To serve the specific needs of the Indian market, Lintec & Linnhoff has appointed Gainwell Engineering to begin production of a new asphalt plant series with immediate effect. The Linnhoff DRX and TSD asphalt plants benefit from a range of advanced operating features and benefits, and will be sold and serviced through the Gainwell Commosales network.

Lintec & Linnhoff introduced its new Linnhoff DRX DurableMix asphalt plant series at the Excon India 2022 exhibition in Bengaluru. The firm also launched its locally manufactured Linnhoff TSD1500 MobileMix asphalt plant.

There are now two models in the new Linnhoff DRX series. These are the DRX1500DS, with a maximum capacity output of 120tonnes/hour and the larger DRX2000DS, with a maximum capacity output of 160tonnes/hour. Both units offer productive operation with a batch cycle time of between 45 and 55 seconds and share a range of features familiar to Linnhoff customers.

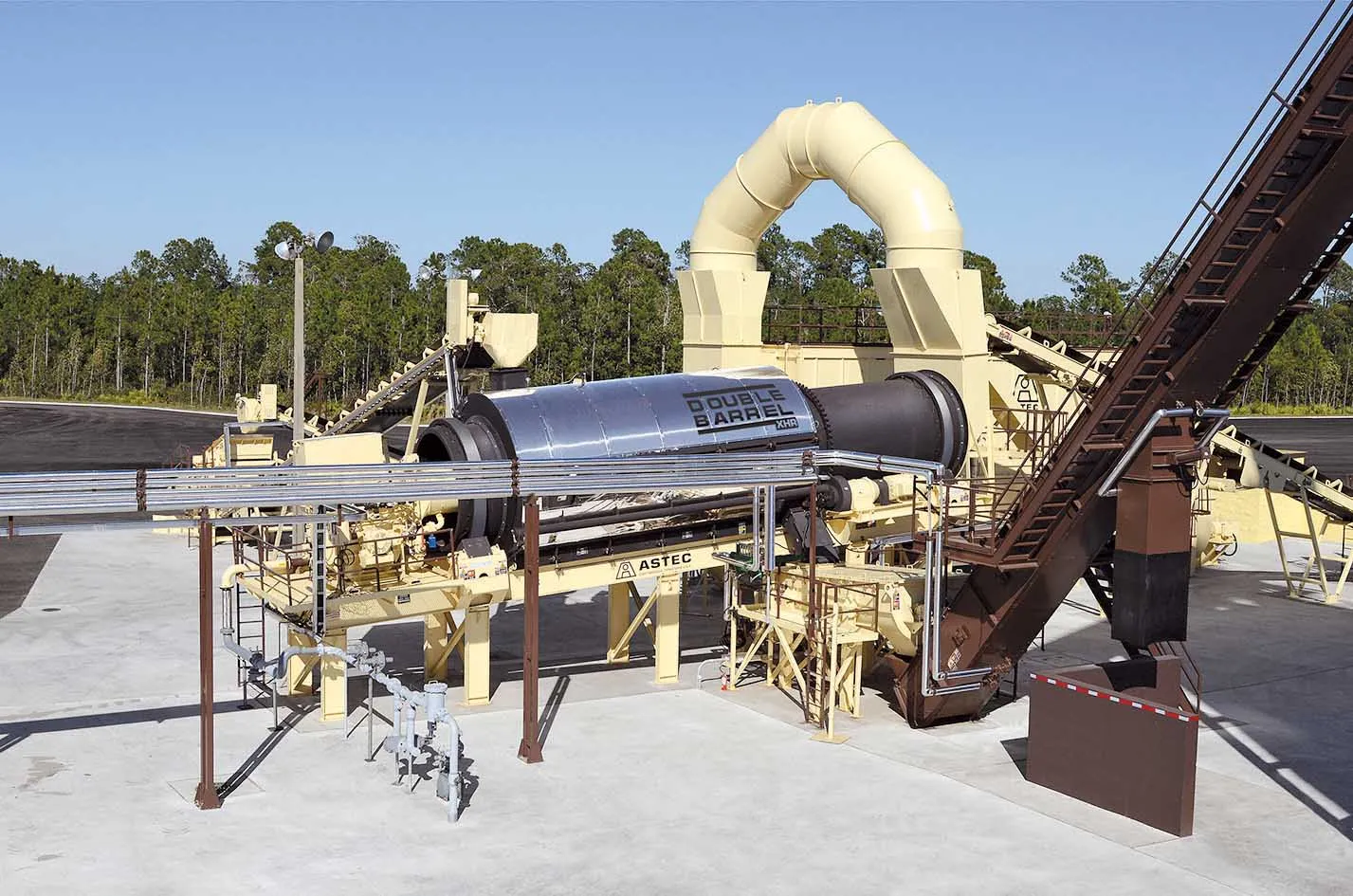

One of the key operating features is the double screen drum, which combines the drying and screening of aggregates in a single drum to deliver high levels of operating efficiency. The inclusion of the double screen drum eliminates the need for a hot elevator or vibrating screens, which helps to lower operating costs and reduce maintenance requirements.

Environmental credentials are said to be good due to a pollution control unit that includes an ambient-air cleaning system to purify exhaust gas and filter dust.

This means clean air is released into the atmosphere. Precision and quality of the asphalt mix is assured thanks to a design that includes a separate weighing system with load cells for aggregates, filler and bitumen. Customers can be assured of reliability through Linnhoff’s long-standing business model that combines German engineering with local manufacturing, using the highest quality materials and components.

Lintec & Linnhoff also launched its locally-built TSD1500 MobileMix plant from the Linnhoff brand at Excon India 2022. These units are said to appeal to customers in India due to their high mobility. A keynote feature of the design are the four fully integrated main mobile modules with built-in chassis.

The TSD1500 features a maximum capacity of 120 tonnes/hour and is designed to conform to international land transportation requirements. Only prime movers are required for quick mobilisation and demobilisation. By offering important advantages in terms of enhanced mobility, the TSD1500 is ideal for use in remote locations or short-term projects.

All units come equipped with a hydraulic power pack self-jacking system, which avoids the need for high-capacity cranes during installation and dismantling. As with the new DRX models, they also include double-screen drum technology for reduced fuel consumption and maintenance.

“We’ve designed these new units to meet the needs of Indian customers, with a strong focus on productivity, speed and ease of use,” said Lee Yen Meng, CEO at Lintec & Linnhoff Asphalt. “These asphalt mixing plants are well-suited for all types of projects, and will be a great addition to the existing population of over 400 Linnhoff asphalt plants in India.”

Manav Kohli, chief operating officer– CI, Gainwell Commosales commented, “This partnership will enable us to extend comprehensive solutions to our customers. The DRX and TSD series of asphalt plants feature fast set-up and dismantling, and each unit is manufactured at the Gainwell facility in Asansol, providing for faster delivery.”

All Linnhoff asphalt mixing plants will be sold and serviced locally in India by Gainwell Commosales.

These plants will retain the high quality of the Lintec & Linnhoff brand, while being made in India will ensure they are affordable for the local market. High asphalt mix quality is said to be achieved with the DRX and TSX plants, while the latter also offers mobility and additional versatility as a result.