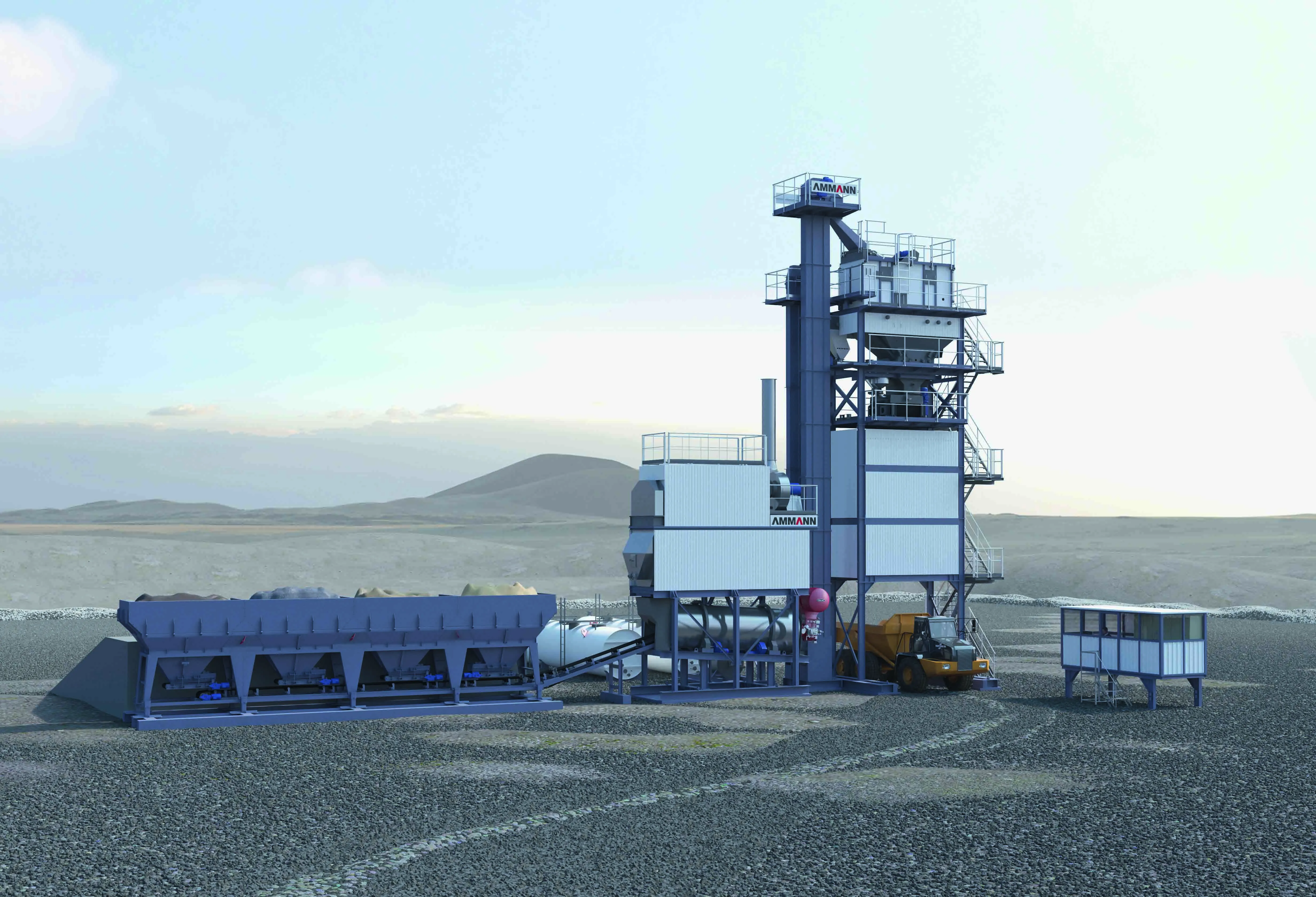

Ammann has been developing continuous asphalt plant technology for the North American market. The firm has been utilising technology developed for its European batching plants and compact continuous plants in the project to develop a large capacity asphalt plant for North America.

The product from this development programme is the firm’s ACC Alpine plant, with the first unit being supplied to a customer in Florida. The ACC Alpine plant is offered with a wide range of options, in stationary and portable format and with a choice of capacities of 300, 400, 500 and 600tonnes/hour. Customers can select different material feeds, reverse air or pulsed baghouses, electrically-heated tanks and silos of 100, 150, 200, 250 or 300tonne capacity. The plant can use up to 50% RAP with a single feed or up to 60% with a twin feed system, while it can also be used to produce warm mix or mixes containing crumb rubber (as used in Arizona and New Mexico in particular).

At the moment, the plant is being fitted with a bought-in burner system but Ammann is developing its own burner design for use with this high capacity continuous plant.