Watch the video

You don’t get the name “The Dirt Ninja” without a serious obsession with all things heavy equipment and the technologies empowering what’s next for civil construction. For over a decade, Tom Gardocki, co-owner of New Era Excavation, has commanded hundreds of thousands of views on his YouTube channel—with a description that reads, "Anyone can run equipment, very few can operate.” Well said. Fact is, when Gardocki gets in a cab, he leverages iron with unrivaled precision, efficiency and swagger. Recently he got his hands on something that’s breaking new ground in the industry: Trimble Siteworks Machine Guidance. And when The Dirt Ninja put it to the test, it not only lived up to the hype—it became his personal recommendation to anyone looking to break into construction technology without breaking the bank.

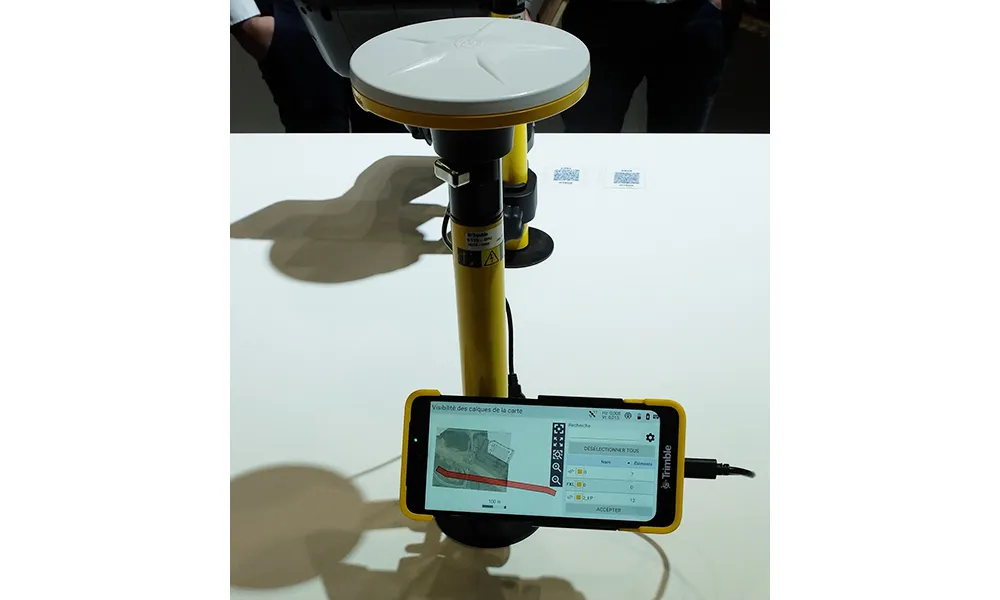

Gardocki’s firm focuses on high-end residential and small commercial grading, excavation and utility installation in Southern New Hampshire and Northern Massachusetts. New Era Excavation invested in 2D grading systems in its earliest days, and today, most of the company’s heavy machinery is equipped with 2D and even a few full 3D systems. His latest foray into technology put him in the driver’s seat of a solution, purpose built for site and utility contractors like him. The Trimble Siteworks Machine Guidance Module is a multi-purpose solution designed to perform a range of common activities with ease, including site surveys, 3D machine guidance, in-field design and reporting.

“We’re a small company - just five people - so our success is all about efficiency on the jobsite. For me, that’s where technology comes in,” says Gardocki. Demonstrating the two-in-one workflow of Trimble Siteworks, he gathers site positioning data and then effortlessly moves the receiver and display from the survey pole into the cab to measure grade and start digging. This allows him to do the work of two people, while completing it safely and without delay.

“Over the course of the year,” Gardocki explains, “(with Trimble Siteworks) we can get more jobs done. Even if we got only one more job done, that could make all the difference and have the system pay for itself.”

Watch the video

Content produced in association with Trimble