“Having five screens as standard means that customers can have much more flexibility in the recipes they produce,” said Henrich.

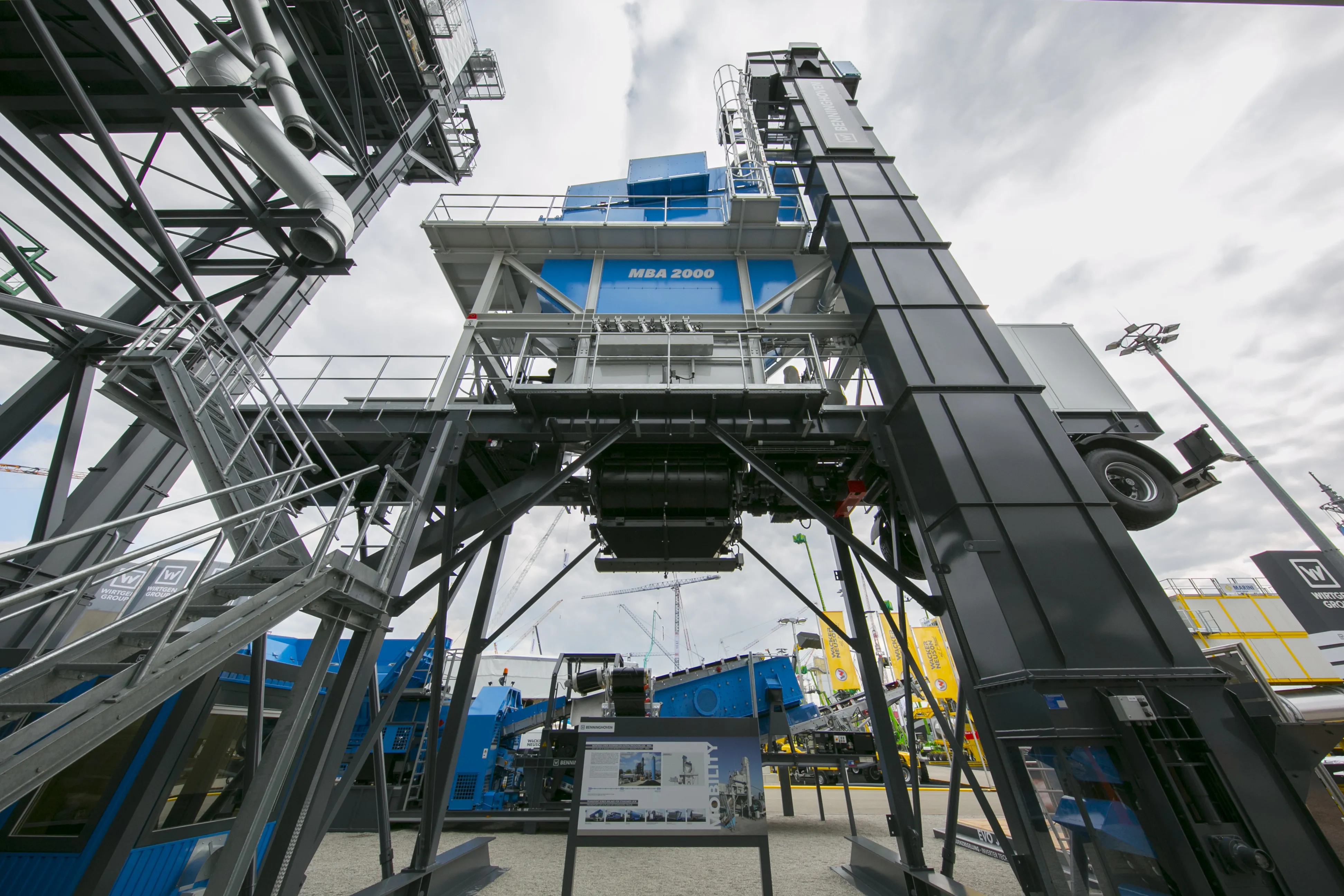

Designed for ease and speed of erection and dismantling, the MBA plants are mounted on mobile steel foundations. They have been sized so that standard trailers can transport them, avoiding the time and inconvenience of arranging any special approvals.

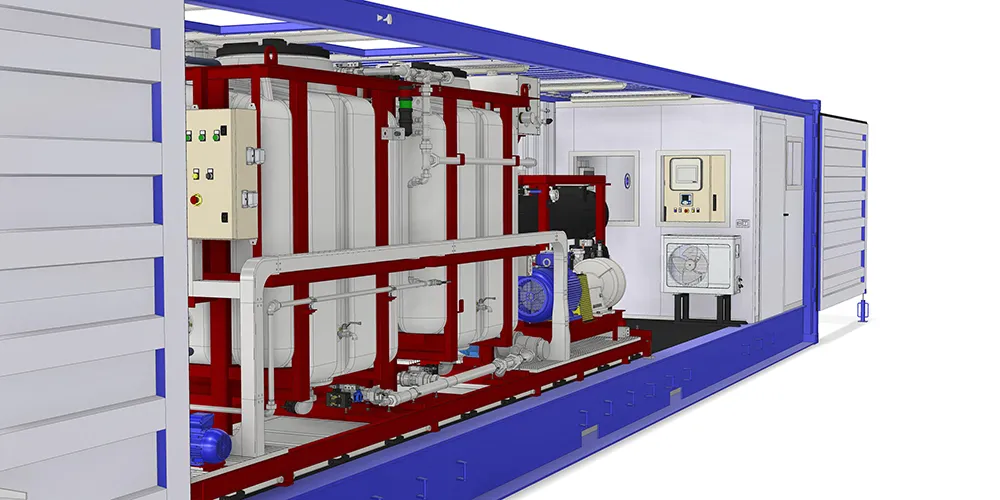

Mobile plants, together with containerised plants, are Benninghoven’s most popular products, a trend that Henrich predicts will continue as countries around the world create new road infrastructure. “At the moment we are selling plants to countries in Eastern Europe, to Turkey and Russia. But in the future, we expect to supply them to countries around the world,” he said.