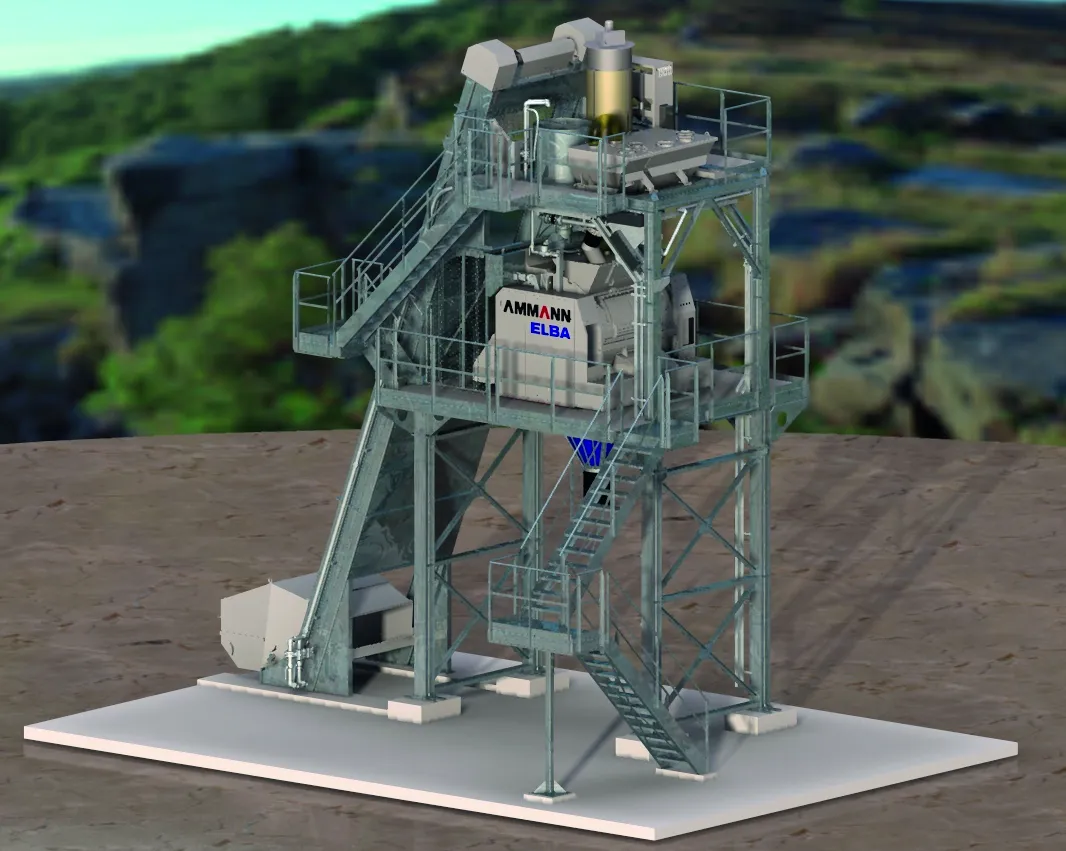

The design retains Elba’s proven layout with skip and belt elevation in the same design concept and assembly as a stationary or semi-mobile mixing plant. All drive systems and safety features comply with the latest standards and energy directives. Pre-installed modules are said to make it easy to achieve short assembly times and cost-effective transportation.

Emission values are reduced to a minimum in plants equipped with a mixer dust abatement system. Daily operations are made easier by good accessibility and spacious maintenance and cleaning platforms. The semi-galvanised design of the new Elba Concrete Centre further add to its durability. Plant output ranges from 105-200m3/hour for the range and the machines are offered with mixer sizes from the EMS 2000-2500. Aggregate storage ranges from 70-312m3, with aggregate types from 2-12, as well as six connections for cement weighing. A versatile plant layout is offered along with an optional foundation-free system design. The modular design reduces transport costs and the plant is offered with effective dust controls as well as optional feeds for additives or special products.