Because it comes in containers, transport and set-up costs are reduced while Ammann says this is without compromising performance, quality or flexibility.

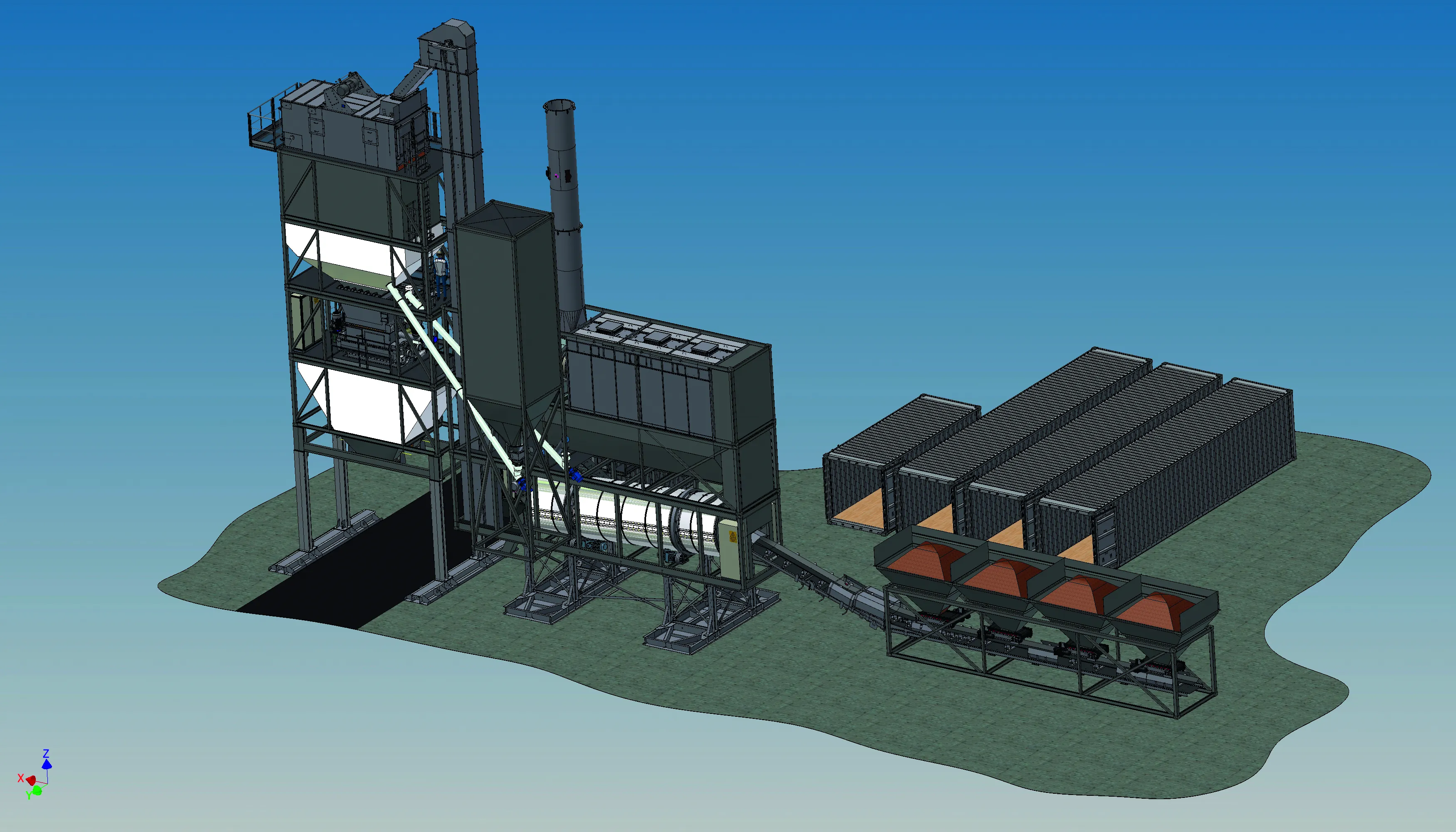

The plant delivers high output despite its compact dimensions as well as a high asphalt mix quality. All the dryer/filter units and mixing tower modules come in containers. In addition, all the add-on components, such as the cold feed and the control cab fit in standard containers. The QuickBatch is available with outputs of up to 140tonnes/hour and 180tonnes/hour and the firm says the plant offers the advantages of a stationary mixing plant, but is designed for international operation involving frequent moves for use at different locations.

Transportation infrastructure is geared towards container transport, so the design of this plant helps cut costs when moving it from site to site when this is over large distances, or even internationally. The individual components are placed in containers module by module. All the electrical and mechanical interfaces are pluggable to considerably reduce the time and cost of installation. The QuickBatch is said to offer all the functions and options of conventional plants and can be equipped with Ammann’s range of recycling solutions. The plant features five or six hot aggregate silos of 18m3 capacity, the firm’s 1.7tonne capacity QuickBatch 140 or 2.2tonne capacity QuickBatch 180 mixers and four cold feed bins as a standard, as well as the as1 control system.