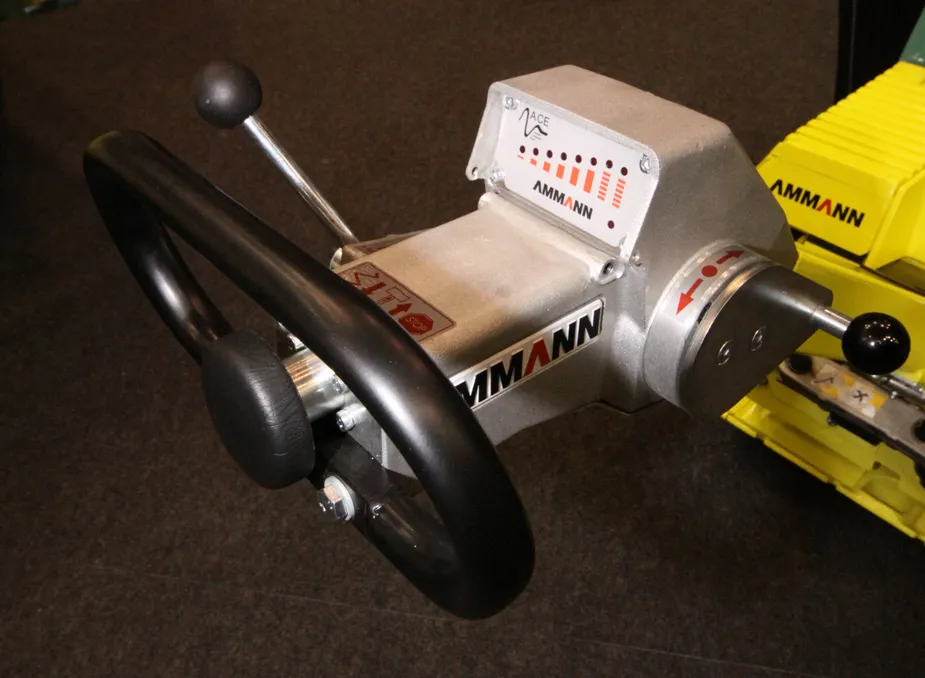

Launched at bauma 2013, Ammann claims its Rammax 1575 CI trench roller at ConExpo 2014 has set new standards with regard to safety, technology and emissions.

The model’s water-cooled diesel engine from Yanmar is said to be a guarantor for reliability, low noise generation and low fuel consumption and is fully compliant with the latest emission standards. The pendulum function of the articulated joint enables the machine to adapt to the substrate and is said by Ammann to ensure outstanding compaction result

January 20, 2014

Read time: 2 mins

Launched at 688 Bauma 2013, 6791 Ammann claims its Rammax 1575 CI trench roller at Conexpo 2014 has set new standards with regard to safety, technology and emissions.

The model’s water-cooled diesel engine from7139 Yanmar is said to be a guarantor for reliability, low noise generation and low fuel consumption and is fully compliant with the latest emission standards. The pendulum function of the articulated joint enables the machine to adapt to the substrate and is said by Ammann to ensure outstanding compaction results in applications including trench and pipeline construction, backfilling for bridges and other structures, trench filling, embankment and landfill construction, and base construction for roads and rail tracks.

The maintenance-free articulated pendulum joint on the Rammax 1575 CI is said to guarantee that all four drums remain in permanent contact with the substrate for ideal traction and compaction; in conjunction with the low centre of gravity it also increases stability against tipping.

Proven infrared technology is said to ensure a high degree of safety for both man and Rammax 1575 CI machine. Solar cells integrated in the remote control ensure the model is always ready for operation. Twilight is said by Ammann to be sufficient for charging.

For the American market, Ammann is distributing its compaction products through well-established OEM partners.

%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 56240 0 oLinkExternal www.Ammann-Group.com Ammann Group Web false /EasySiteWeb/GatewayLink.aspx?alId=56240 false false %>

The model’s water-cooled diesel engine from

The maintenance-free articulated pendulum joint on the Rammax 1575 CI is said to guarantee that all four drums remain in permanent contact with the substrate for ideal traction and compaction; in conjunction with the low centre of gravity it also increases stability against tipping.

Proven infrared technology is said to ensure a high degree of safety for both man and Rammax 1575 CI machine. Solar cells integrated in the remote control ensure the model is always ready for operation. Twilight is said by Ammann to be sufficient for charging.

For the American market, Ammann is distributing its compaction products through well-established OEM partners.

%$Linker: