The completely redesigned Ammann ARX generation light tandem rollers on show at Conexpo 2014 are specifically made to compact asphalt and substrates on smaller and medium-sized building sites. The ARX 16 K, ARX 26 and ARX 45 models on show in Las Vegas are among 13 different ARX models in weight categories from 1.5 to 4.8 tonnes, with working widths from 82cm to 138cm.

January 6, 2017

Read time: 2 mins

The completely redesigned 6791 Ammann ARX generation light tandem rollers on show at Conexpo 2014 are specifically made to compact asphalt and substrates on smaller and medium-sized building sites. The ARX 16 K, ARX 26 and ARX 45 models on show in Las Vegas are among 13 different ARX models in weight categories from 1.5 to 4.8 tonnes, with working widths from 82cm to 138cm.

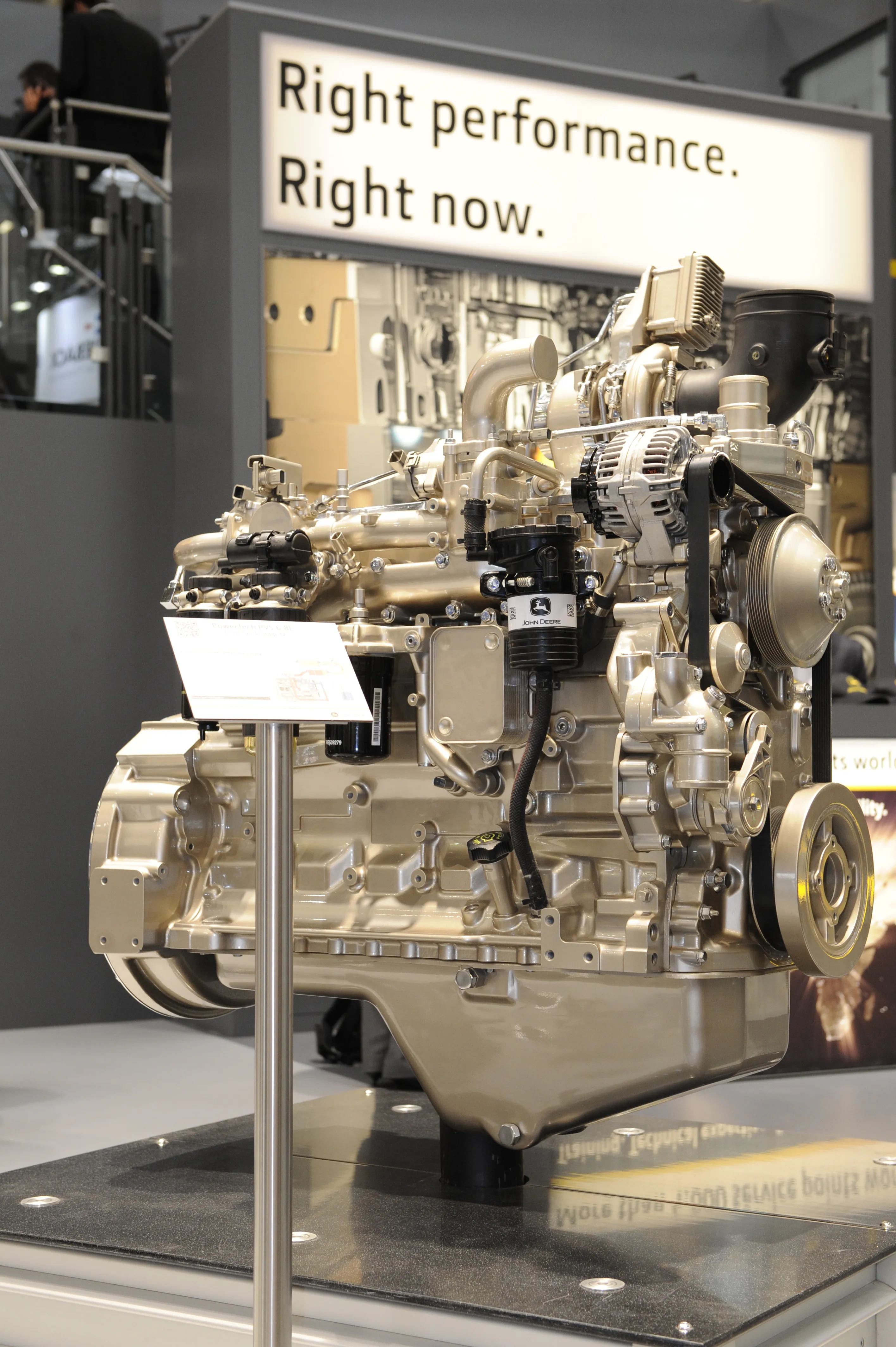

All the ARX models feature tried-and-tested technologies, such as the high-performance vibration system said to have proven its merits over the years; another example is the newly designed and highly efficient hydraulic system, which is powered by cutting-edge7139 Yanmar diesel engine technology to guarantee maximum reliability, economical consumption and compliance with the strict emission requirements in Europe and the US. The new hydraulic concept greatly increases the efficiency of the powertrain, enabling the diesel engine to be operated at significantly lower speeds – which in turn has the effect of reducing fuel consumption and engine noise.

The ARX 45 is Ammann's response to the market's requirement for a vibratory roller in the 5tonne class for asphalting on midsize construction sites.

The articulated steering on the ARX models is fitted with Teflon-coated gliding bearings. This feature is said to eliminate the need for manual relubrication throughout the machine's lifetime, thereby cutting maintenance costs and standstill times.

ARX vibratory rollers are equipped as standard with the AVC (Ammann Vibration Control) system, which automatically prevents vibration when the machine is immobile, and compaction at excessive speeds. In this way, the AVC system is claimed by Ammann to guarantee asphalting of homogeneous quality. Electric drive control via the drive lever is said to feature for the first time on rollers of this class: sensitive application and release of the Brake prevents the roller from pushing creases into the hot asphalt, and also avoids the formation of cracks.

Ammann will also be showcasing the ASC 110 single drum roller during Conexpo 2014.

%$Linker:2 Asset <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 56240 0 oLinkExternal www.ammann-group.com Ammann Group Website false /EasySiteWeb/GatewayLink.aspx?alId=56240 false false %>

All the ARX models feature tried-and-tested technologies, such as the high-performance vibration system said to have proven its merits over the years; another example is the newly designed and highly efficient hydraulic system, which is powered by cutting-edge

The ARX 45 is Ammann's response to the market's requirement for a vibratory roller in the 5tonne class for asphalting on midsize construction sites.

The articulated steering on the ARX models is fitted with Teflon-coated gliding bearings. This feature is said to eliminate the need for manual relubrication throughout the machine's lifetime, thereby cutting maintenance costs and standstill times.

ARX vibratory rollers are equipped as standard with the AVC (Ammann Vibration Control) system, which automatically prevents vibration when the machine is immobile, and compaction at excessive speeds. In this way, the AVC system is claimed by Ammann to guarantee asphalting of homogeneous quality. Electric drive control via the drive lever is said to feature for the first time on rollers of this class: sensitive application and release of the Brake prevents the roller from pushing creases into the hot asphalt, and also avoids the formation of cracks.

Ammann will also be showcasing the ASC 110 single drum roller during Conexpo 2014.

%$Linker: