Combining latest engine and drivetrain technology with specific Bell innovations, the 28-tonne B30E and 24-tonne B25E ADTs are said to redefine the standards in productivity, safety and drivers’ comfort for earthmoving and smaller quarrying applications.

“When introducing our new E- Series into the international markets two years ago, we opted for our proven ‘Blu@dvantage’ emission control technology, using Selective Catalytic Reduction (SCR) to meet the transitional Stage IIIB/Tier 4i standards. This approach, with our vehicle’s performance and fuel consumption as the main motivation, was certainly the right decision seeing the successful acceptance of our small trucks in all respective European and American markets,” said Tristan du Pisanie, Bell Equipment's ADT product marketing manager.

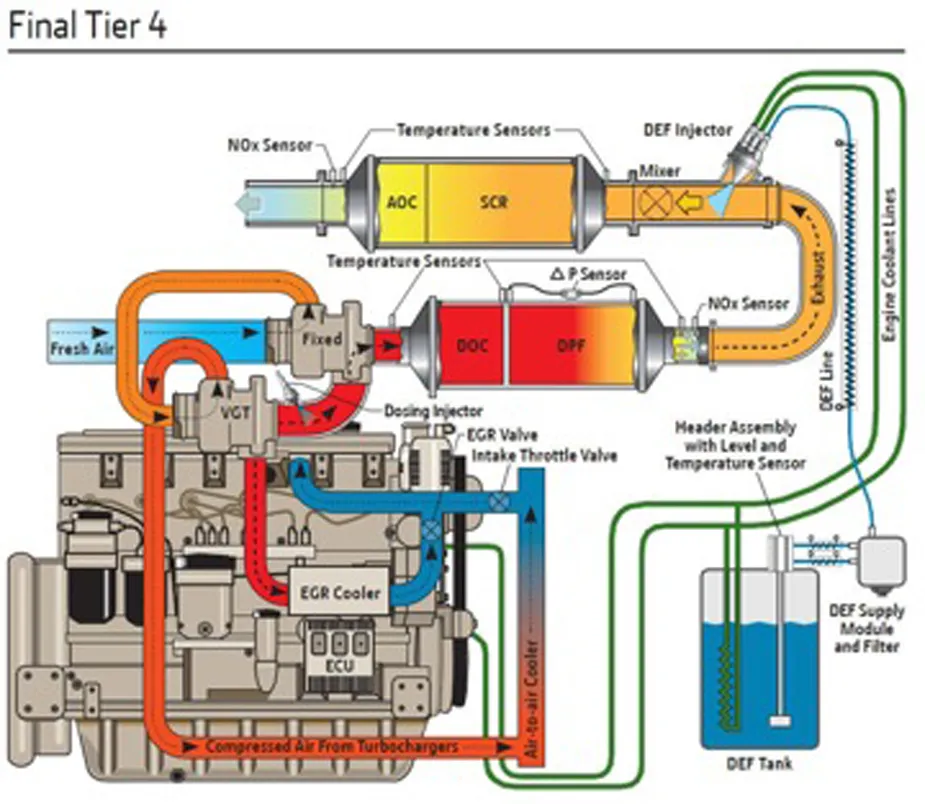

The new generations of Bell B25E and B30E are now both powered by the 7.7litre engine, OM936LA, from Mercedes-Benz. The inline-6-cylinder is an EGR engine with minimal re-circulation of cooled exhaust gas into the combustion process. This, in combination with the urea-based SCR after treatment system (Adblue/DEF), is said to ensure efficient emission control without the need for diesel particulate filters (DPF).

The new engine is also claimed to improve the performance of the trucks, with both B25E and B30E featuring Allison transmissions and lockable inter-axle differentials/limited slip axle differentials - the identical drivetrain components of their Stage IIIB / Tier4i predecessors.

Production of the Stage IV / Tier4f compliant models of B25E and B30E started in January 2015 at Bell Equipment’s European ADT plant in Eisenach, Germany. Following the company's commitment to continuous development of its products, the new generation also incorporates improvements in thermal/noise insulation of the cab and new ergonomic features and other small improvements thanks to feedback from customers and dealers.