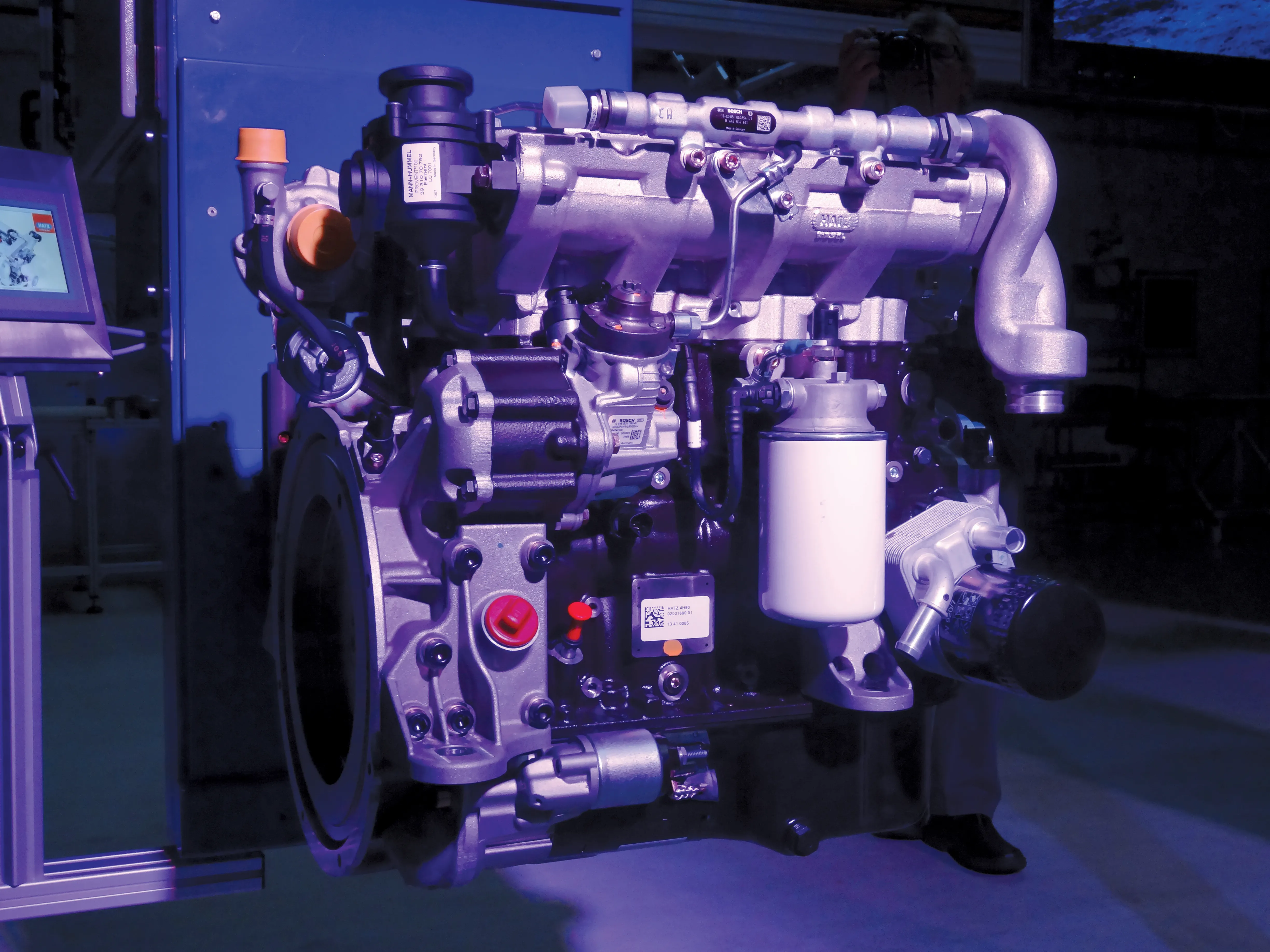

BBA Pumps has launched a new line-up of dewatering pumps. The company says that the main focus went into the reduction of the carbon footprint, with all units standardised on the cleanest highly-regulated diesel engines to comply with stringent European emission legislations. The pumps are designated BA100K (4” unit); BA180E (8”) and BA300E (12”).

The BA100K, driven by single cylinder Hatz with a DPF module, can pump 190m³/hour and has a maximum head of 22mwc (metre water column).

The next in line, th

March 16, 2016

Read time: 2 mins

The company says that the main focus went into the reduction of the carbon footprint, with all units standardised on the cleanest highly-regulated diesel engines to comply with stringent European emission legislations.

The pumps are designated BA100K (4” unit); BA180E (8”) and BA300E (12”).

The BA100K, driven by single cylinder Hatz with a DPF module, can pump 190m³/hour and has a maximum head of 22mwc (metre water column).

The next in line, the BA180E, can handle 720m³/hour and has a maximum head of 41mwc, while the BA300E’s 1,250m³/hour pumping capacity and maximum head of 19mwc is achieved, as with the BA180E, using a new

“We received frequent requests for a more compact 12” waste water pump, this is because of the limited space available in urban areas for sewer by-pass jobs.” says Henno Schothorst, product manager at BBA Pumps.

“That’s why we are proud of this entirely new BA300E development. Compared to the previous model it is now much easier to deploy for waste water projects.”