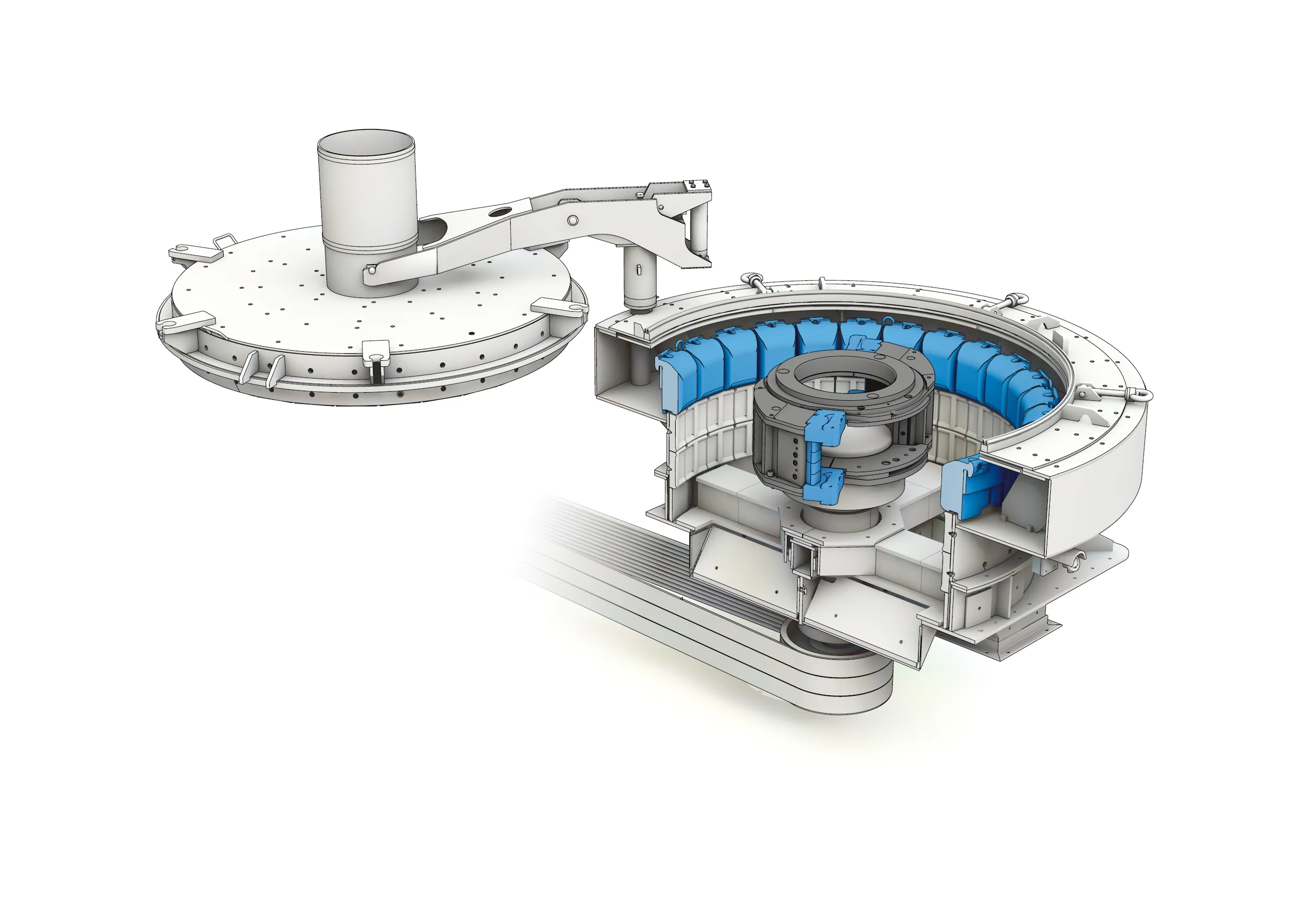

BHS-Sonthofen’s new vertical shaft impact (VSI) rotor centrifugal crusher (RSMX) offers a throughput rate of up to 580tonnes/hour, depending on the properties of the feeding material and the desired final product.

With TwinDrive for the first time (a double drive), the first delivered machine is said to have proved to be a success in the treatment of gold-containing ores.

A compact rotor with two generously dimensioned centrifugal chambers is mounted on a vertically positioned shaft in the VSI rotor c

March 11, 2016

Read time: 2 mins

With TwinDrive for the first time (a double drive), the first delivered machine is said to have proved to be a success in the treatment of gold-containing ores.

A compact rotor with two generously dimensioned centrifugal chambers is mounted on a vertically positioned shaft in the VSI rotor centrifugal crusher, and feeding material is supplied centrally from above and picked up by the two centrifugal chambers in the rotor.

Such crushers are successfully used throughout the world for crushing rock, including the treatment of abrasive ore, although many potential users require even more powerful machines for their production processes.

With its RSMX 1222, BHS-Sonthofen says it has introduced a high-end version of the VSI rotor centrifugal crusher with a drive power of up to 2 x 315kW. The first RSMX 1222, with a drive power of 2 x 250kW, was recently delivered to a goldmine near Benxi City, China, Liaoling. It processes granite with a feeding size up to 70mm into sand with grain sizes between 0-5mm and gravel with a grade between 5-20mm.

The diameter of the feeding material can range up to 120mm, depending on the type of rock.

BHS offers the option of carrying out tests with the user's rock at the company's Technology Center in Sonthofen, Germany.

All videos