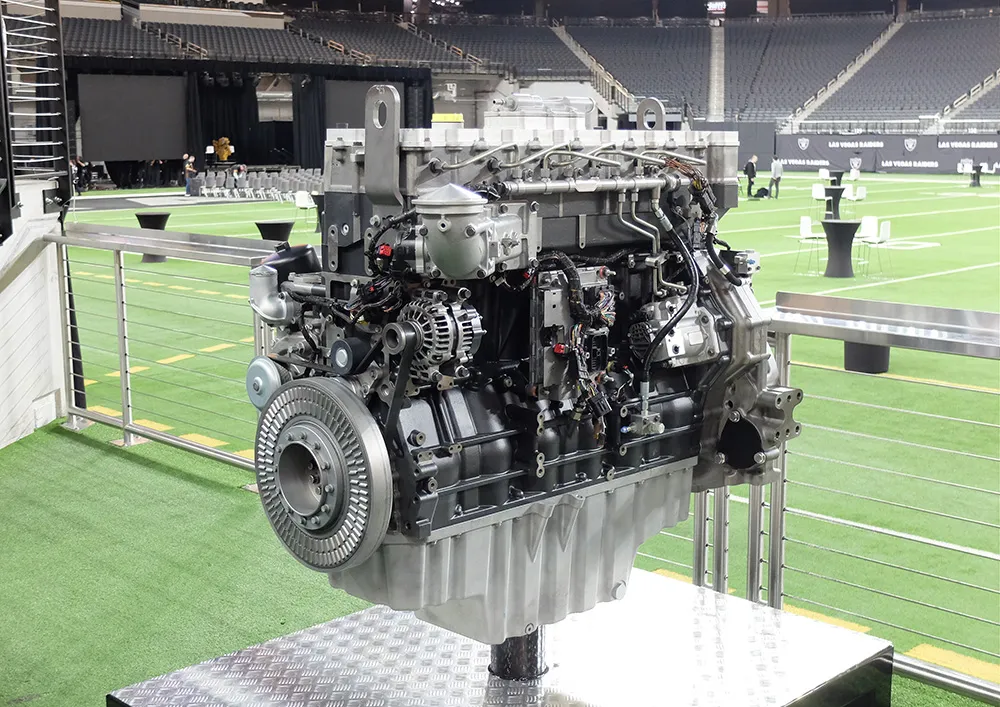

The new Prime 100 mobile asphalt plant from Ammann is designed for high mobility. This continuous plant can deliver 100tonnes/hour and features all of its main components inside a single standard shipping container. A company spokesperson said, “All you have to do is connect the bitumen tank and an electric power source.”

The new Prime 100 unit is the latest addition to the Prime range and is a smaller and even more mobile version of the well proven Prime 140, with its 140tonnes/hour capacity. In addition

January 6, 2017

Read time: 2 mins

The new Prime 100 mobile asphalt plant from 6791 Ammann is designed for high mobility. This continuous plant can deliver 100tonnes/hour and features all of its main components inside a single standard shipping container. A company spokesperson said, “All you have to do is connect the bitumen tank and an electric power source.”

The new Prime 100 unit is the latest addition to the Prime range and is a smaller and even more mobile version of the well proven Prime 140, with its 140tonnes/hour capacity. In addition to its exceptional mobility the Prime 100 is very compact when assembled, while it takes around one working day to commission once it arrives onsite. The firm has designed the plant so that it can be set up quickly with only a minimum of site preparation needed. The spokesperson said, “As long as the base has been compacted, it can operate. The plant has everything it needs.”

Despite being smaller than the existing Prime 140, the new Prime 100 plant still features high-quality Ammann core components for high performance and a quality output.

The new Prime 100 unit is the latest addition to the Prime range and is a smaller and even more mobile version of the well proven Prime 140, with its 140tonnes/hour capacity. In addition to its exceptional mobility the Prime 100 is very compact when assembled, while it takes around one working day to commission once it arrives onsite. The firm has designed the plant so that it can be set up quickly with only a minimum of site preparation needed. The spokesperson said, “As long as the base has been compacted, it can operate. The plant has everything it needs.”

Despite being smaller than the existing Prime 140, the new Prime 100 plant still features high-quality Ammann core components for high performance and a quality output.