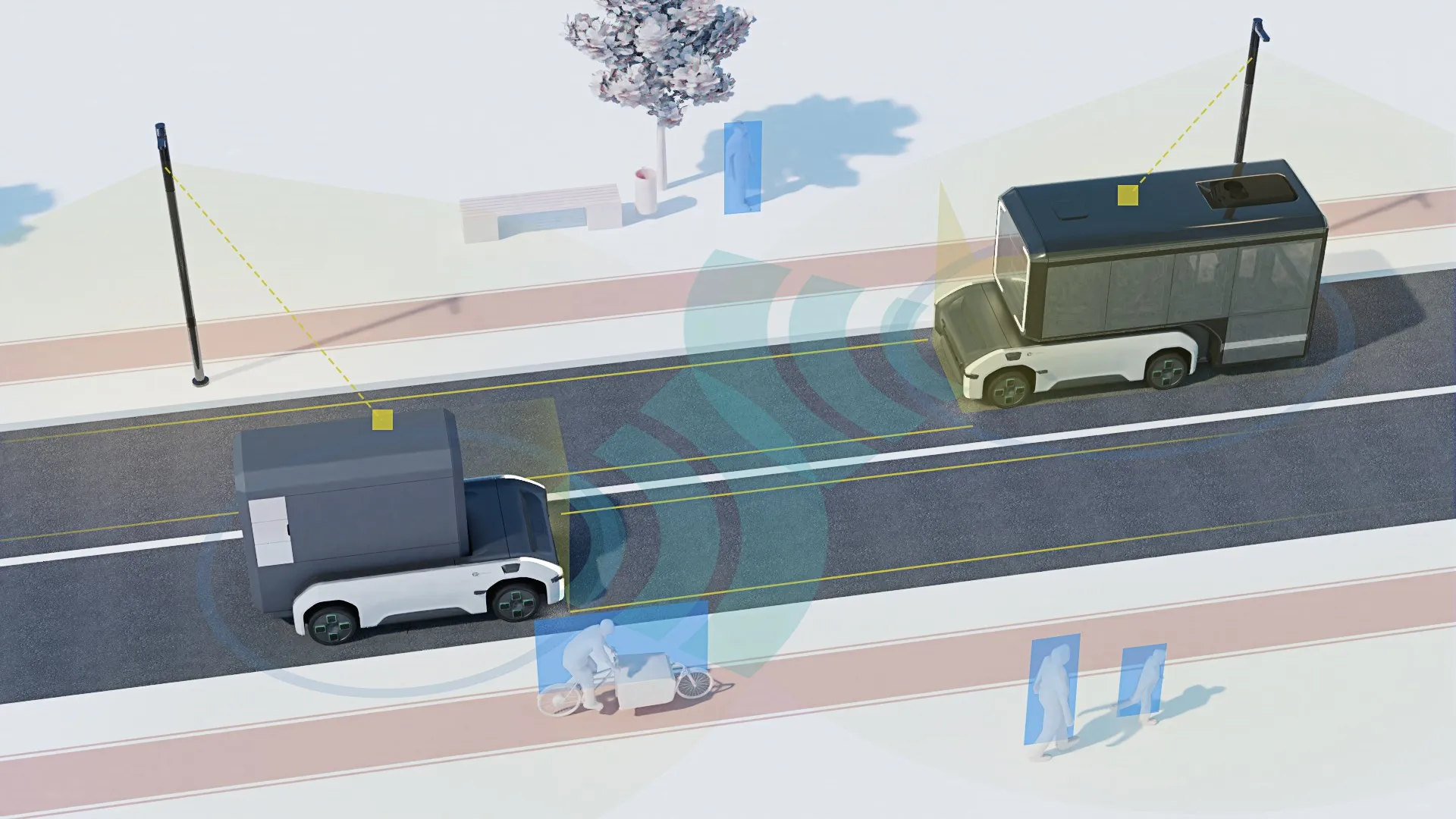

Case is offering advanced driver assistance systems for its wheeled loaders. These are designed to enhance safety, efficiency and productivity on the job site. The new systems include better visibility, obstacle and hazard perception, AI-based driving assistance and semi to fully-autonomous loader operations.

To further support safety and productivity, Case is also introducing advanced remote monitoring technology, providing remote machine assistance. This technology enables real-time monitoring of operational conditions and fuel consumption and facilitates predictive maintenance, ultimately reducing downtime and improving fleet management.

Case is also showcasing a special edition SV340B skid steer loader, drawing inspiration from Metallica's James Hetfield. This custom-designed skid steer loader follows the successful presentation of the first machine, TV450B, to James Hetfield in person at the YouTube Theatre in California, USA, at the Helping Hands charity concert, organised by the band’s All Within My Hands charitable foundation. The second machine, SV340B, is decorated with visuals that recall the band’s graphics, personal tattoos and album artwork.

In line with its ‘Road to the Future’ campaign, launched in 2023, Case says it continues to advocate for the widespread adoption of innovative technologies, underscored by its bold ‘Let’s Drive The Future’ approach.

Humayun Chishti, president of CNH Construction, says that the Construction segment within CNH plays a pivotal role as a hub for pioneering solutions focused on automation and connectivity

“It underscores our unwavering commitment to delivering sustainable, efficient, and innovative solutions that not only meet today’s demands but also anticipate the needs of tomorrow’s customers,” Chishti added.

Stand FM. 714/9