Atlas Copco’s (AC) ergonomically designed LP6500 duplex roller is said by the Swedish firm to offer high operator comfort. The claim is said by AC to be supported by a recent test by the independent technical inspection organisation TÜV Nord, in which the LP6500 was compared with two similar duplex roller models from other manufacturers. The test is said to have confirmed that the LP6500 has lower vibrations in the handle and lower machine noise than similar machines, resulting in considerably less strain o

January 20, 2014

Read time: 2 mins

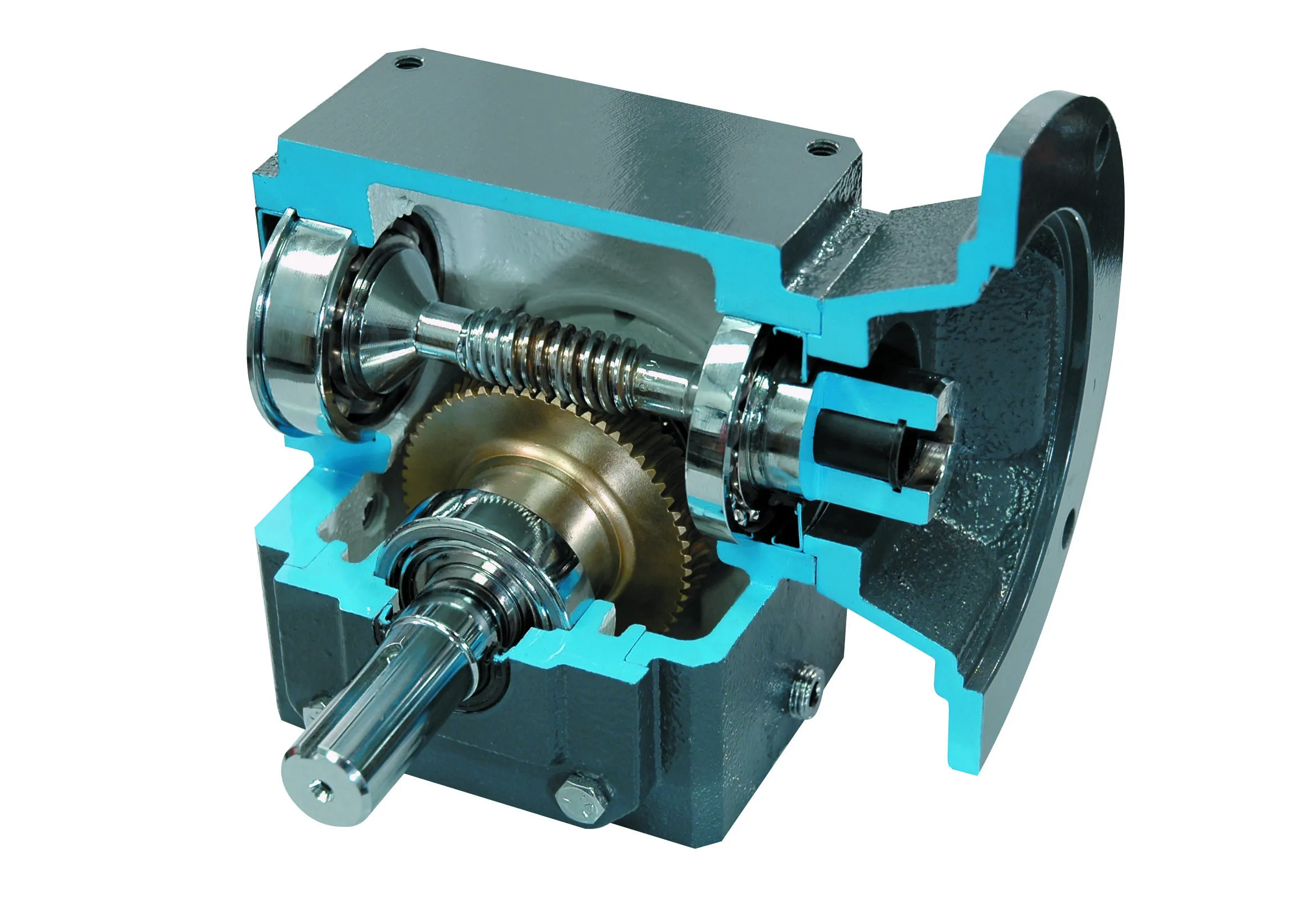

The LP6500’s hydraulic transmission is said to eliminate the need for chains or gears and supports a compact machine design with smooth sides, high curb clearance and no overhang. This is said by AC to make handling the LP6500 close to obstacles or edges easy.

The LP6500 is also equipped with a controlled cooling fan to help reduce the risk of unplanned stops. This can contribute to longer operation times, longer service intervals and prolonged machine lifetime.

With its 6.8kW engine, the LP6500’s power and speed is said to ensure high compaction efficiency and reduces the time required to perform each task.

To simplify maintenance, there is an hour meter and an oil alert as standard. A rigid protection frame, with a single lifting point for easy transportation, lessens the risk of impact damage. The large corrosion-free water tank reduces the number of refill stops and serves as protection for the cooling fan.

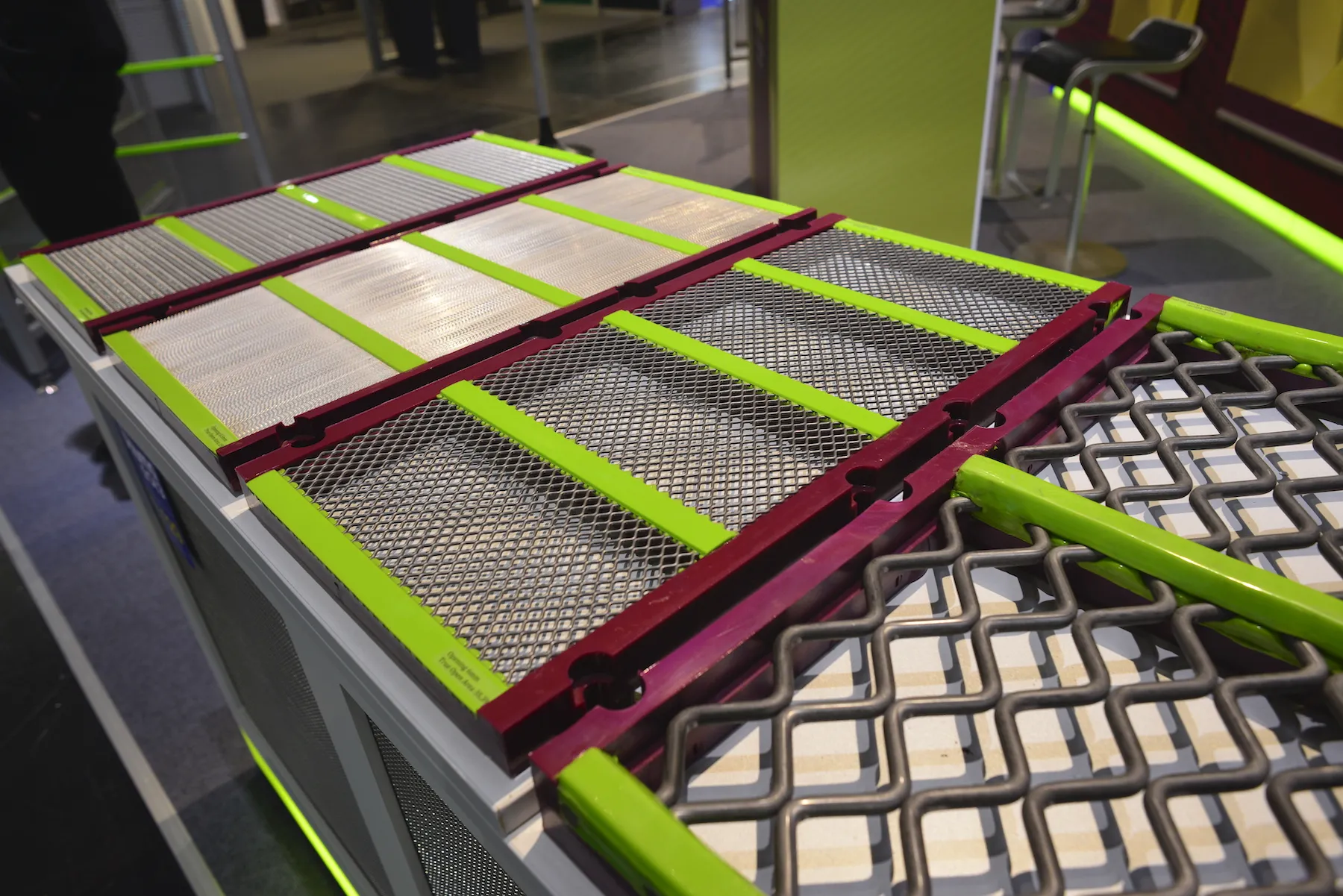

Achieving high compaction efficiency on granular soil layers, such as sand and gravel, when compacting silt the compaction effect depends largely on water content and the LP6500 is most effective on thin layers. On asphalt the end results are said by AC to be excellent, and the LP6500 is well suited for smaller jobs in areas such as pavement construction or repair, narrow roads, playgrounds or parking lots.

%$Linker: