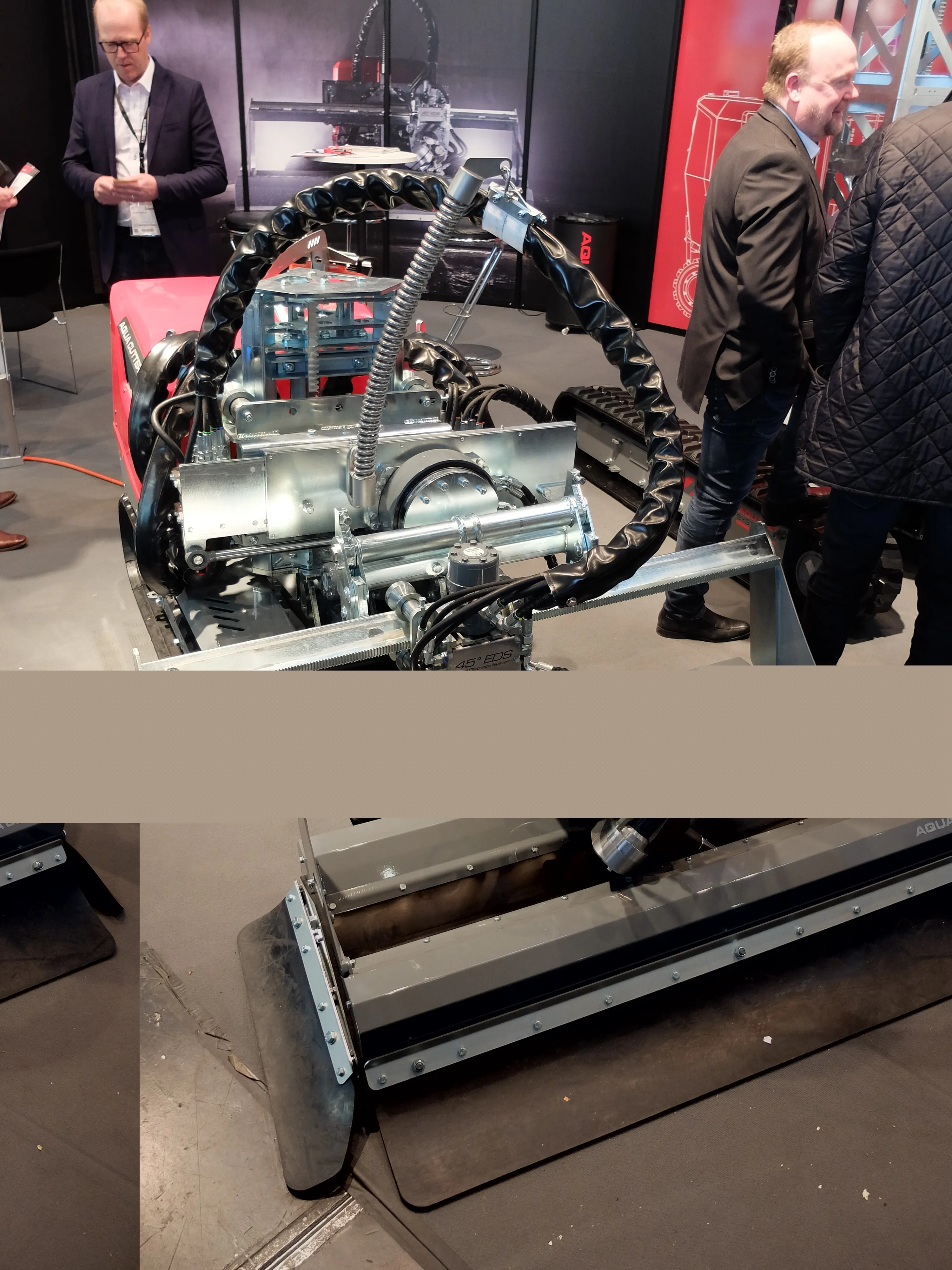

Aquajet is increasing the capabilities of its range with the new 410V Evolution and 710V Evolution XL machines. Key account manager Patrik Anderson explained, “We have upgraded the front of the 410V so you can do more work, as with the 710V. You can do work now directly on walls. It has a reach of 4m and we use the Aqua Spine solution for the tower.”

He continued, “The 710 XL is built with a wider and longer chassis and can take even more reaction force. Due to the bigger chassis you have a lower ground pr

April 19, 2016

Read time: 2 mins

He continued, “The 710 XL is built with a wider and longer chassis and can take even more reaction force. Due to the bigger chassis you have a lower ground pressure as you have a larger footprint.”

Also new from the firm is its improved aftertreatment unit, the Evoclear. This fits into a standard shipping container allowing it to be transported more easily. Anderson said that the unit is designed to take proper care of the water after use in the hydrodemolition process and has a system designed to regulate the pH balance automatically. This improved unit also offers greater throughput and has a capacity of 20m3/hour.

All videos