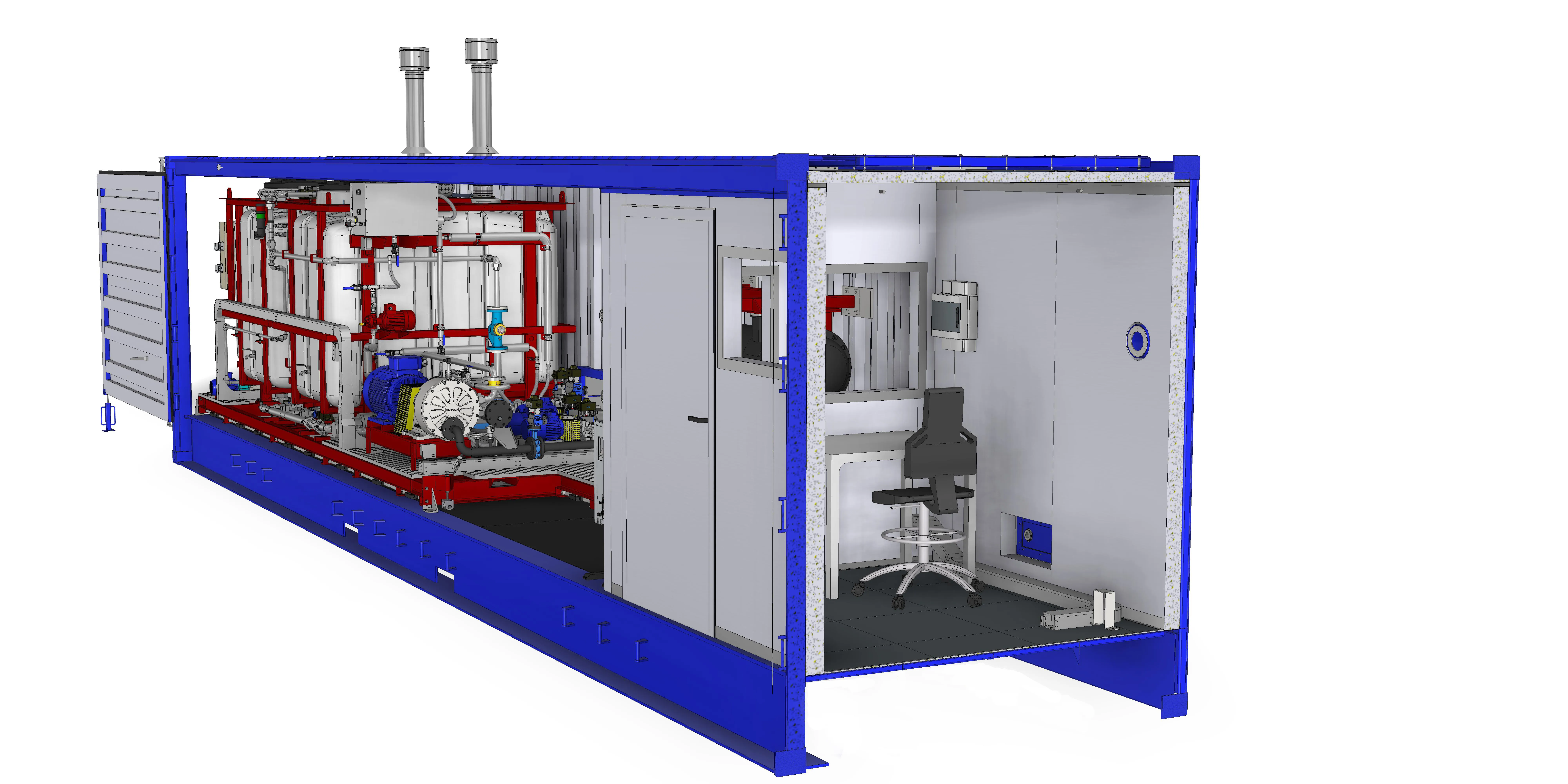

TEC Container Solutions says its 12m-long MEST Bitutainer self-contained storage container can play a pivotal role in advancing crumb rubber operations for road surfacing.

The MEST Bitutaine is tailored to improve efficiency and safety, particularly for specialty bitumens such as emulsions, PMBs and crumb rubber, which incorporates recycled rubber particles, typically from used tyres.

Frequently in road construction, seamless and efficient application of bitumen spray coat is a fundamental part of the project. Yet, traditional logistics and storage solutions have long posed challenges, leading to increased costs and delays. TEC Container Solutions says that its MEST Bitutainer was created to revolutionise spray coat logistics in road construction.

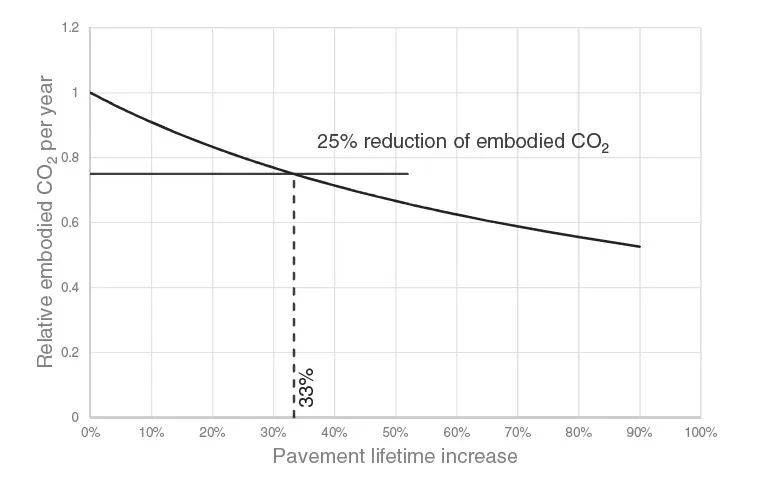

Crumb rubber bitumen offers superior durability, resistance to deformation, and improved lifespan compared to conventional bitumen, making it an ideal choice for road construction and maintenance. Crumb rubber bitumen has been shown to be more resistant to cracking and rutting, extending the lifespan of road surfaces. By recycling used tyres, crumb rubber reduces landfill waste and promotes sustainable practices. As well, roads paved with crumb rubber bitumen exhibit lower noise levels, enhancing driving comfort.

The MEST unit has integrated monitoring and control technology to maintain optimal conditions for the bitumen. The MEST Bitutainer is equipped with a built-in pipework manifold system for filling, discharging and recirculating bitumen, making it a versatile solution for various bitumen types, such as crumb rubber.

Key features of the MEST Bitutainer include a bottom-mounted screw agitation system. This ensures that the crumb remains evenly distributed and suspended throughout the bitumen to maintain optimal properties of the solution.

The unit’s monitoring and control technology complies with the rigorous AS Standards of both Australia and New Zealand. The well-insulated interior and efficient electric element heating system reduce operational costs associated with bitumen storage, making the MEST Bitutainer a cost-effective solution for crumb rubber operations.

Safety, meanwhile, is paramount and TEC Container says its MEST Bitutainer exceeds traditional safety requirements because of its a secondary containment wall. This eliminates the need for additional costly bund walls.

TEC Container Solutions also supplies containers for vacuum residue and fuel oils such as crude, diesel, HFO and more.

For more information, visit the TEC Container Solutions website.