Since the Stage IIIB emissions standards went into effect in Janauary 2011 throughout most of Europe, portable compressor manufacturers have developed different technologies to comply with the directives. With its latest DrillAir order, the Norwegian drilling company Båsum Boring was the first to purchase a Stage IIIB-compliant Atlas Copco compressor. “We have been using Atlas Copco compressors for years and we like their reliability and service level. For Stage IIIB machines, we looked at other suppliers,

June 24, 2013

Read time: 2 mins

Since the Stage IIIB emissions standards went into effect in Janauary 2011 throughout most of Europe, portable compressor manufacturers have developed different technologies to comply with the directives. With its latest DrillAir order, the Norwegian drilling company Båsum Boring was the first to purchase a Stage IIIB-compliant 161 Atlas Copco compressor.

“We have been using Atlas Copco compressors for years and we like their reliability and service level. For Stage IIIB machines, we looked at other suppliers, but they didn’t offer us the same quality, performance and aftersales service and spare parts,” said Båsum Boring’s Nils Hanstad.

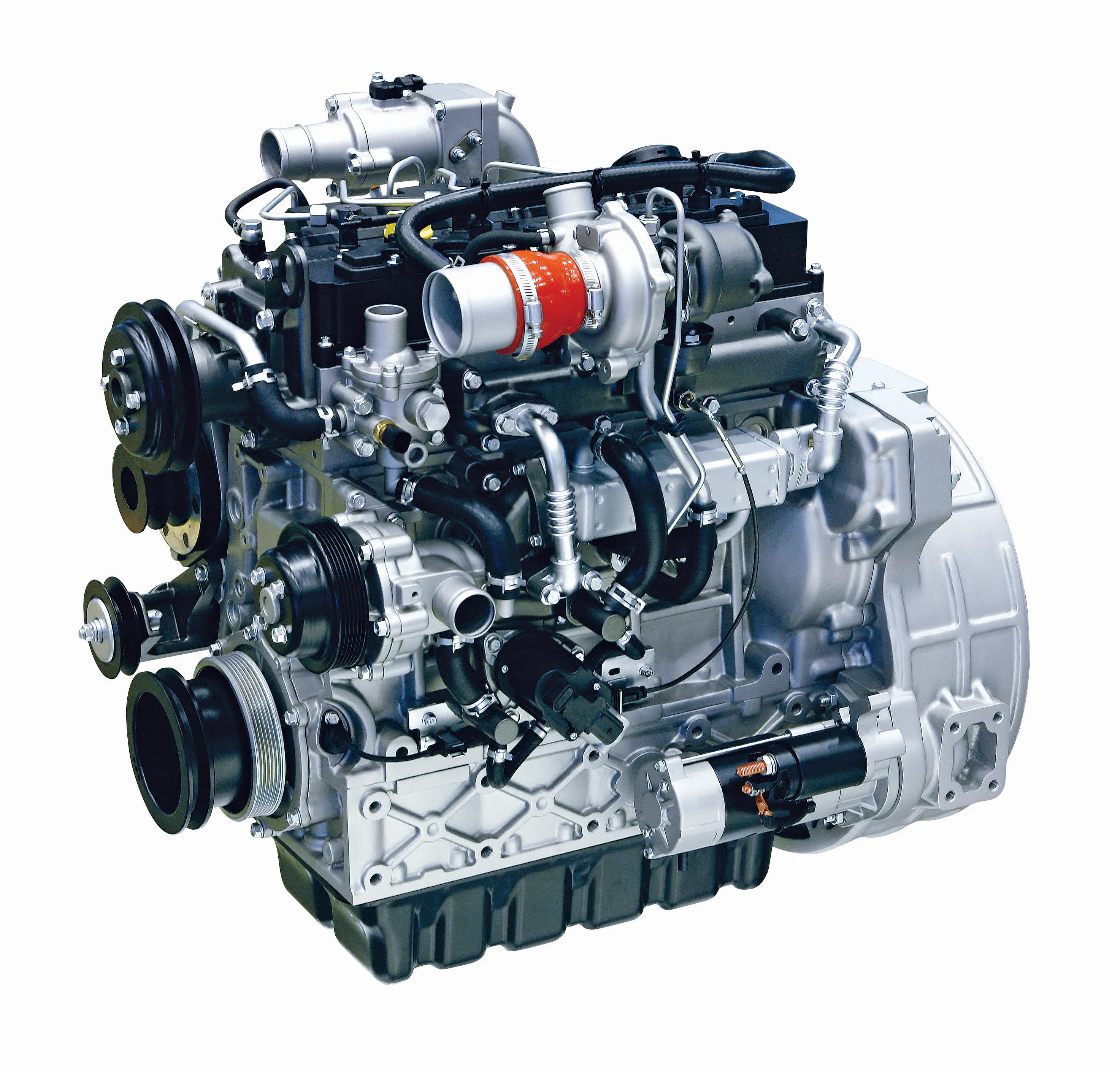

The new Stage IIIB legislation for 130-560kW off-road diesel engines aims to improve air quality through a decrease in the discharges of particulate matter by no less than 90% and nitrogen oxides (NOx) by 50%. In 2014, even more stringent legislation will require particulate matter and NOx levels to be reduced to near zero for almost all power categories. In the meantime, Stage IIIA units can be sold in Europe as long as 2010 stock or flexibility allowance lasts.

This leaves rental, construction and mining companies with important operational and financial considerations related to how to deal with Stages IIIB and IV and the transition period in between. Headquartered in Oslo, Båsum Boring will be using its Stage IIIB DrillAir from Atlas Copco for energy drilling of up to 400m.

“We have been using Atlas Copco compressors for years and we like their reliability and service level. For Stage IIIB machines, we looked at other suppliers, but they didn’t offer us the same quality, performance and aftersales service and spare parts,” said Båsum Boring’s Nils Hanstad.

The new Stage IIIB legislation for 130-560kW off-road diesel engines aims to improve air quality through a decrease in the discharges of particulate matter by no less than 90% and nitrogen oxides (NOx) by 50%. In 2014, even more stringent legislation will require particulate matter and NOx levels to be reduced to near zero for almost all power categories. In the meantime, Stage IIIA units can be sold in Europe as long as 2010 stock or flexibility allowance lasts.

This leaves rental, construction and mining companies with important operational and financial considerations related to how to deal with Stages IIIB and IV and the transition period in between. Headquartered in Oslo, Båsum Boring will be using its Stage IIIB DrillAir from Atlas Copco for energy drilling of up to 400m.