“What’s different about our plant is that all of it fits in certified shipping containers,” said Amomatic’s Michael Gardias, sales and business development, Africa. “That means they are treated as standard containers, not special items so the transportation costs are reduced significantly, particularly if they are travelling a long way either by sea or inland.”

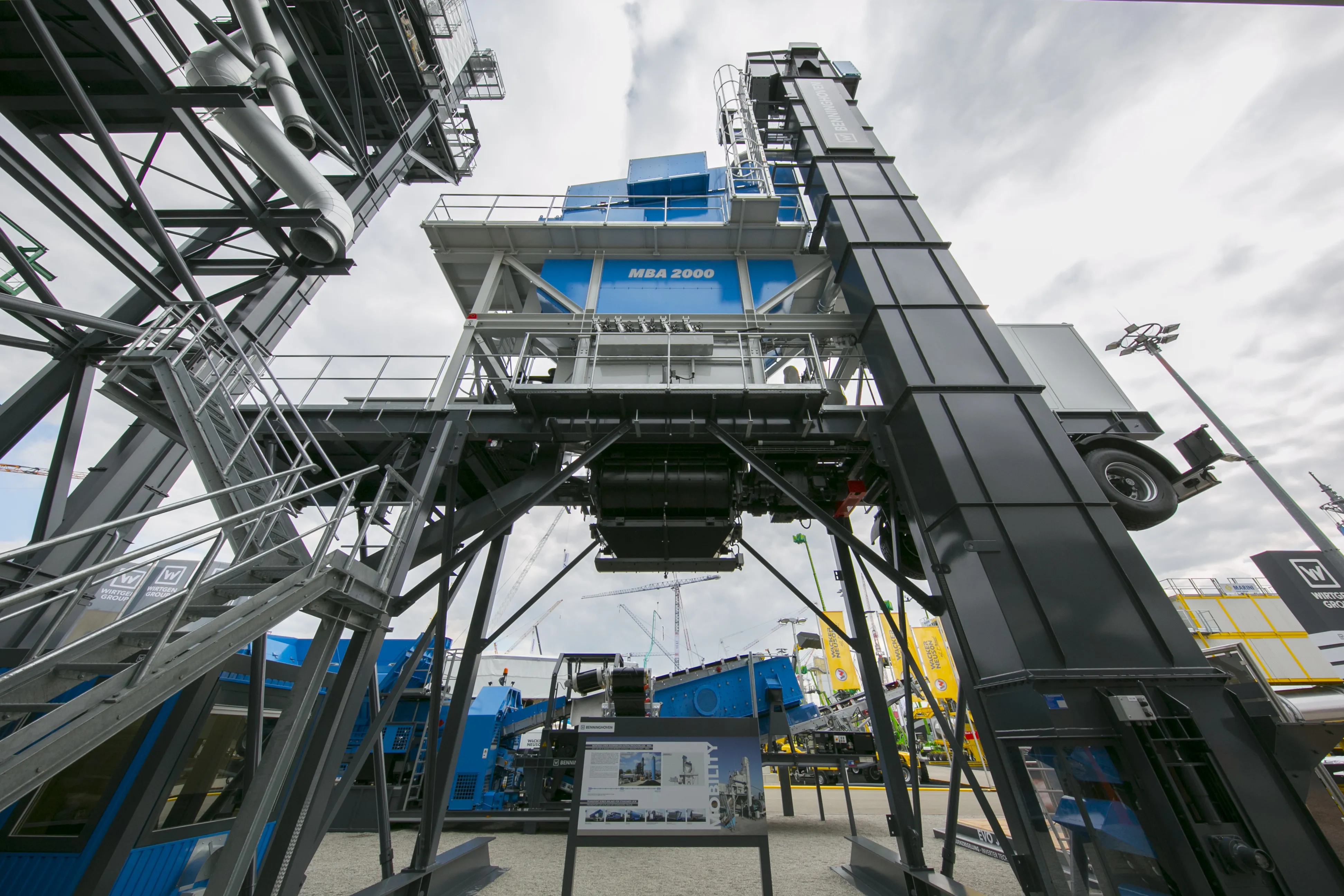

The plant on show at bauma is the 160 CM. Amomatic first trialled the approach on its 120 tonne per hour plant which was supplied to a customer in Norway to a site accessible by small mountain roads. Clever modifications from the standard include vertical rather than horizontal silos, said Gardias.

Gardias predicts that the containerised plants will take over from Amomatic’s standard ones. “When people customise the plant, they often have to make compromises but we have managed not to do that,” said Gardias.

Amomatic has designed the plant for speed and ease of erection. According to Gardias a crew of two workers and one mobile crane erected the tower for the BAUMA stand. “It’s a bit like a lego asphalt plant,” said Gardias. “It’s easy to move if a customer wants to move production: one day to take it down, time to transport and then one day to put it up again.”

Amomatic’s original target market was emerging markets such as Africa and the Middle East. However at bauma, there has been interest from people from a variety of European countries and Russia, said Gardias. “We are here at bauma to look for new markets,” he said.